Remote monitoring and control system based on augmented reality

An augmented reality and remote monitoring technology, applied in manufacturing tools, instruments, design optimization/simulation, etc., can solve problems such as inability to meet remote path planning, and achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

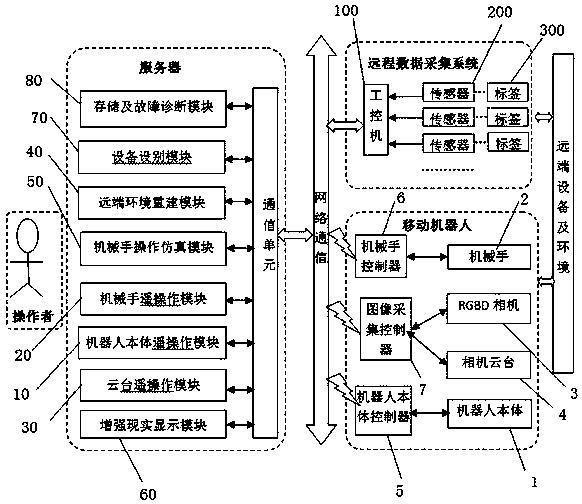

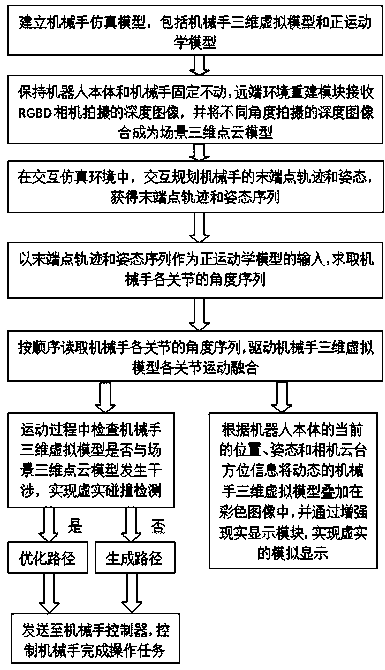

[0036] See figure 1 with figure 2 , A remote monitoring and control system based on augmented reality, including an interactive simulation control mode, which uses a server and a mobile robot located in the remote device and environment to complete the local path planning of the remote operation of the manipulator 2 in a virtual and real way And simulation, specifically:

[0037] The mobile robot includes a robot body 1, and a manipulator 2 and an RGBD camera 3 arranged on the robot body 1;

[0038] The server includes a remote environment reconstruction module 40, a manipulator operation simulation module 50, and an augmented reality display module 60; the remote environment reconstruction module 40 receives the depth images taken by the RGBD camera 3 and captures depth images from different angles. Image synthesis scene three-dimensional point cloud model, the manipulator operation simulation module 50 establishes a manipulator simulation model, and then combines the scene three...

Embodiment 2

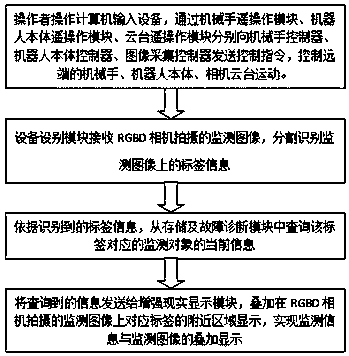

[0055] See figure 1 with image 3 The difference between this embodiment and the first embodiment is that the second embodiment can execute the monitoring mode while executing the interactive simulation control mode, and the interactive simulation mode will not be described again.

[0056] The monitoring mode completes the fusion display of monitoring data and monitoring images through the remote data acquisition system located in the remote equipment and the environment, the server and the mobile robot, and the combination of virtual and real. The monitoring images can be pictures and / Or video. specifically:

[0057] The remote data collection system includes an industrial computer 100 and a sensor 200, each of the sensors 200 is connected to the industrial computer 100, each monitoring object is provided with the sensor 200, and each sensor 200 is correspondingly provided with a tag 300; The label 300 includes asymmetrical labels 300 such as QR codes and barcodes;

[0058] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com