A temperature control device for graphene production

A control device, graphene technology, applied in graphene, temperature control by electric means, auxiliary controller with auxiliary heating device, etc., can solve the problems of high temperature control cost and inability to handle graphene temperature control, etc. Achieve the effect of saving power resources, facilitating production mode and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

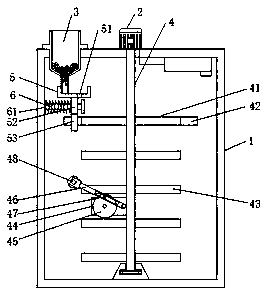

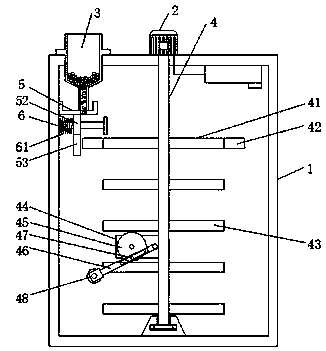

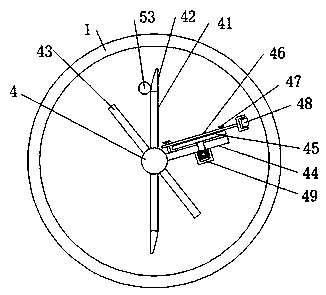

[0029] refer to Figure 1-4 , a graphene production temperature control device, including a device body 1, also includes

[0030] Graphene production drive mechanism, temperature regulation mechanism and feed control mechanism;

[0031] The graphene production drive mechanism located in the middle of the device body 1 includes an active vertical bar 4 and a first drive module 2 that drives the active vertical bar 4 to rotate, and horizontally arranged power drives are sequentially installed along the active vertical bar 4 from high to low. Driving rod 41 and evacuation rod 43, wherein there are multiple groups of evacuation rods 43, and the temperature control mechanism is arranged between the evacuation rods 43 of two adjacent groups;

[0032] The temperature control mechanism includes a fixed plate 44 welded on the active vertical bar 4, and one side of the fixed plate 44 is rotatably equipped with an active turntable 45 and a driven turnrod 46, and one side edge of the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com