Online monitoring system for deformation of transmission line tower material

A transmission line iron tower and monitoring system technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of iron tower tower material deformation, tower material breakage, failure not necessarily found in time, etc., to achieve the effect of ensuring safe and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

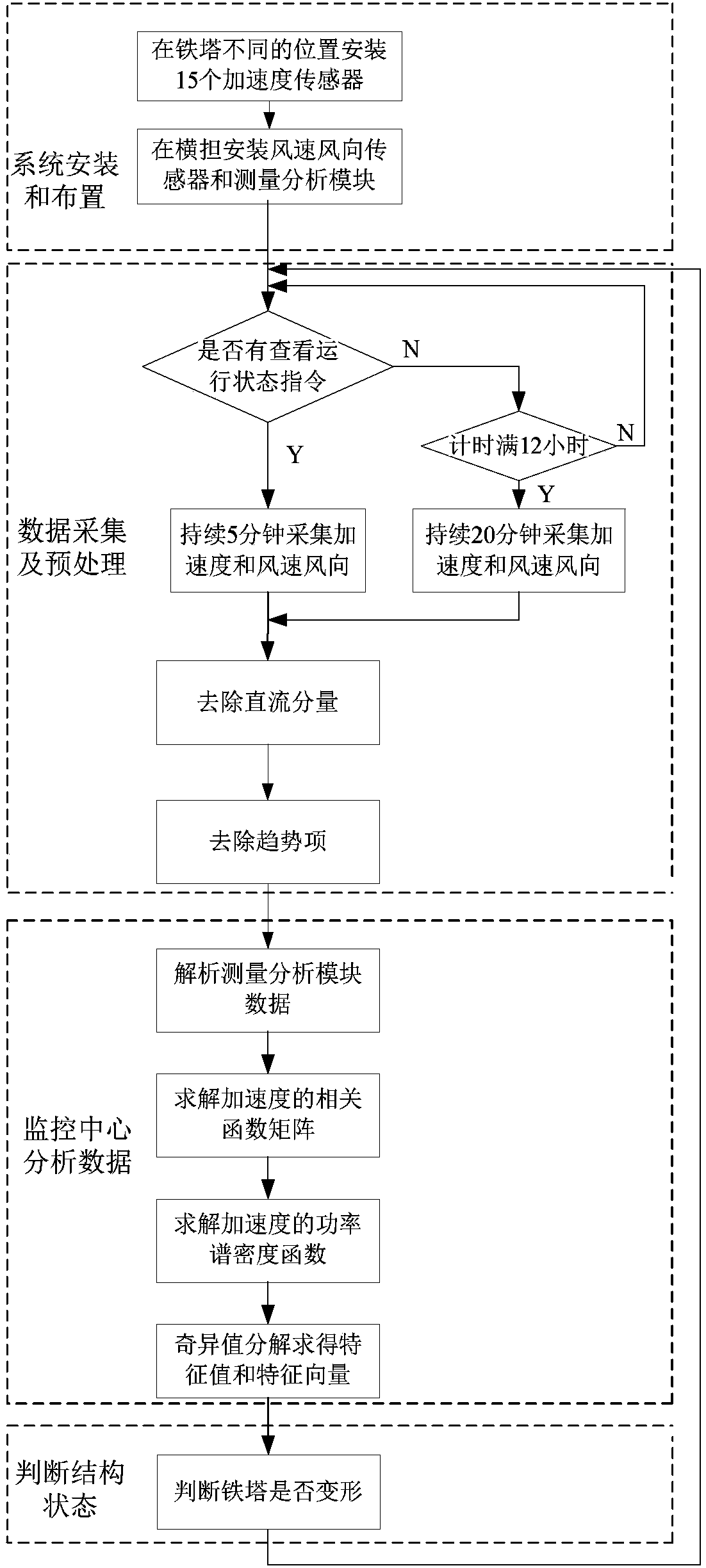

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

