Five-axis CNC cutting removal simulation method based on entity subdivision

A simulation method and solid technology, applied in instruments, computer control, simulators, etc., can solve the problems of low simulation operation efficiency, complex three-dimensional intersection calculation, and arbitrary rotation that does not support the view direction, and achieve high simulation operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

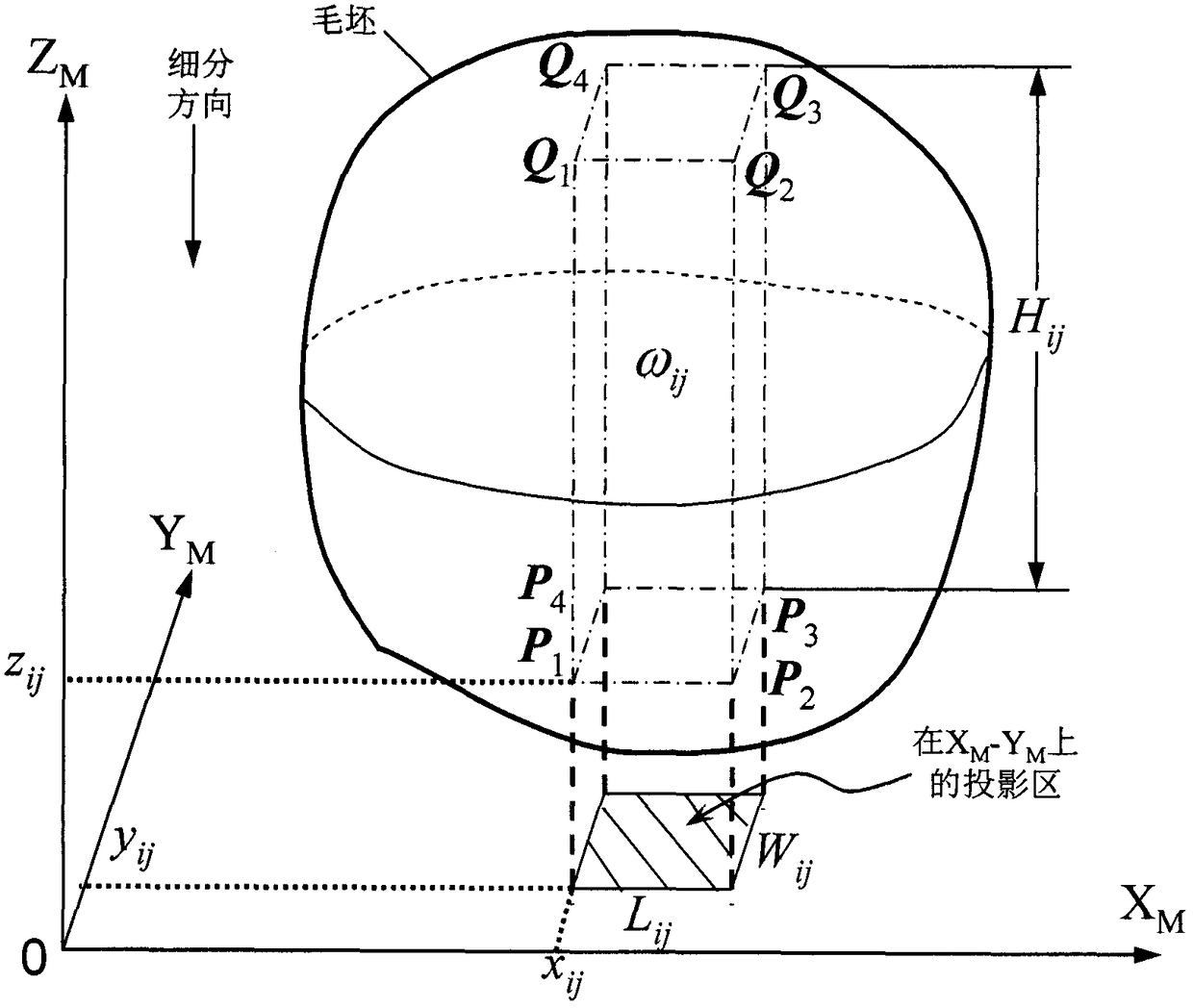

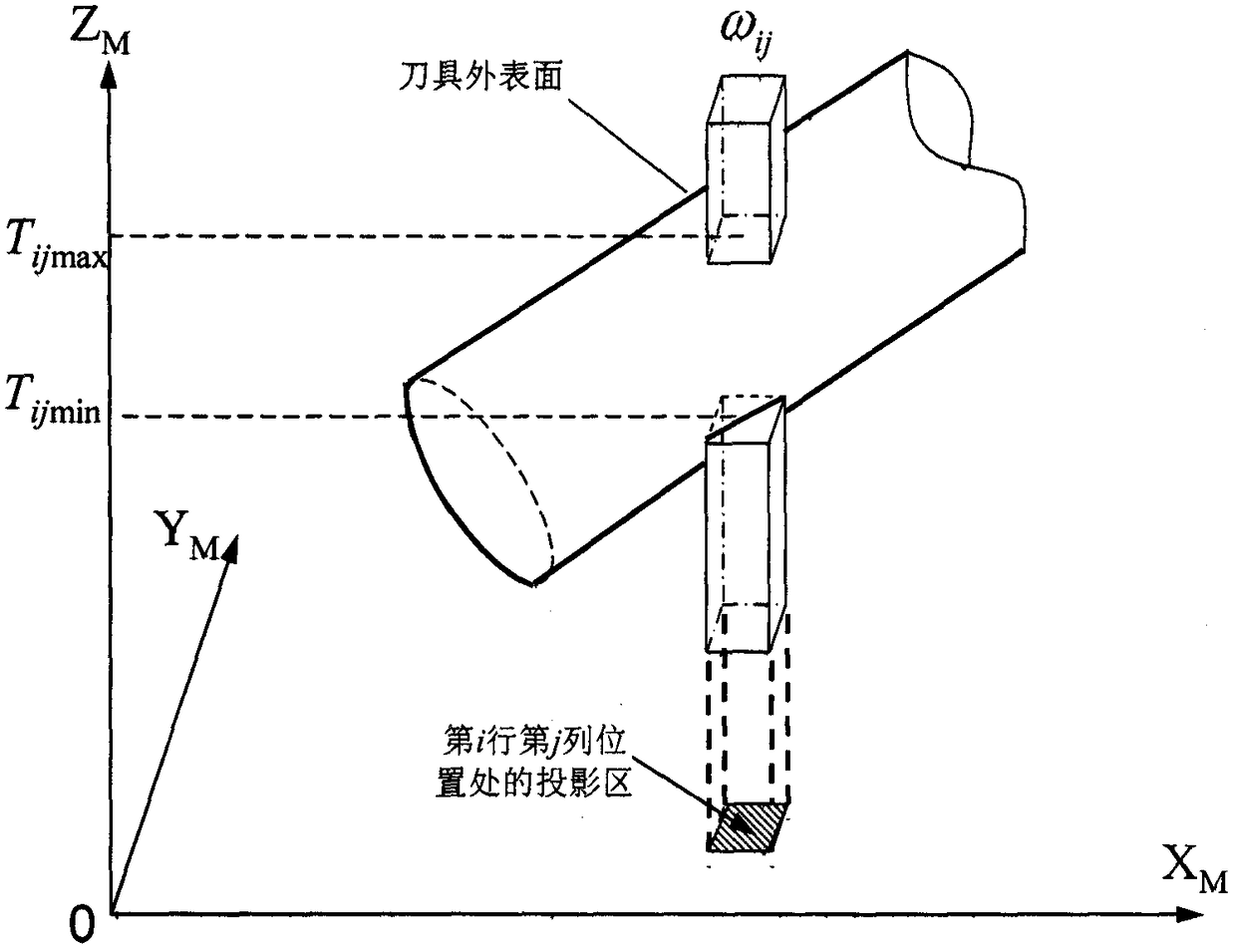

