Loose rock core slice specimen and manufacture method thereof

A production method and a technology for slicing specimens, which are applied to the production of loose core slice specimens and the field of loose core slice specimens, can solve problems such as difficulty in forming slice preservation, and achieve the effects of optimizing appearance, ensuring integrity, and excellent transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

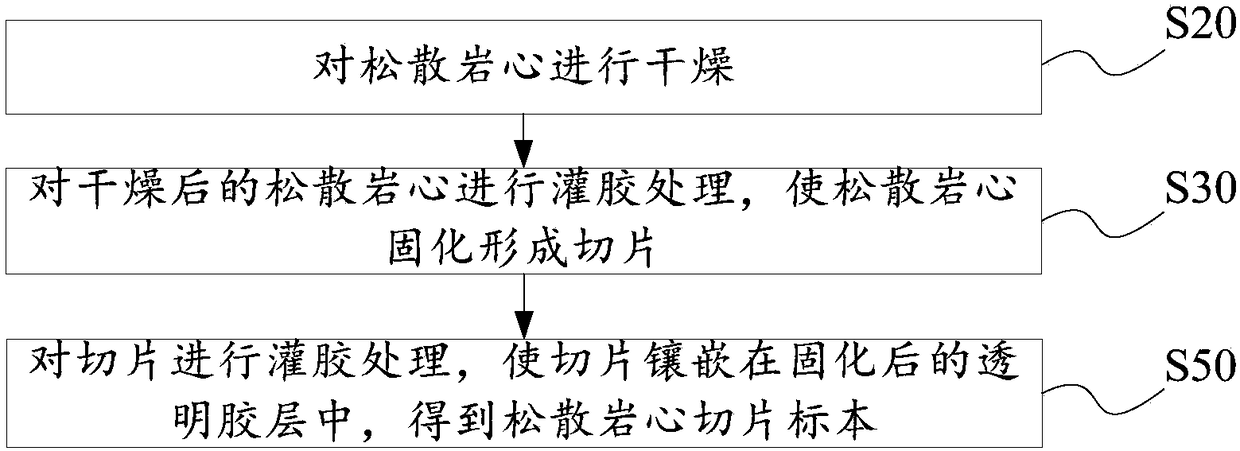

[0150] Embodiment one (as Figure 11 shown)

[0151] Figure 11 A method for preparing a clay core slice sample or a sandy soil core slice sample when the slice thickness is less than or equal to a preset thickness is shown:

[0152] Step S102, using two semi-cylindrical tubes to wrap the loose core out of the well to obtain a cylindrical core, wherein the loose core is a clay core;

[0153] Step S104, cutting along the longitudinal section of the cylindrical core to obtain a loose core with a section, and putting the core into a core box;

[0154] Step S20, drying the loose rock core (wherein, the loose rock core is placed in a cool place to dry naturally, and the room temperature is preferably kept between 15°C-30°C, generally 5-10 days is appropriate, and it can be seen from the surroundings of the rock core that the core already dry, keep the core label);

[0155] Step S302, modifying and smoothing the section of the loose core, and cleaning the corner debris;

[0156...

