Degradation method for polyethylene plastics

A polyethylene plastic and raw material technology, applied in the field of environmental protection, can solve pollution and other problems, and achieve the effect of easy contact degradation and secondary reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

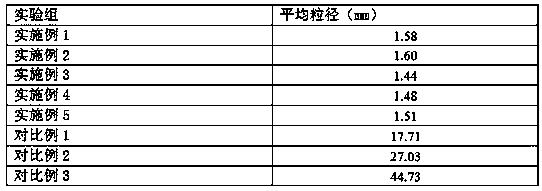

Examples

Embodiment 1

[0026] A method for degrading polyethylene plastics is characterized in that it comprises the following specific steps:

[0027] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0028] S2. Put the pretreated raw materials into the soaking solution for soaking for 24 hours, and keep the soaking temperature at 37°C;

[0029] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0030] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0031] The soaking solution in the step S2 includes the following components in parts by weight: calcium hydroxide 6, sodium hydroxide 9, ammonium chloride 6, ammonium bicarbonate 11, triethanolamine 5, and isopropanol 4.

[0032] Further, the concentration of the soaking solution is 0.12moL / L-0.46moL / L.

[0033] The soaking liquid in the present invention can be combined with the functi...

Embodiment 2

[0038] A method for degrading polyethylene plastics is characterized in that it comprises the following specific steps:

[0039] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0040] S2. Put the pretreated raw materials into the soaking solution for soaking for 72 hours, and keep the soaking temperature at 60°C;

[0041] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0042] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0043] The soaking solution in the step S2 includes the following components in parts by weight: calcium hydroxide 13, sodium hydroxide 15, ammonium chloride 18, ammonium bicarbonate 26, triethanolamine 19, and isopropanol 9.

[0044] Further, the concentration of the soaking solution is 0.46moL / L.

[0045] Further, the process of fermentation and degradation in the step S3 is: the total n...

Embodiment 3

[0049] A method for degrading polyethylene plastics is characterized in that it comprises the following specific steps:

[0050] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0051] S2. Put the pretreated raw materials into the soaking solution for soaking for 48 hours, and keep the soaking temperature at 49°C;

[0052] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0053] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0054] The soaking solution in the step S2 includes the following components in parts by weight: 10 calcium hydroxide, 12 sodium hydroxide, 12 ammonium chloride, 19 ammonium bicarbonate, 12 triethanolamine, and 7 isopropanol.

[0055] Further, the concentration of the soaking solution is 0.29moL / L.

[0056] Further, the fermentation degradation process in the step S3 is: the total number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com