Specimen for pure II type dynamic breaking and experiment method

An experimental method and test piece technology, applied in the field of material mechanics, can solve the problems of pure type II fracture of samples that cannot ensure data accuracy, difficult to measure transmission waveform, difficult to measure accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

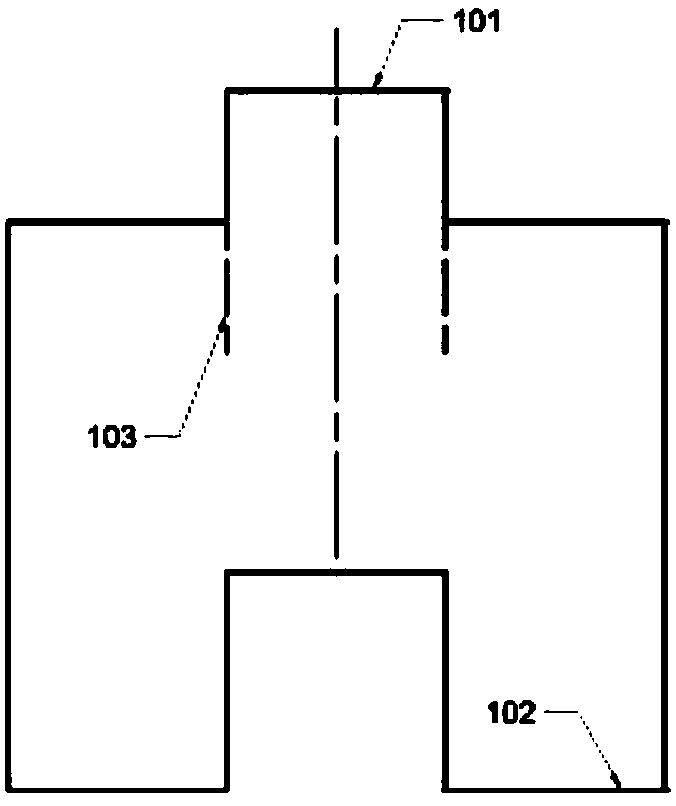

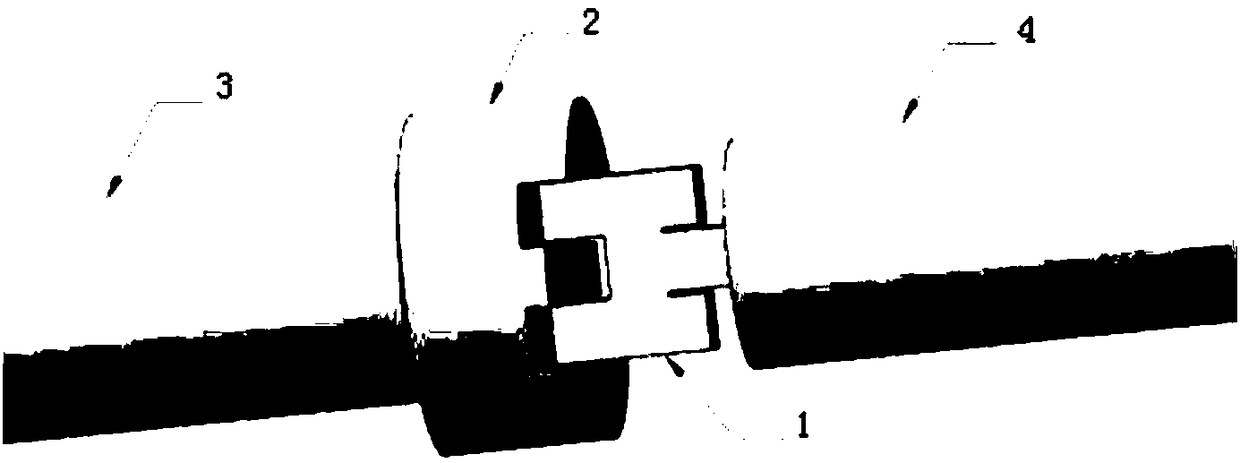

[0017] The present invention proposes a novel fracture specimen and matching fixtures for pure type II experiments, such as figure 1 and figure 2 As shown, sample 1 and fixture 2 are both axisymmetric structures. Sample 1 has a loading end 101 and two supporting ends 102, and the surface of sample 1 is polished to reduce friction with the end surface of the rod during the experiment.

[0018] Make two prefabricated cracks 103 on both sides of the loading end 101 of the pattern 1, figure 1 The dotted line in the middle is the prefabricated crack 103 processed by wire cutting, with a width of 0.3 mm. In order to prevent the lateral displacement of sample 1 and the generation of type I components, a matching fixture 2 was designed and used in conjunction with it in the experiment. One end of the clamp 2 is a round tube 201, the inner diameter of which is the same as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com