Device for testing thermal shock resistance of batch test pieces

A technology of thermal shock resistance and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, instruments, etc., can solve the problems of high temperature radiation of heating furnace, less characterization results of thermal shock resistance performance, and the inability to adjust the initial ambient temperature of thermal shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

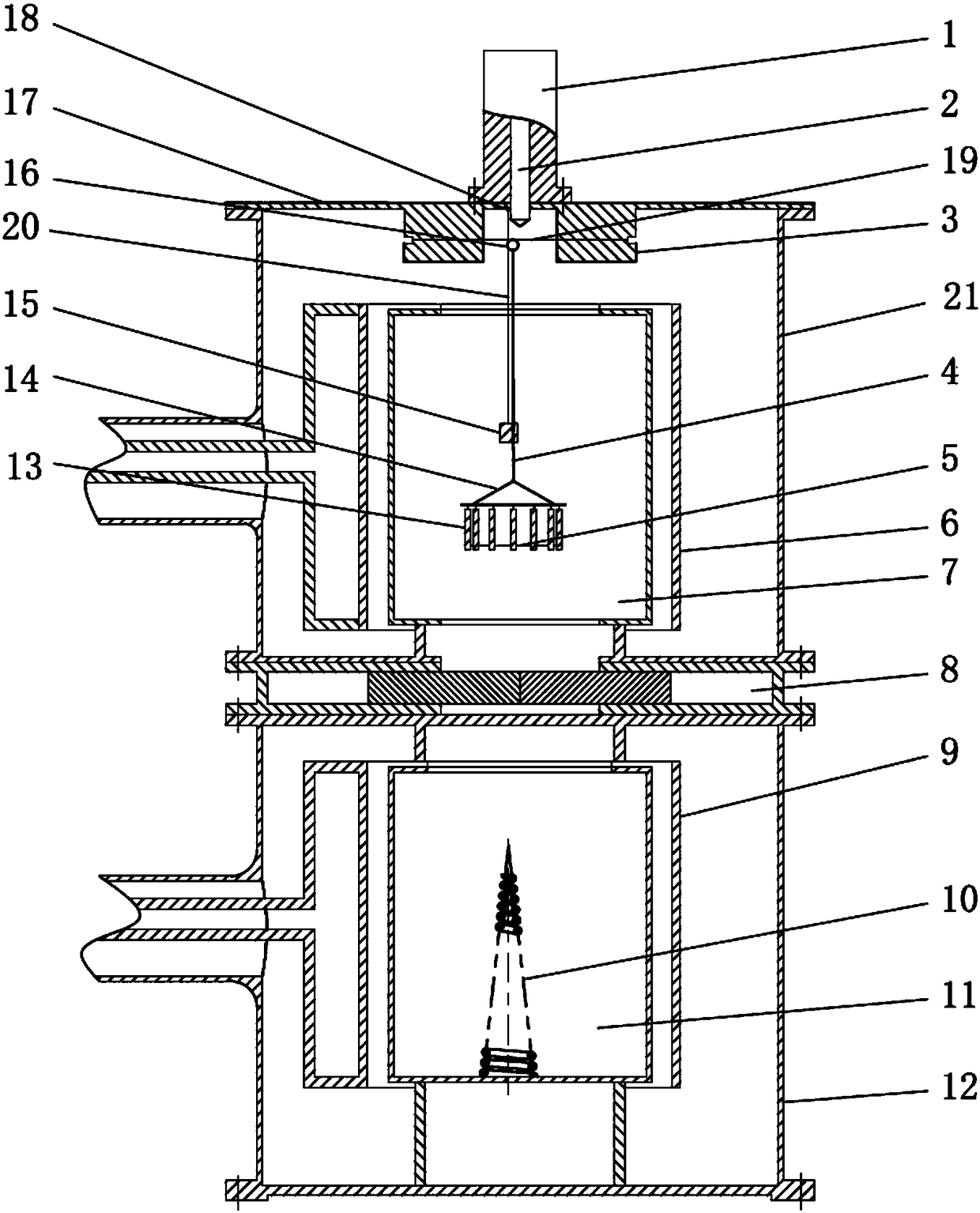

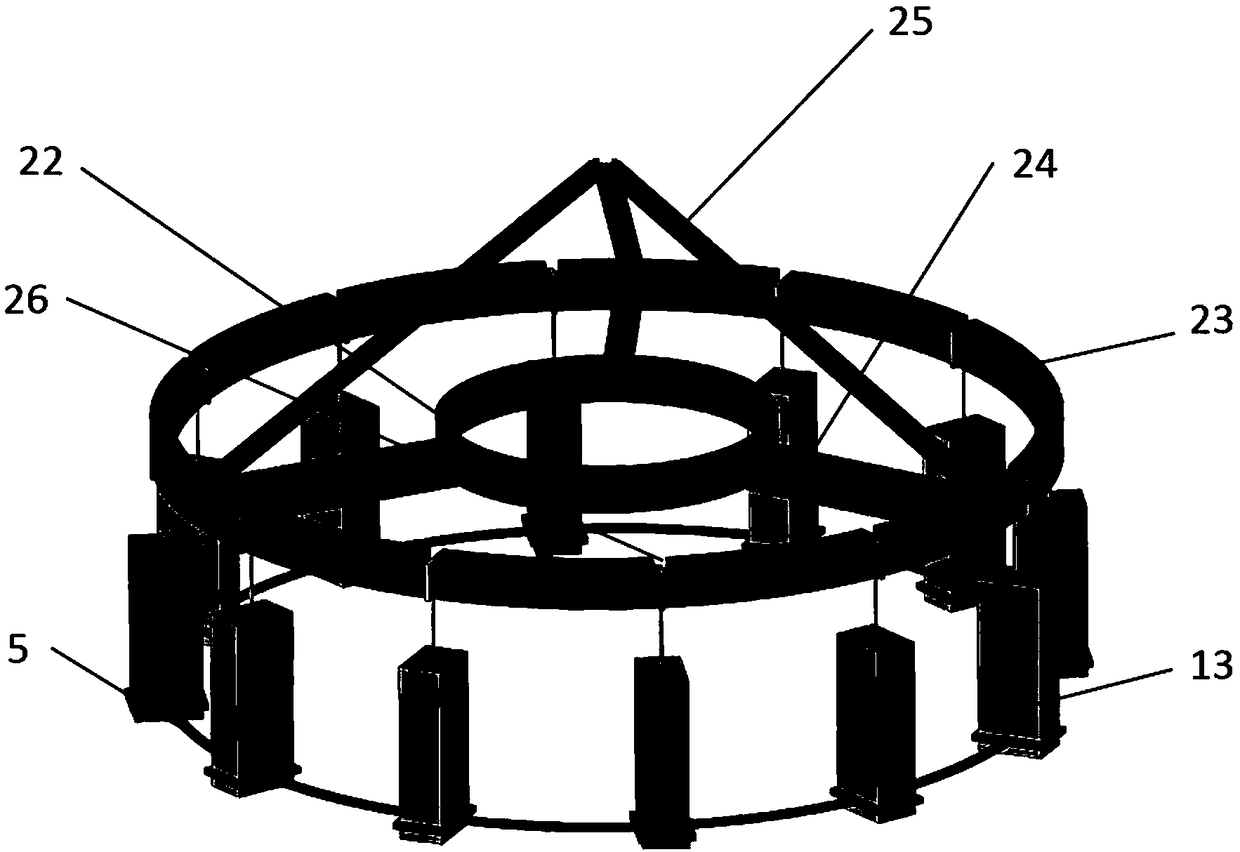

[0016] Such as figure 1 As shown, the present invention includes upper two sealed furnaces 21 and a lower sealed furnace 12, the two sealed furnaces are vertically connected in series, a sealed and heat-insulated door 8 is arranged in the middle, and a furnace door 17 is installed on the top, and the furnace door 17 is fixed A cylinder 1 is installed, and the pneumatic plunger 2 in the cylinder 1 can extend into the upper sealing furnace 21; the upper heating furnace 6 in the upper sealing furnace 21 can build an upper high temperature chamber 7, and there is a specimen rack 14 in the upper high temperature chamber 7 . Furnace door 17 lower surfaces have suspension wire column 3, suspension wire two 19 two ends are fixed on the suspension wire column 3, suspension wire three 20 tops are fixed on the furnace door 17, and a weight 15 is hung on the lower end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com