Hole plugging method of printed circuit board

A technology for printed circuit boards and circuit boards, which is applied in the fields of printed circuits, printed circuits, and printed circuit manufacturing. Uniform and flat appearance of plug holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, further illustrate the present invention.

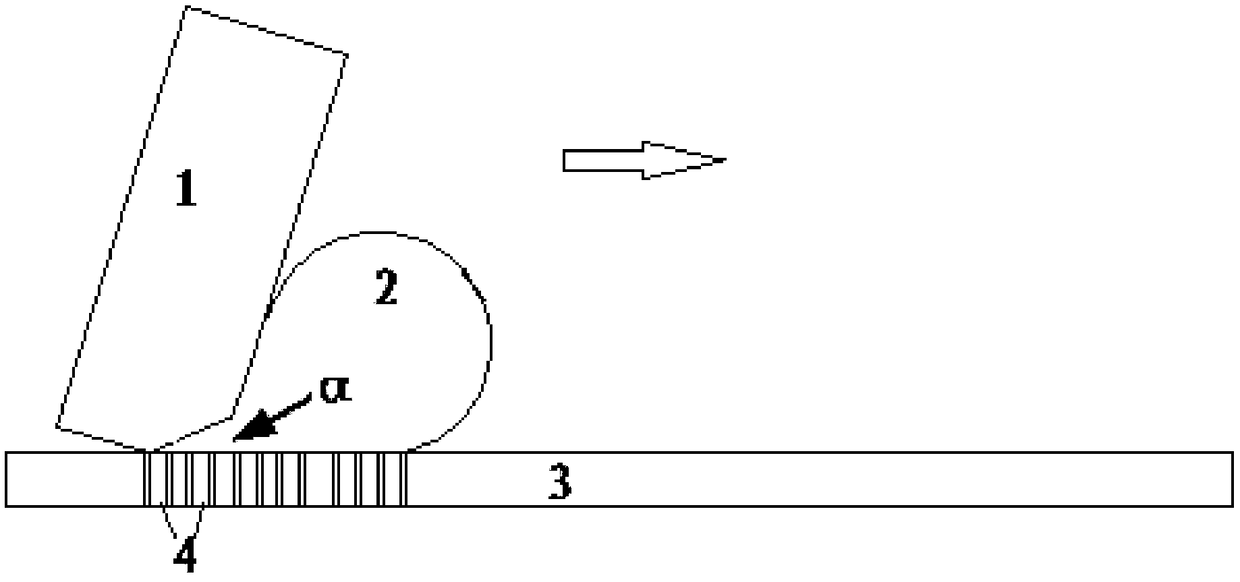

[0030] As shown in the figure, a plugging method of a printed circuit board is characterized in that the method comprises the following steps:

[0031] Step 1, preparation of plugging ink

[0032] Step 2, surface treatment of the printed circuit board, using a cleaning device to clean the circuit board (3) to be plugged to remove surface impurities;

[0033] Step 3, an air extraction device is arranged at the bottom of the cleaned circuit board in step 2, and the air extraction hole of the air extraction device is correspondingly arranged with the plug hole (4) of the circuit board;

[0034] Step 4, setting a stencil on the printing surface of the surface-treated circuit board in step 2, so that the filling port on the stencil is set correspondingly to the plug hole (4) of the circuit board;

[0035] Step 5, place the plug hole ink prepared in step 1 on the screen, move the scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com