A kind of aluminum veneer veneer thermal insulation integrated board and manufacturing method thereof

An aluminum veneer and thermal insulation board technology, which is applied in the field of building materials, can solve problems such as complex fire-proof thermal insulation structures, and achieve the effects of avoiding over-burning at welding places, high installation efficiency, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

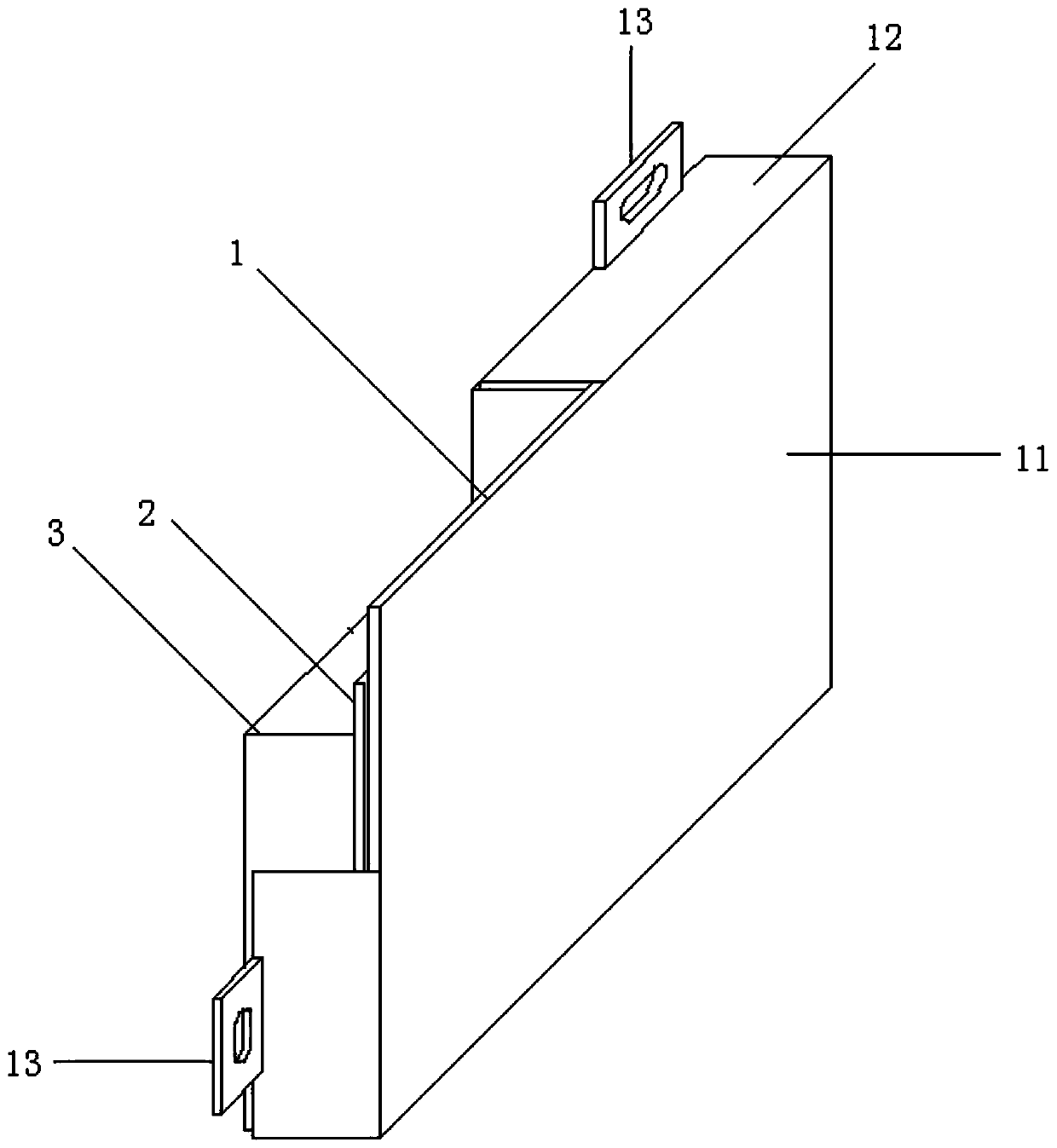

[0032] like Figure 1-2 As shown, an embodiment of an integrated panel with aluminum veneer decoration and heat preservation designed by the present invention, this embodiment is designed by taking an integrated panel with a size of 600x400mm as an example. It is composed of an aluminum veneer frame 1 and an insulating layer 3, and the two are connected by a fireproof transition bonding layer 2. The insulation layer 3 is selected from one of XPS board, EPS board, PU board, foam glass, rock wool or VIP board, and the fireproof transition bonding layer 2 is composed of cement, aggregate and high molecular polymer.

