Plastic degradation process

A process and plastic technology, applied in the field of plastic degradation process, can solve pollution and other problems, and achieve the effect of easy contact degradation and secondary reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

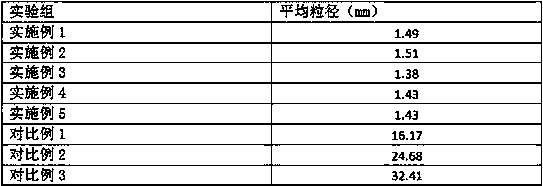

Examples

Embodiment 1

[0028] A plastic degradation process is characterized in that it comprises the following specific steps:

[0029] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0030] S2. Put the pretreated raw materials into the soaking solution for soaking for 24 hours, and keep the soaking temperature at 37°C;

[0031] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0032] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0033] The soaking solution in the step S2 includes the following components in parts by weight: calcium hydroxide 8, sodium hydroxide 6, ammonium chloride 13, ammonium bicarbonate 11, triethanolamine 9, polyethylene glycol 2.

[0034] Further, the concentration of the soaking solution is 0.15moL / L.

[0035] The soaking solution in the present invention can be combined with the functional groups of the...

Embodiment 2

[0045] A plastic degradation process is characterized in that it comprises the following specific steps:

[0046] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0047] S2. Put the pretreated raw materials into the soaking solution for soaking for 72 hours, and keep the soaking temperature at 60°C;

[0048] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0049] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0050] The soaking solution in the step S2 includes the following components in parts by weight: calcium hydroxide 17, sodium hydroxide 11, ammonium chloride 19, ammonium bicarbonate 21, triethanolamine 17, and polyethylene glycol 6.

[0051] Further, the concentration of the soaking solution is 0.36moL / L.

[0052] The soaking solution in the present invention can be combined with the functional groups...

Embodiment 3

[0057] A plastic degradation process is characterized in that it comprises the following specific steps:

[0058] S1. Sieve the collected plastic raw materials, clean them, and perform mechanical destruction to reduce their volume;

[0059] S2. Put the pretreated raw materials into the soaking solution for soaking for 48 hours, and keep the soaking temperature at 49°C;

[0060] S3. Cleaning the soaked raw materials, adding them to the fermenter for fermentation and degradation;

[0061] S4. Collect the degraded mixed solution, waiting for secondary extraction and recycling.

[0062] The soaking solution in the step S2 includes the following components in parts by weight: calcium hydroxide 13, sodium hydroxide 9, ammonium chloride 16, ammonium bicarbonate 16, triethanolamine 13, and polyethylene glycol 4.

[0063] Further, the concentration of the soaking solution is 0.255moL / L.

[0064] The soaking solution in the present invention can be combined with the functional groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com