Intelligent control sectional type adhesive tape die cutting process

An intelligent control and segmented technology, applied in metal processing, vibration suppression adjustment, spring/shock absorber, etc., can solve the problems of tape die-cutting process adaptation width and cumbersome die-cutting, etc., to reduce power requirements and The number of required control devices, the number of motors are reduced, and the effect of improving die-cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

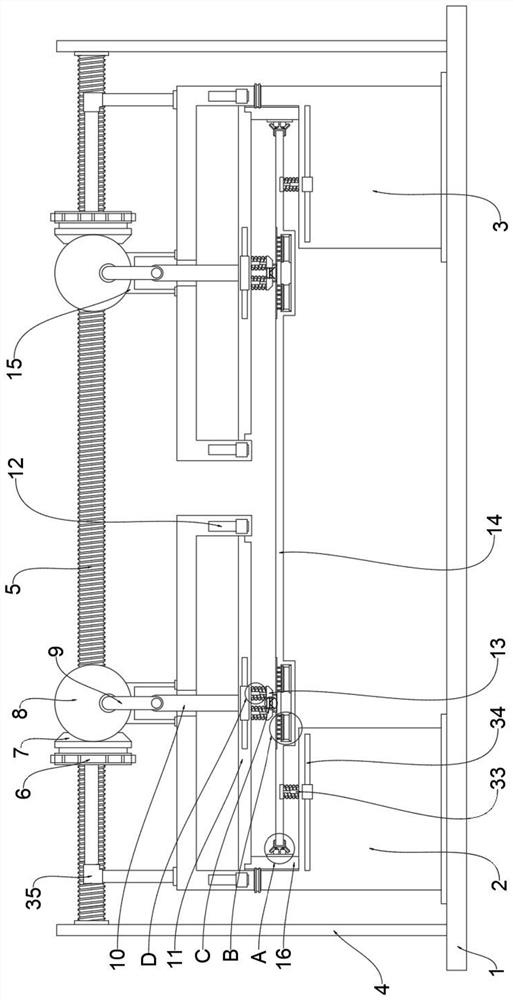

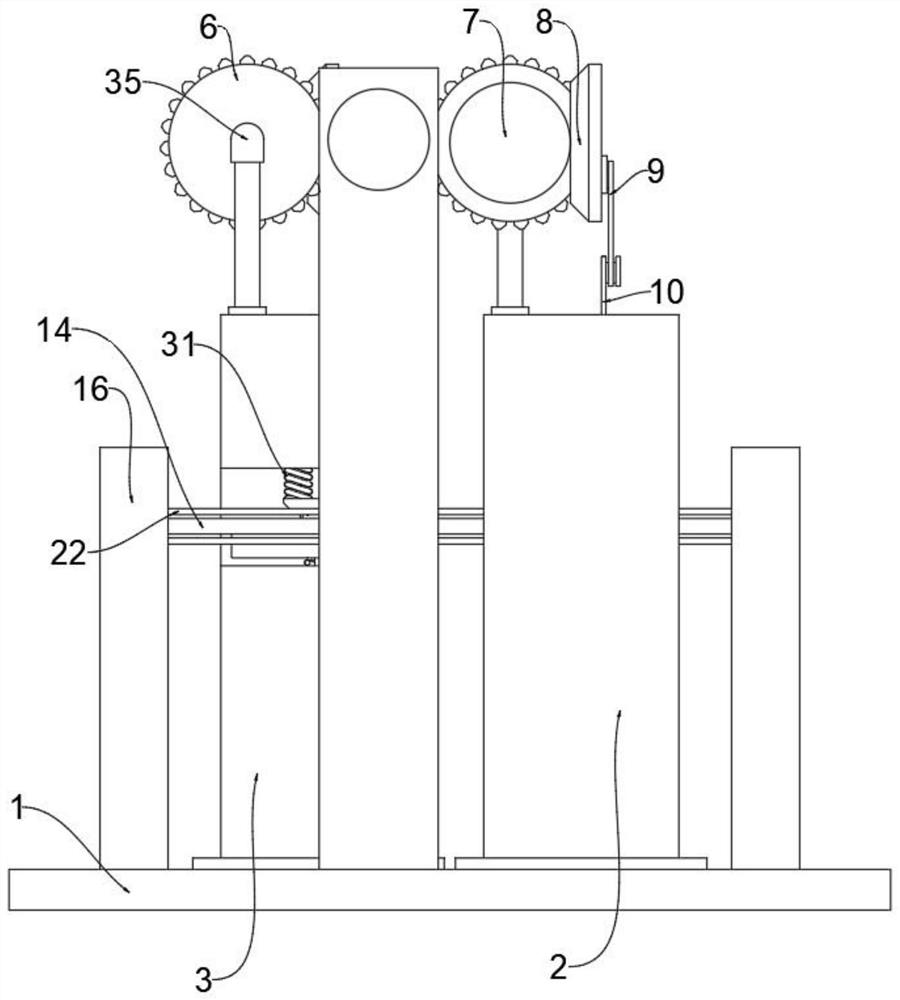

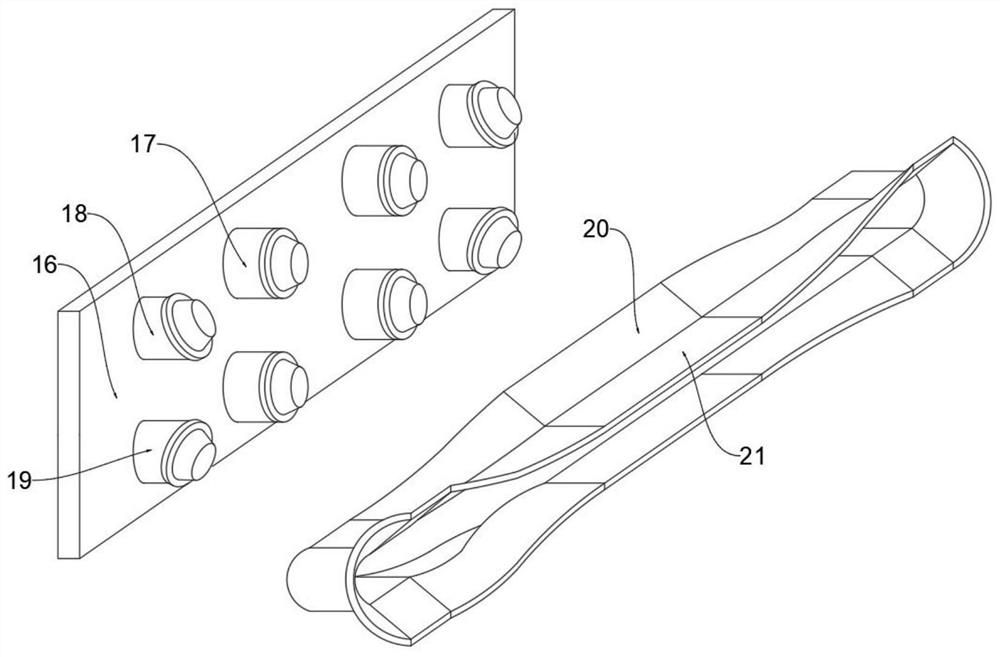

[0027] see Figure 1-7 , an embodiment provided by the present invention: an intelligently controlled segmented tape die-cutting process, including die-cutting position adjustment, tape conveying, segmental die-cutting and adhesive tape fixing, the tape die-cutting process includes tape Die-cutting device, adhesive tape die-cutting device comprises first support frame 2, second support frame 3 and transmission screw rod 5, and first support frame 2 and second support frame 3 all comprise die-cutting tool 13 and the first The fixed plate 11, the second transmission rod 10 and the first transmission rod 9, the second transmission bevel gear 8 can be drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com