Automatic biasing microbial coupled photoelectrocatalysis fuel cell pollution control system and electrode preparation method

A photoelectric catalysis and fuel cell technology, applied in biochemical fuel cells, battery electrodes, chemical instruments and methods, etc., can solve problems such as poor electricity generation performance, low degradation efficiency, and poor effluent quality, so as to promote the development of electronics and Effects of hole separation, efficient degradation, enhanced absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

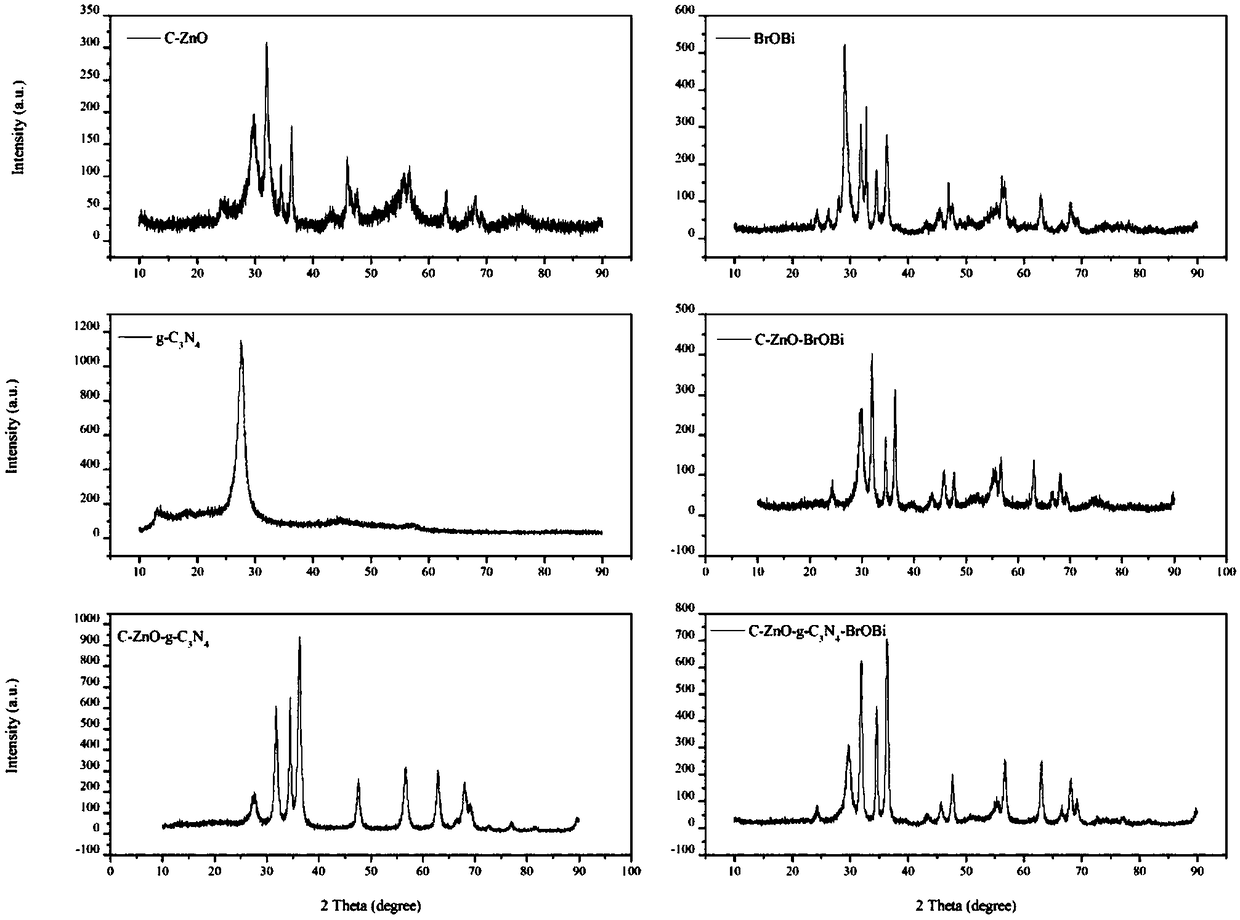

[0027] C-ZnO-g-C 3 N 4 - Preparation of BiOBr photocatalytic powder:

[0028] (1) g-C 3 N 4 Preparation: Weigh 5.0g of melamine, grind it, pass through a 300-mesh sieve, and put it in a crucible. The crucible was calcined in a muffle furnace at 550 °C for 4 hours at a heating rate of 5 °C min -1 . After cooling down, the crucible was taken out, and ground through a 300-mesh sieve to obtain a yellow powder.

[0029] (2) C-ZnO-g-C 3 N 4 Preparation: Mix 5mL of ethylene glycol (EG) and 75mL of ethanol and stir for 30 minutes, then add 0.654g of zinc acetate dihydrate to the mixed liquid, and mix in 0.08g of g-C 3 N 4 After stirring for 30 minutes, the clear solution was transferred to a 100 mL polytetrafluoroethylene-lined autoclave and heated at 180 °C for 12 hours in a forced-air drying oven. The precipitate was separated by suction filtration with a circulating water vacuum pump, and washed with absolute ethanol and deionized water several times. The precipitate was...

Embodiment 2

[0033] The C-ZnO-g-C prepared by embodiment 1 3 N 4 -BiOBr photocatalytic powder is evenly attached to the surface of carbon fiber cloth after hydrothermal pretreatment.

[0034] Self-bias microbial coupling photocatalytic fuel cell pollution control system operation: Add 400ml of simulated wastewater containing 10mg / L rhodamine B to the cathode chamber of a 100mm*50mm*200mm double-chamber reactor. C-ZnO-g-C 3 N 4 -The BiOBr electrode is used as the cathode, and Shewanella is filled in the anode chamber and placed on the other side of the reactor. The external circuit is connected to a 10Ω resistor. The light source uses a 50W cold reflective tungsten halogen lamp / ultraviolet lamp. The distance between the light source is 5cm, and the bottom of the reactor lasts Aeration provides sufficient dissolved oxygen for electronic activation of oxygen to generate oxygen free radicals. Before the reaction starts, expose to air and stir, avoid light and absorb for 30 minutes to reach...

Embodiment 3

[0037] The composition of the reaction system described in Example 2 is the same. Add 400 mL of tetracycline hydrochloride to the cathode chamber as simulated wastewater. Before the reaction starts under dark conditions during operation, aerate and stir, and absorb in the dark for 30 minutes to reach adsorption-desorption equilibrium. Samples were taken every 30 minutes for liquid chromatography analysis. Such as Figure 9 As shown, the degradation of tetracycline in the first 30 minutes is relatively low, mainly because the adsorption process of tetracycline is catalyzed by the electrode, and tetracycline can be degraded by 85% in 30 minutes. This implementation case found that this catalytic electrode still has a high degradation rate for other types of pollutants, so the quaternary coupling photocatalytic electrode C-ZnO-g-C 3 N 4 -BiOBr can be applied to the removal of other different types of pollutants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com