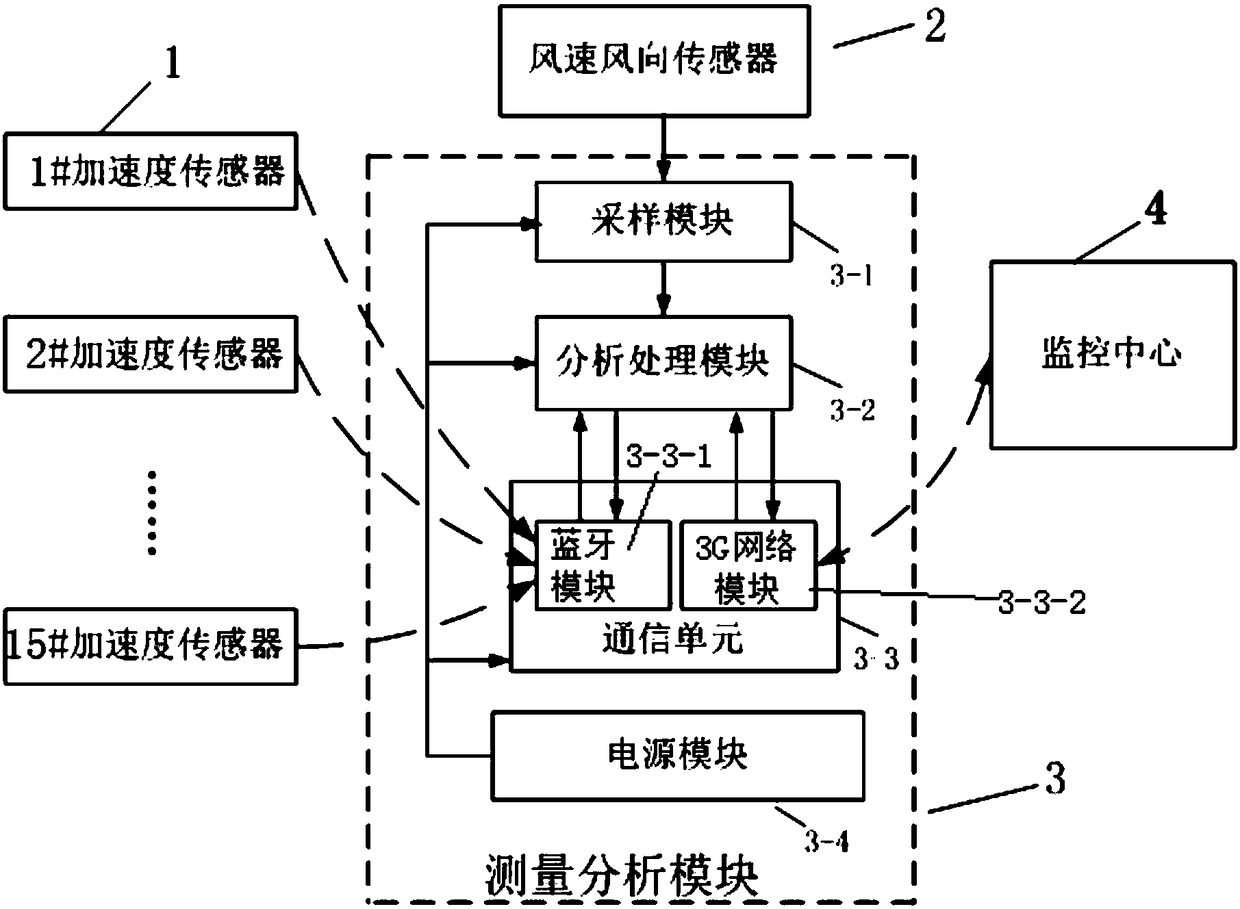

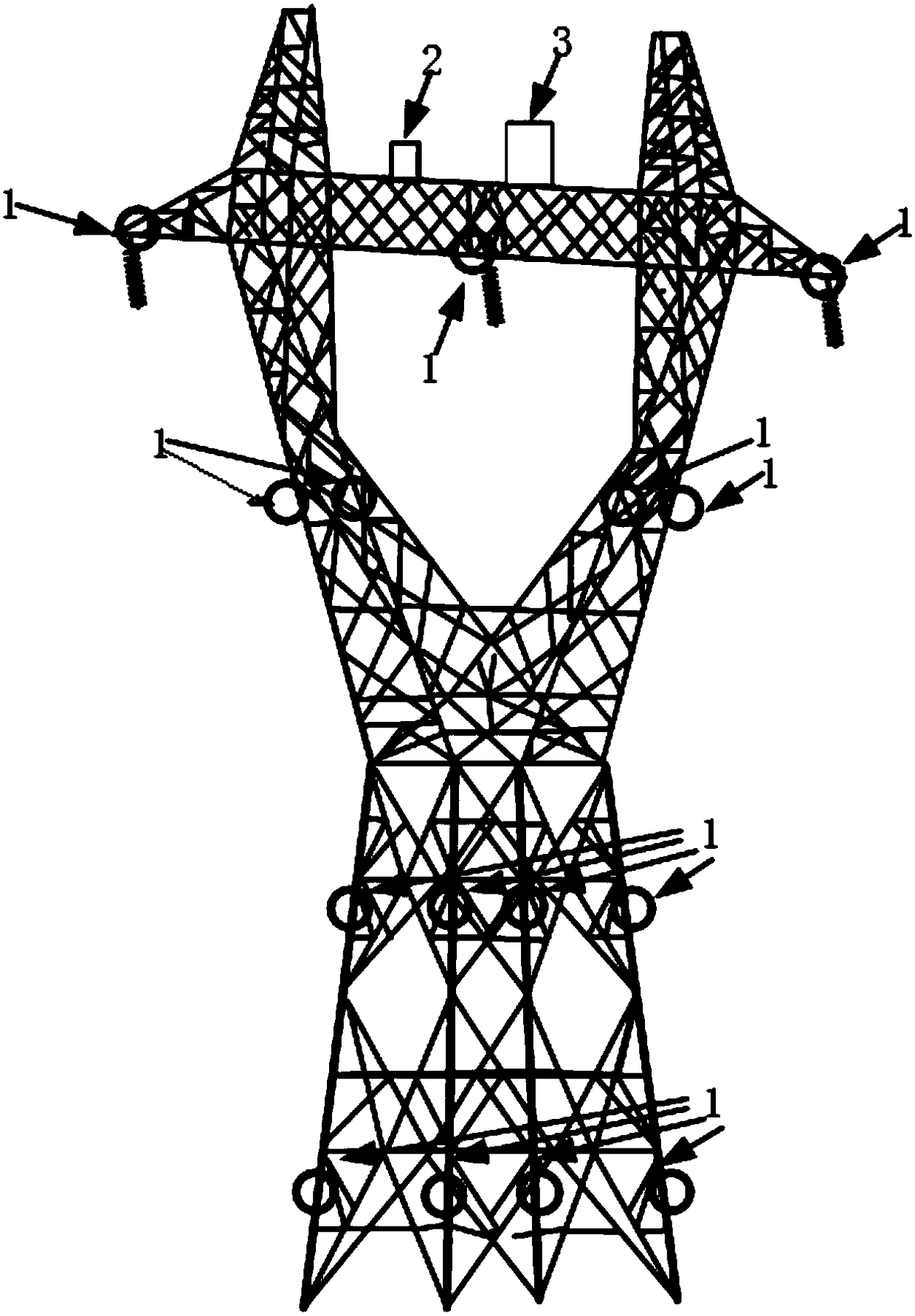

[0057] The online monitoring system for the deformation of the transmission line iron tower tower material of the present invention, such as figure 1As shown, it includes a measurement analysis module 3 and a wind speed and direction sensor 2 connected thereto, a monitoring center 4 and several wireless acceleration sensors 1 arranged at different positions of the transmission tower. Among them, the wireless acceleration sensor 1 is installed at 15 key positions of the transmission tower to measure the vibration acceleration at these positions.

[0058] The structure of the measurement analysis module 3 includes a sampling module 3-1, an analysis processing module 3-2 and a communication unit 3-3 connected in sequence, and the sampling module 3-1, the analysis processing module 3-2 and the communication unit 3-3 are respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com