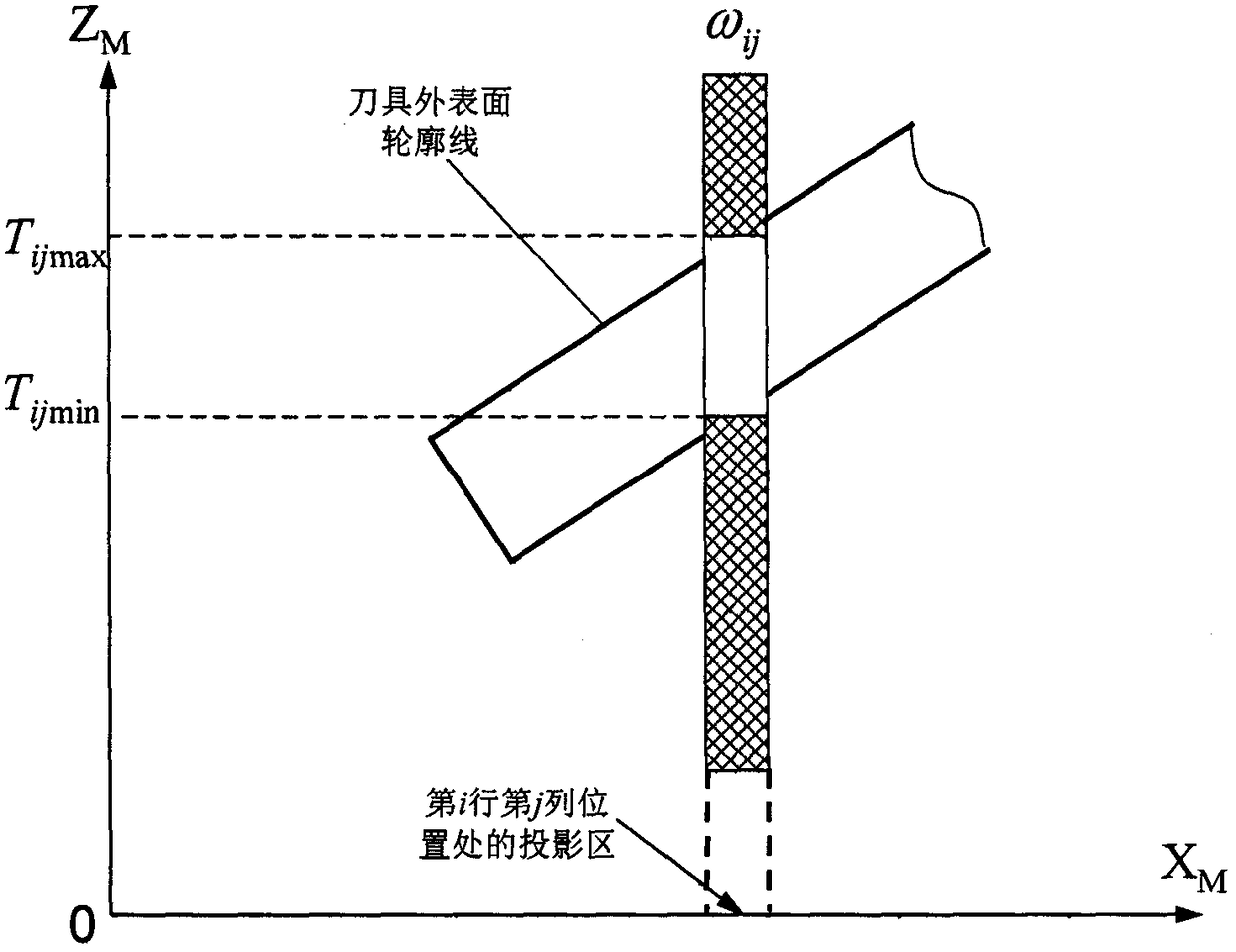

[0011] (1) First, subdivide the entity of the workpiece blank. Subdivision principle and idea: when the workpiece blank is clamped on the machine table, all points on the workpiece blank will be obtained in the coordinate system X of the machine tool. M -Y M -Z M coordinates below. Assume that along the five-axis CNC machine tool Z M If a light source shines on the workpiece blank in the negative direction of the axis, the workpiece blank will be divided into a positive surface and a negative surface, which are respectively defined as the top surface and the bottom surface. If the illuminating light source is subdivided into a quadrilateral grid, the workpiece blank will be solidly subdivided into several quadrangular prisms. The edges of all quadrangular prisms are parallel, and the upper and lower surfaces are respectively located on the top and bottom surfaces. According to the above subdivision principle, the subdivision of the blank entity is realized, and all subdivi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap