Guiding straightening device

A conduit and guide rail technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of large manual workload, inability to meet automatic workover, low degree of automation, etc., saving labor, saving make-up and unloading The effect of deducting time and opening high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

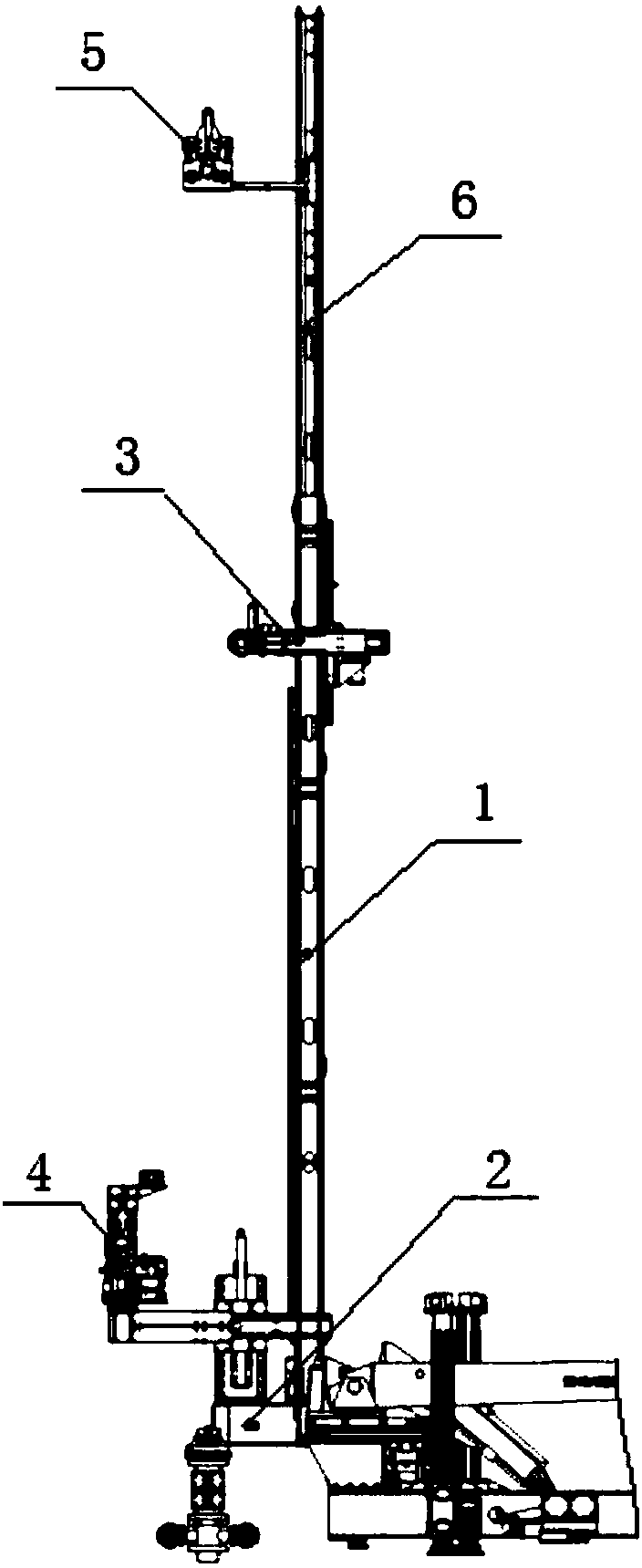

[0020] figure 1 Shown is the structural representation of the present invention.

[0021] The invention provides a guiding device, which includes a guiding base 1, a guiding conduit 2, an upper guiding 3, a lower guiding 4, an elevator 5 and a hydraulic control system.

[0022] The guide catheter 2 is a retractable structure, the upper guide guide 3 is arranged on the upper part of the guide guide 2, and the lower guide guide 4 is arranged on the lower part of the guide guide guide 2; The telescopic conduit 6 can be lifted to the working position by the lifting cylinder; the top of the telescopic conduit 6 is provided with a pulley, and one end of the rope is connected with a small winch arranged in the guide conduit 4, and the other end of the rope is passed around the pulley, It is connected with the elevator 5; the bottom of the guide guide 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com