Embodiment 2

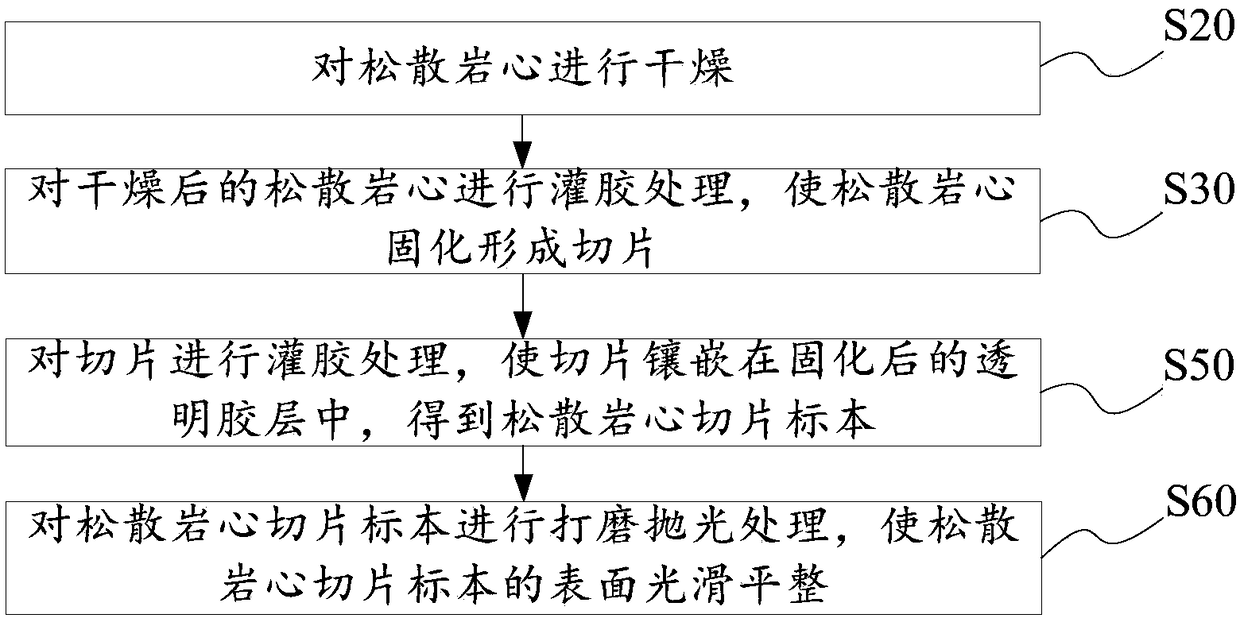

[0167] Embodiment two (as Figure 12 shown)

[0168] Figure 12 The preparation method of the clay core slice specimen when the slice thickness is greater than the preset thickness is shown:

[0169] Step S102, using two semi-cylindrical tubes to wrap the loose core out of the well to obtain a cylindrical core, wherein the loose core is a clay core;

[0170] Step S104, cutting along the longitudinal section of the cylindrical core to obtain a loose core with a section, and putting the core into a core box;

[0171] Step S20, drying the loose core, where the loose core is placed in a cool place to dry naturally, and the room temperature is preferably kept between 15°C-30°C, generally 5-10 days is appropriate, and it can be seen from the surroundings of the core Has been dried, keep the core label;

[0172] Step S302, modifying and smoothing the section of the loose core, and cleaning the corner debris;

[0173] Step S304, pouring the transparent resin glue on the surface o...

Embodiment 3

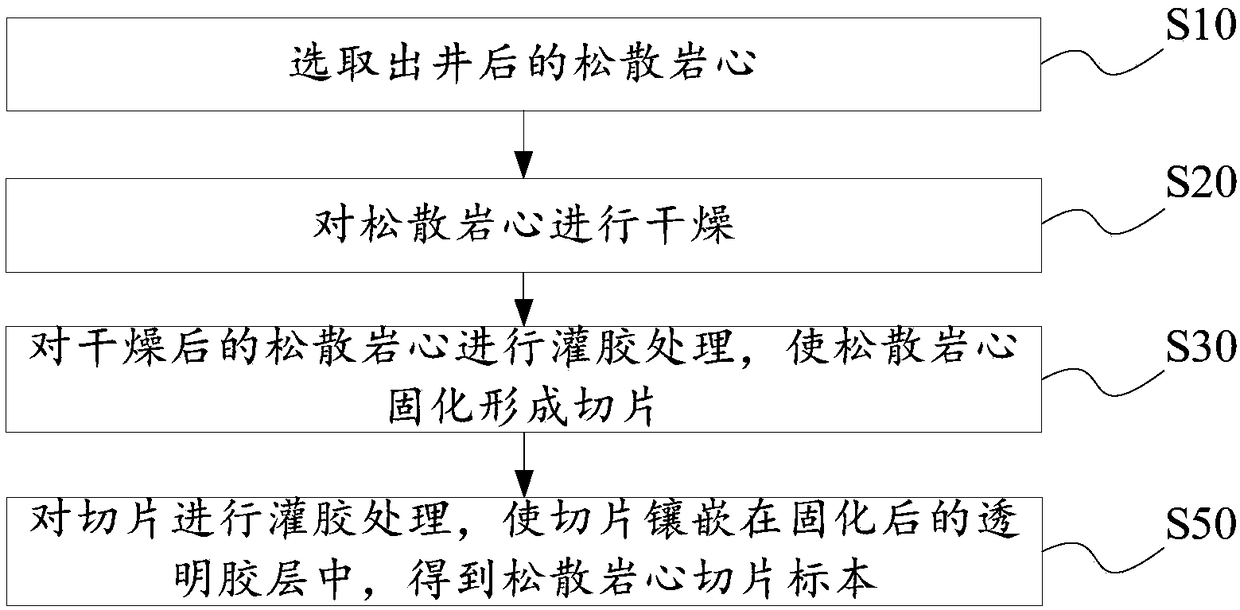

[0188] Embodiment three (as Figure 13 shown)

[0189] Figure 13 The preparation method of the sand core slice specimen when the slice thickness is greater than the preset thickness is shown:

[0190] Step S102, using two semi-cylindrical tubes to wrap the loose core out of the well to obtain a cylindrical core; wherein the loose core is a sand core;

[0191] Step S104, cutting along the longitudinal section of the cylindrical core to obtain a loose core with a section, and putting the core into a core box;

[0192] Step S20, drying the loose core, where the loose core is placed in a cool place to dry naturally, and the room temperature is preferably kept between 15°C-30°C, generally 5-10 days is appropriate, and it can be seen from the surroundings of the core Has been dried, keep the core label;

[0193] Step S302, modifying and smoothing the section of the loose core, and cleaning the corner debris;

[0194] Step S304, pouring the transparent resin glue on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com