Edge member and construction method of steel concrete shear wall

A technology of concrete shear walls and edge components, which is applied to building components, building structures, walls, etc., can solve the problems of low production efficiency, troublesome coordination, and unseen problems, and achieve the improvement of building industrialization level, fast construction speed, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

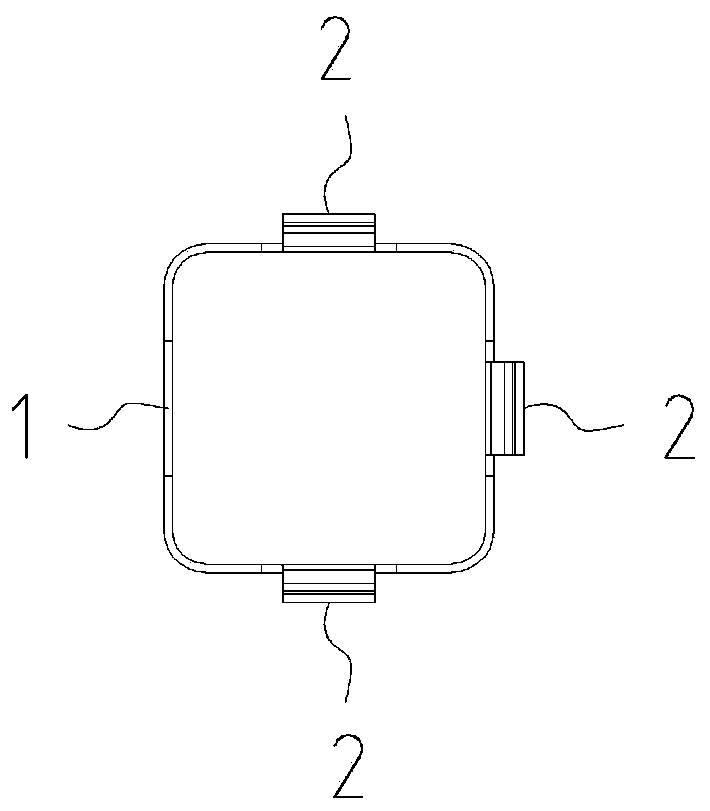

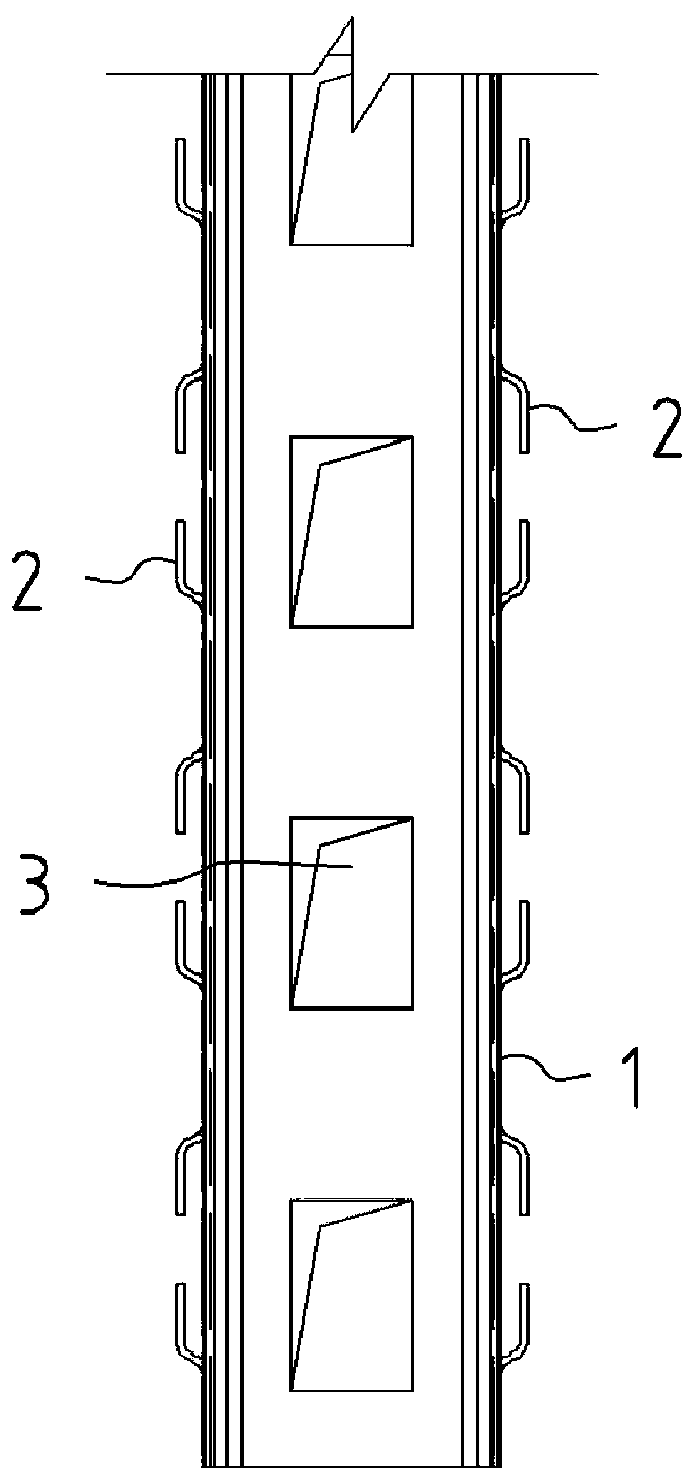

[0056] Example 1: Constructing the edge member of the concrete shear wall with open square steel pipe 1