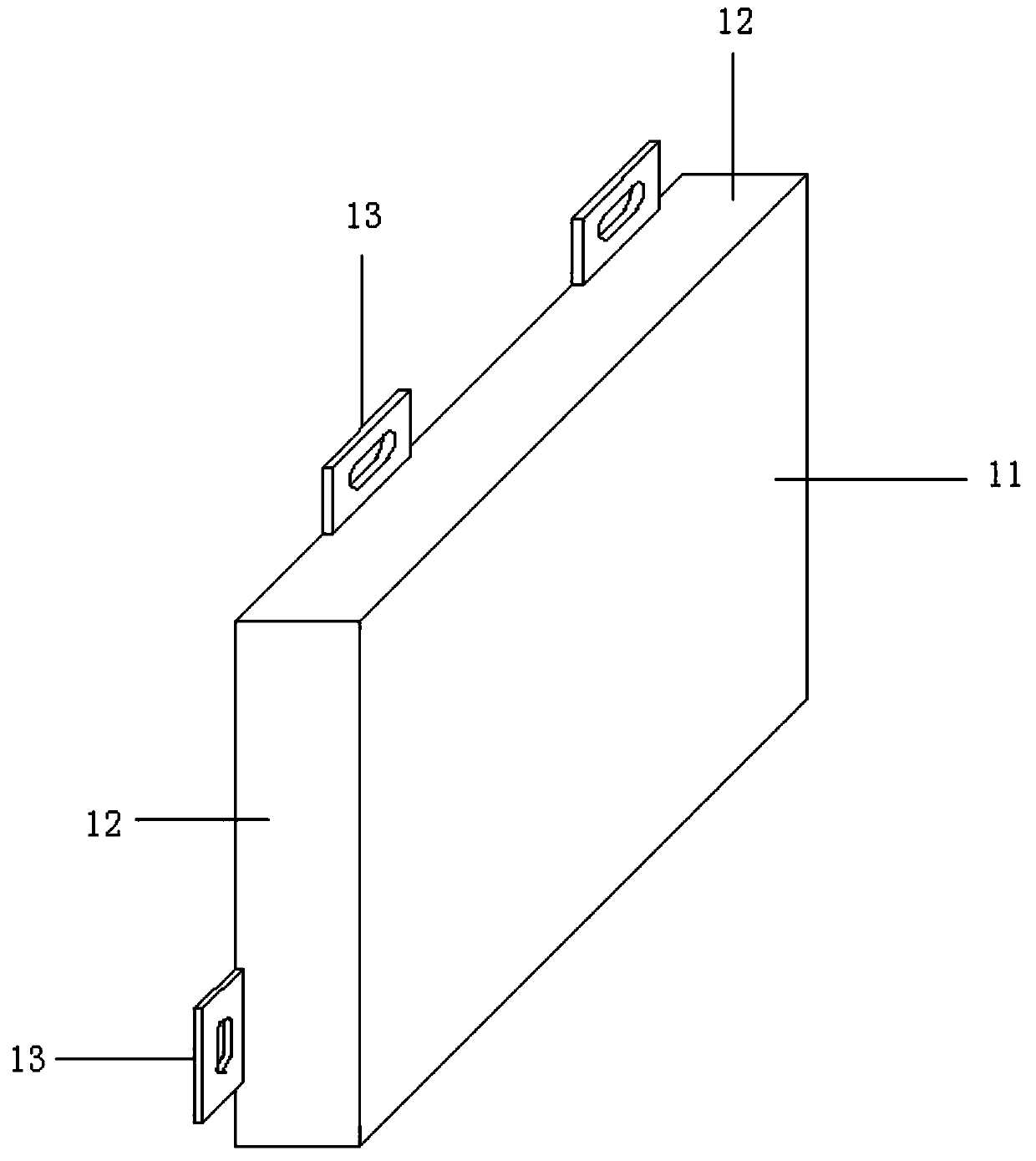

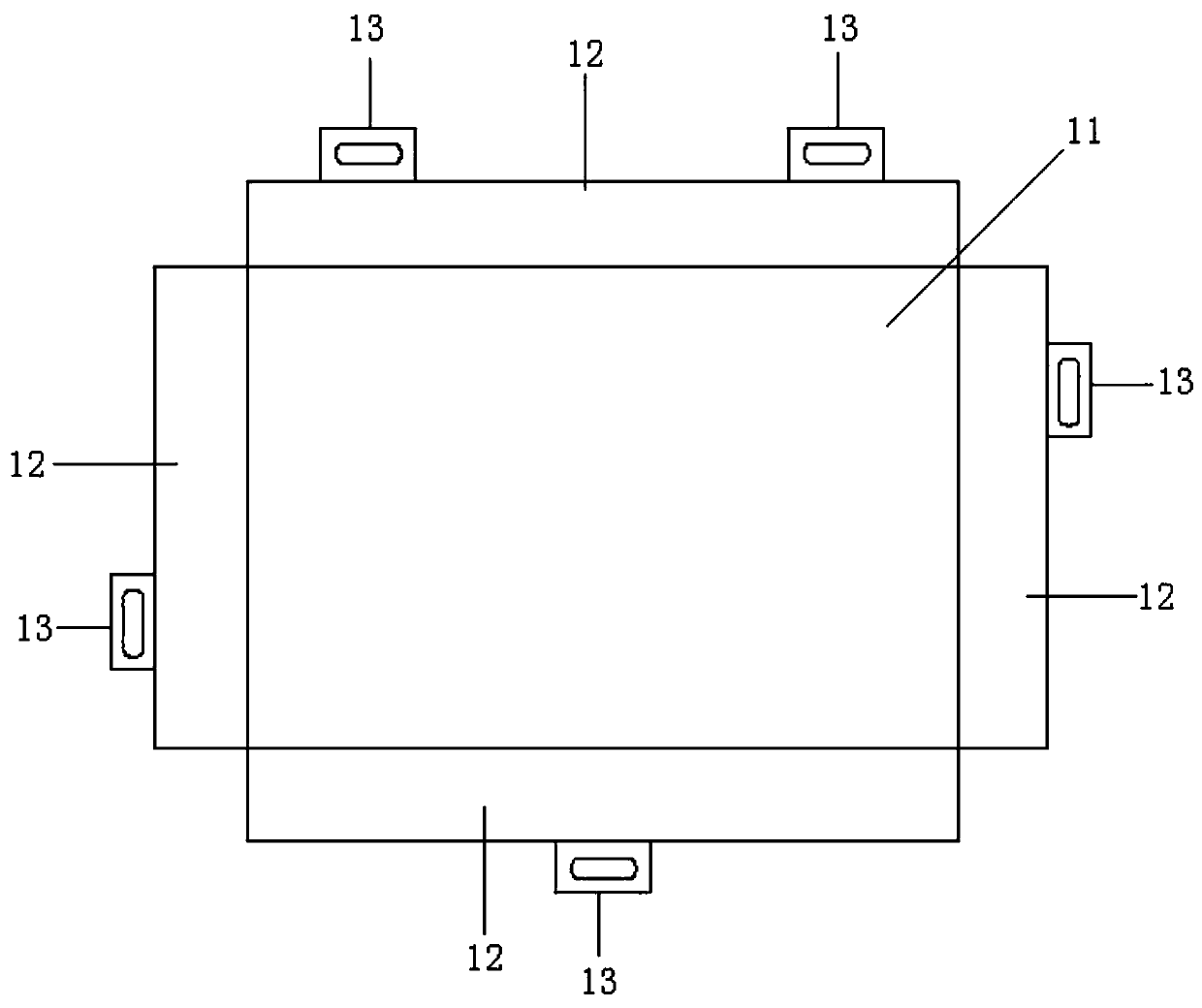

[0033] The aluminum veneer frame 1 is formed by cutting and stamping an aluminum plate, and its unfolded shape is as follows: image 3 As shown, the aluminum veneer frame 1 includes three parts: a panel 11 , a folded edge 12 and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com