Cooling device for film blowing equipment

A cooling device and equipment technology, which is applied in the field of cooling devices, can solve problems such as high pressure of viscous fluid film blanks, tearing of film bubbles, unstable shape of film bubbles, etc., and achieve the best effect of uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

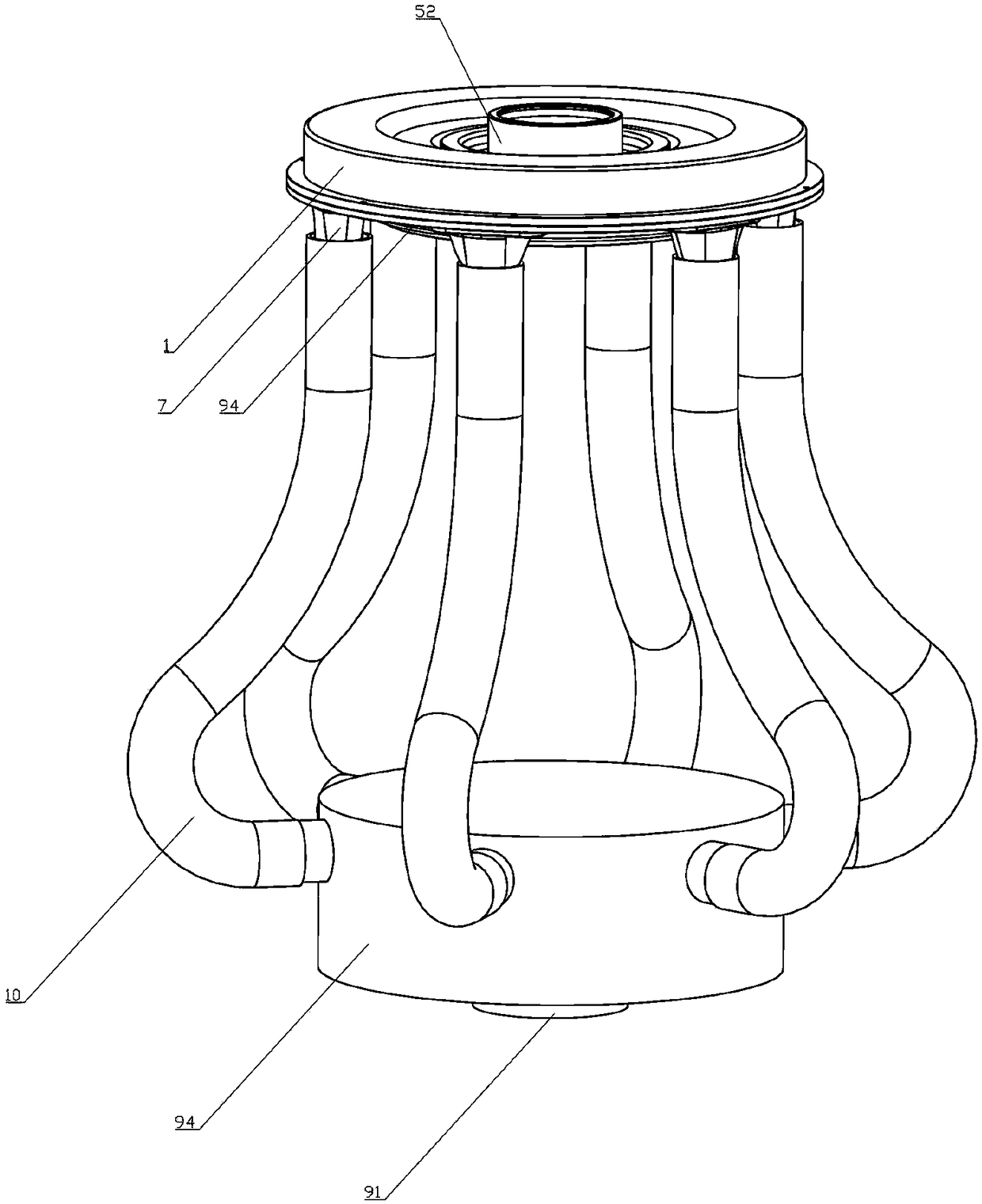

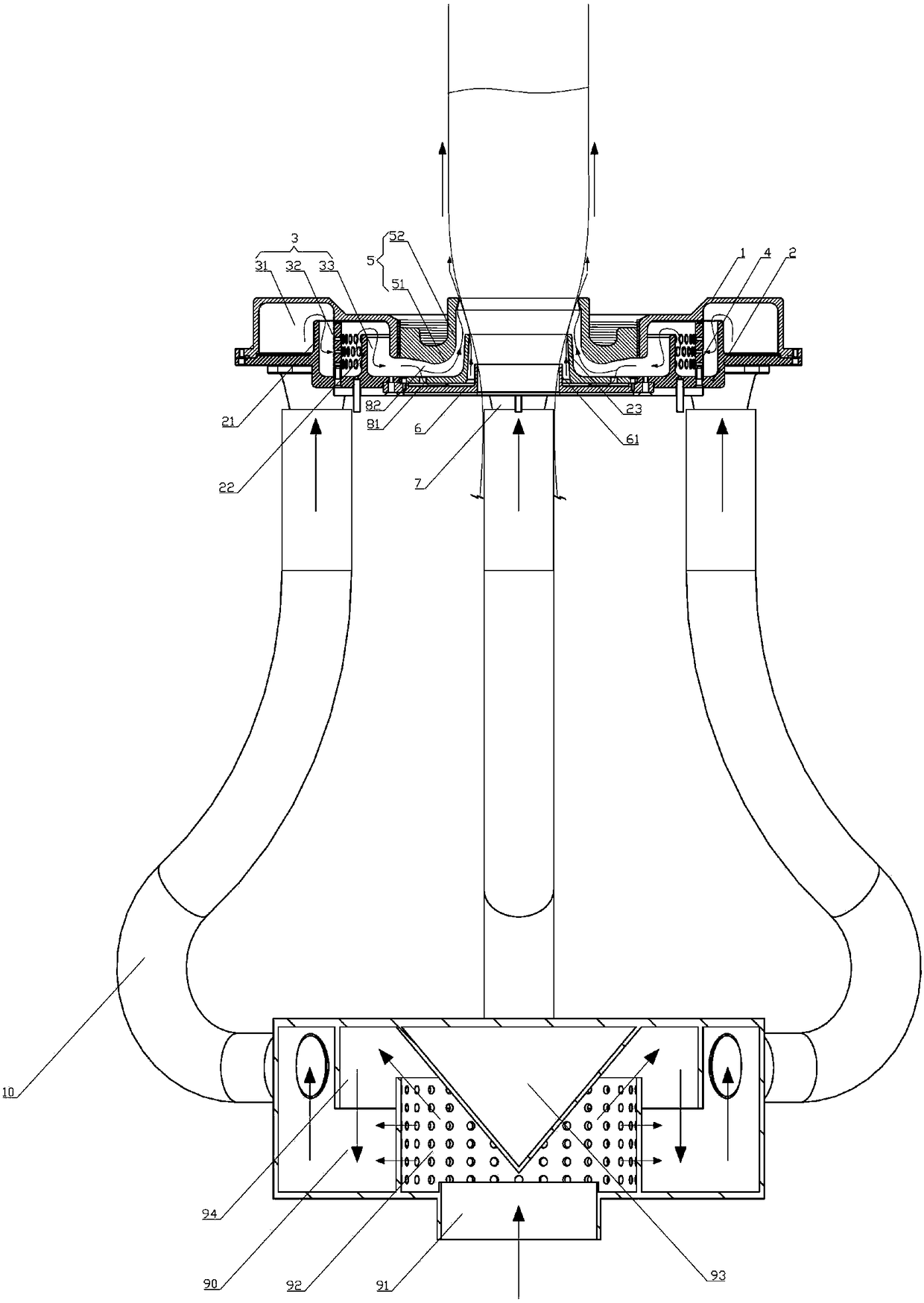

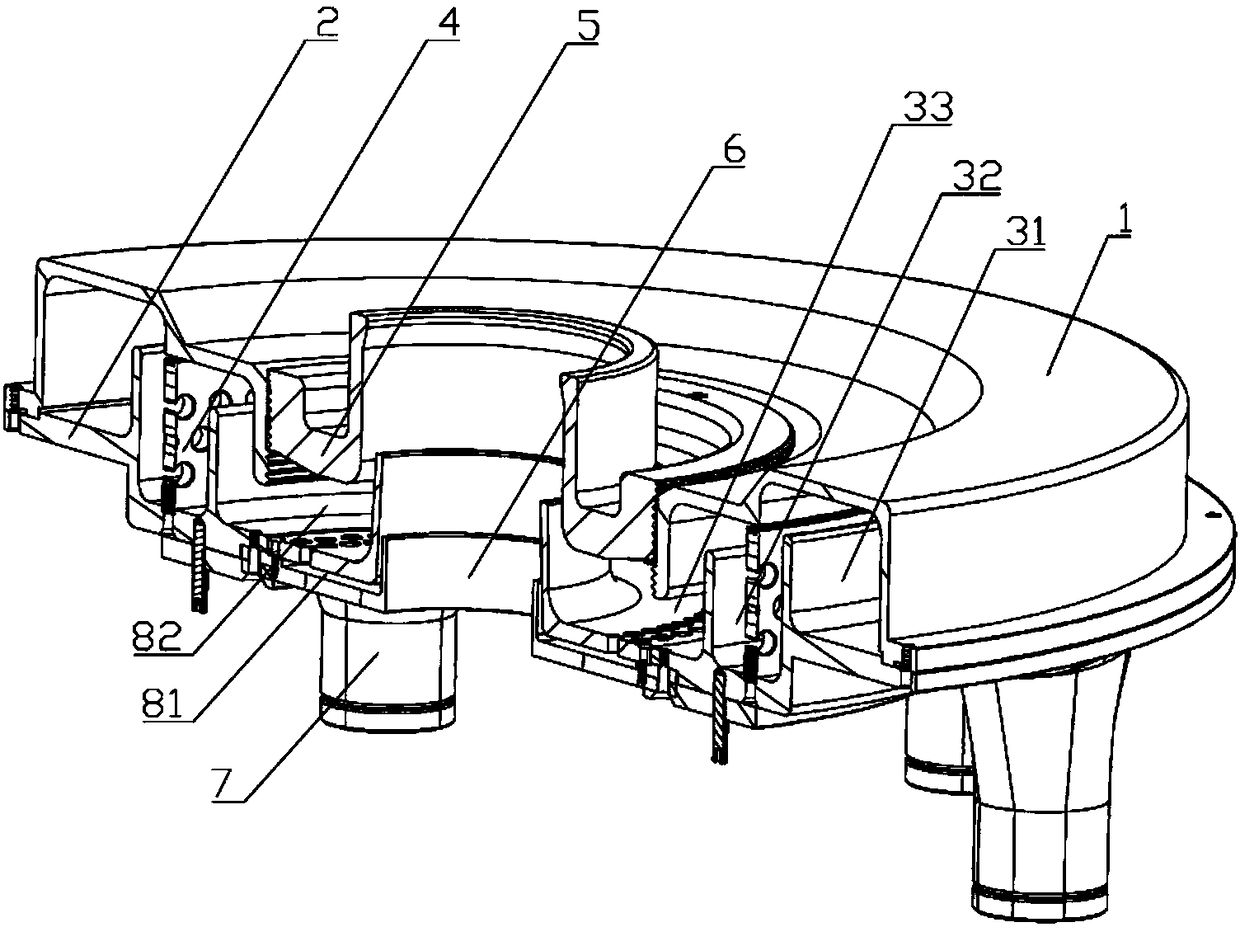

[0025] Such as Figure 1-3 As shown, a cooling device for film blowing equipment includes an air supply base 90, an air ring, and six air supply pipes 10. In the center of the air supply base 90, an upwardly facing air supply inlet 91 is provided, and the air supply inlet 91 is provided to the air supply through a flow diversion mechanism. The inner cavity of the air base supplies annular air flow, and the air supply pipe 10 is evenly arranged around the air supply base 90 and connected to the inner cavity of the air supply base and the annular main air duct 3;

[0026] Such as figure 2 As shown, the flow distribution mechanism includes a conical platform 93 collinear with the axis of the air supply inlet 91, an annular splitter plate 92, and an annular baffle 94, and the tip of the conical platform 93 on the inner cavity top wall of the air supply base 90 is downward. Pointing to the center of the air supply inlet 91, distribution holes are evenly arranged on the annular sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com