[0057] Such as Figure 11 to Figure 17 as shown,

[0058] Step 1. Arranging open square steel pipe 1 and binding steel bars

[0059] According to the area of the longitudinal force-bearing reinforcement required by the structural design, the opening square steel pipe 1 of the edge member of the shear wall is arranged according to the principle of equal strength. The connection between the upper and lower sides of the opening square steel pipe 1 can be inserted with a small section square steel pipe After welding or bolting, additional steel bars can also be added at the joint to realize the lap joint connection under the force of the structure;

[0060] The longitudinal reinforced steel bars of the edge members of the shear wall are all replaced by open-hole square steel pipes 1. The horizontal steel bars include the stirrups 81 of the edge members and the horizontally...

Embodiment 2

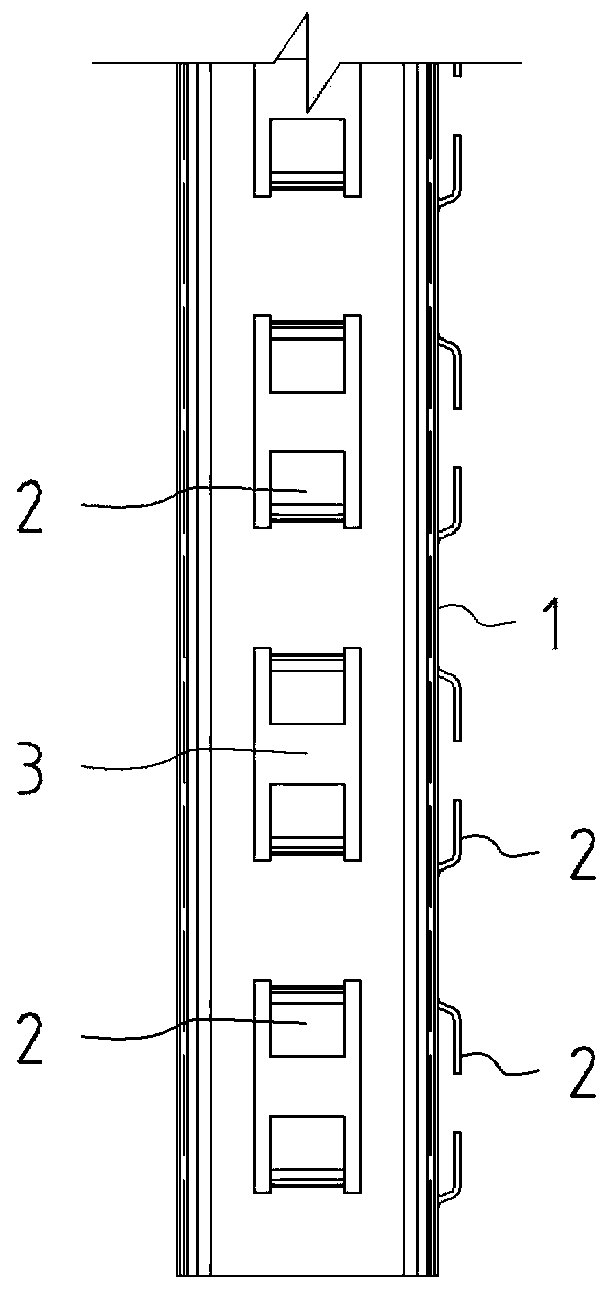

[0065] Example 2: Using thin-walled steel trusses 4 to construct edge members of concrete shear walls

[0066] Such as Figure 21 to Figure 23 As shown, when the shear wall connecting beam is connected with the edge member, the use of open square steel pipe 1 will affect the reinforcement arrangement of the shear wall connecting beam. In this case, the thin-walled steel truss 4 is used to construct the edge member of the concrete shear wall ,

[0067] Step 1. Arranging thin-walled steel trusses 4 and binding steel bars

[0068] The thin-walled steel trusses 4 of the edge members of the shear wall are arranged according to the area of the longitudinal force-bearing reinforcement required by the structural design, and the connection between the upper and lower sides of the thin-walled steel trusses 4 can be made of small-section thin-walled steel trusses. 4. Welding or bolting after inserting, it is also possible to add additional steel bars at the joint to realize the lap j...

Embodiment 3

[0074] Embodiment three, the construction process of shear wall body

[0075] Such as Figure 18 to Figure 20 As shown, the concrete shear wall body is constructed with thin-walled steel trusses 4,

[0076] Step 1. Arranging thin-walled steel trusses 4 and binding steel bars

[0077] According to the area of vertically distributed steel bars in the shear wall body that needs to be set in structural design, the thin-walled steel trusses 4 of the shear wall body are arranged according to the principle of equal strength, and the connection between the upper and lower sides of the thin-walled steel trusses 4 can be small The cross-section thin-walled steel truss 4 is welded or bolted after being inserted, and additional steel bars can also be added at the joint to realize the lap joint connection of the structural force;

[0078] The vertically distributed steel bars of the shear wall body are all replaced by thin-walled steel trusses 4, and the horizontally distributed steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com