Busway for pouring and production method thereof

A production method and technology for bus ducts, which are applied in the direction of fully enclosed busbar devices, etc., can solve the problems of lack of preventing concrete penetration, insufficient concrete affinity, and being easily damaged by the outside world, so as to avoid the diffusion of current sound, ensure insulation, and improve The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

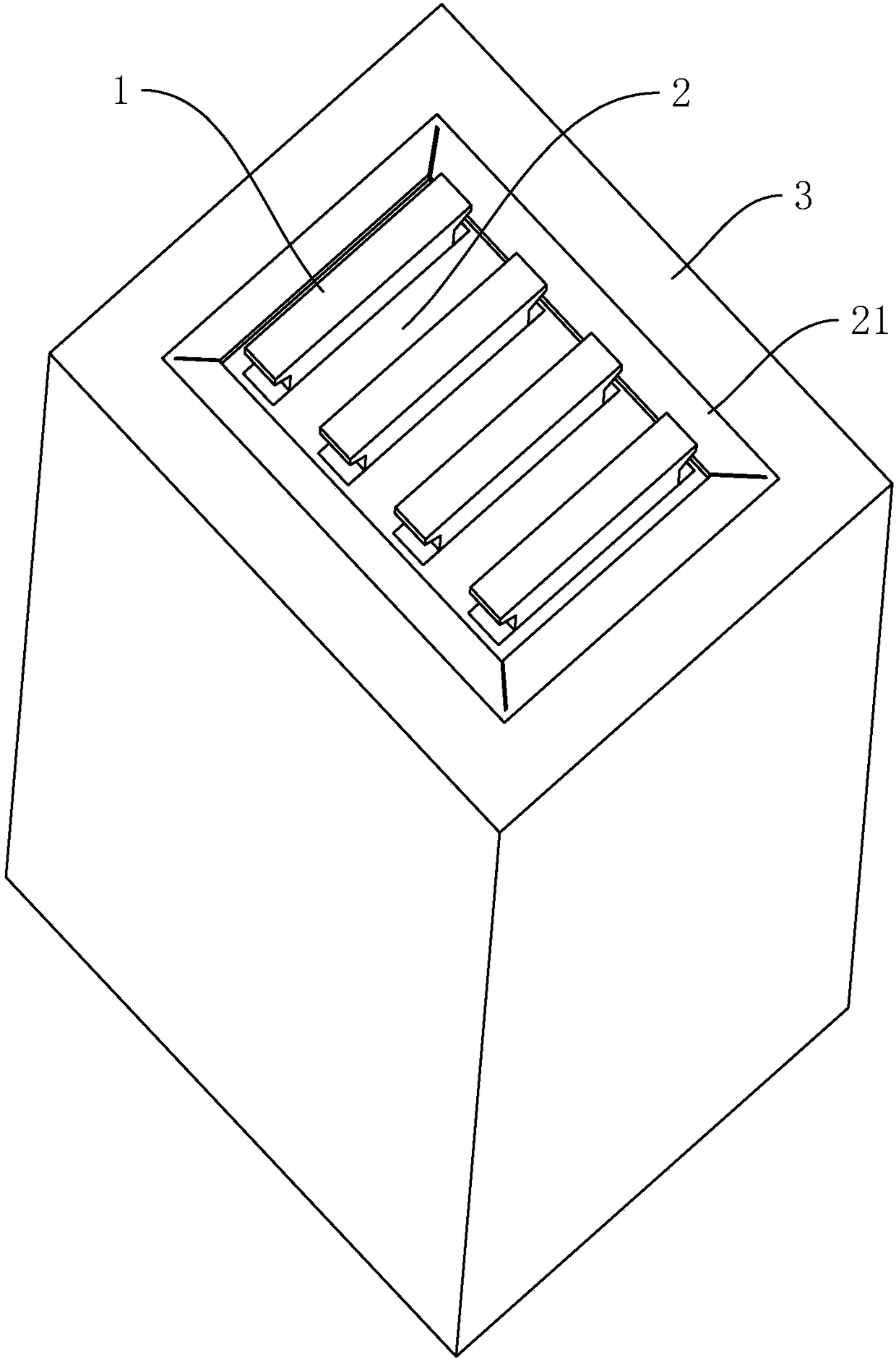

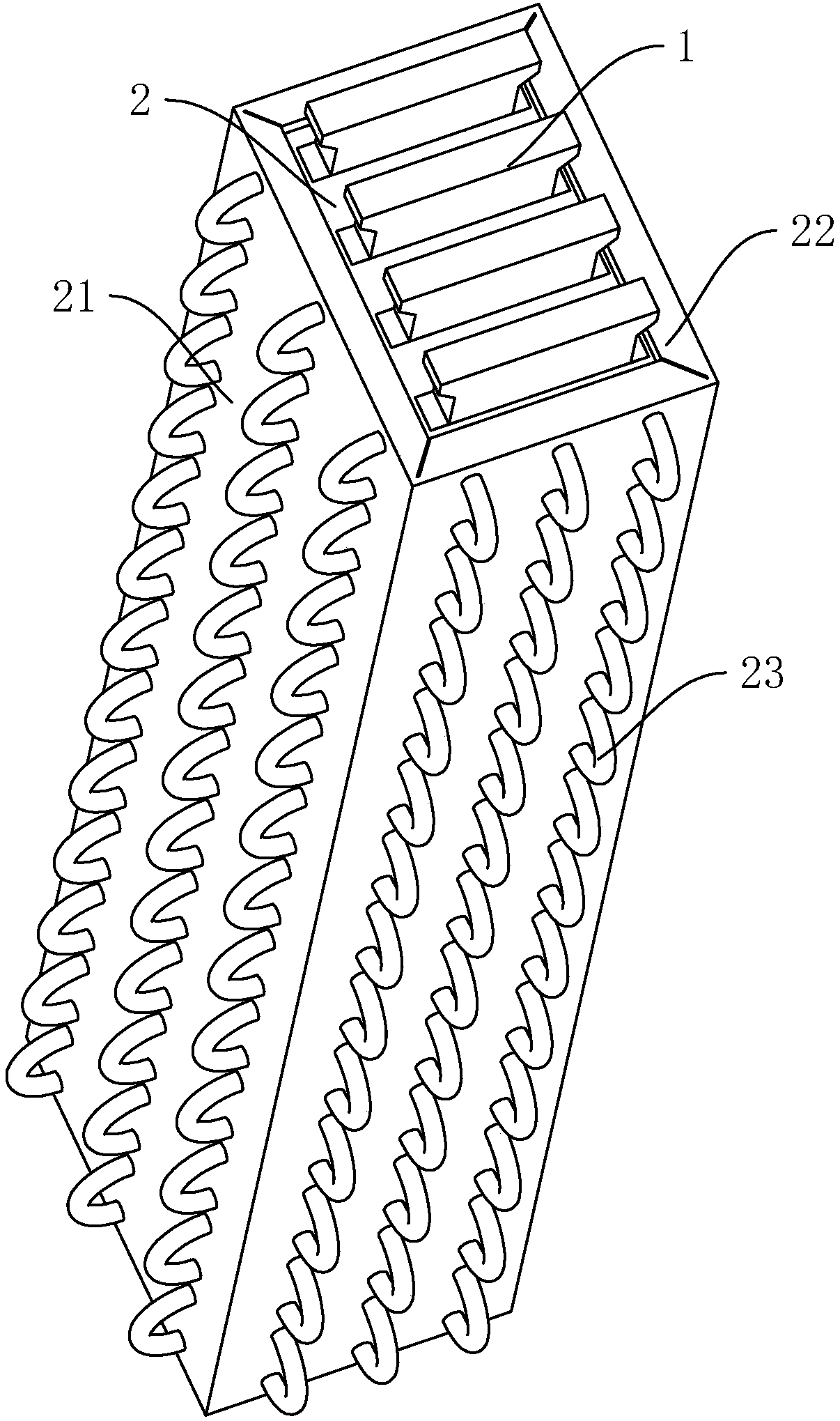

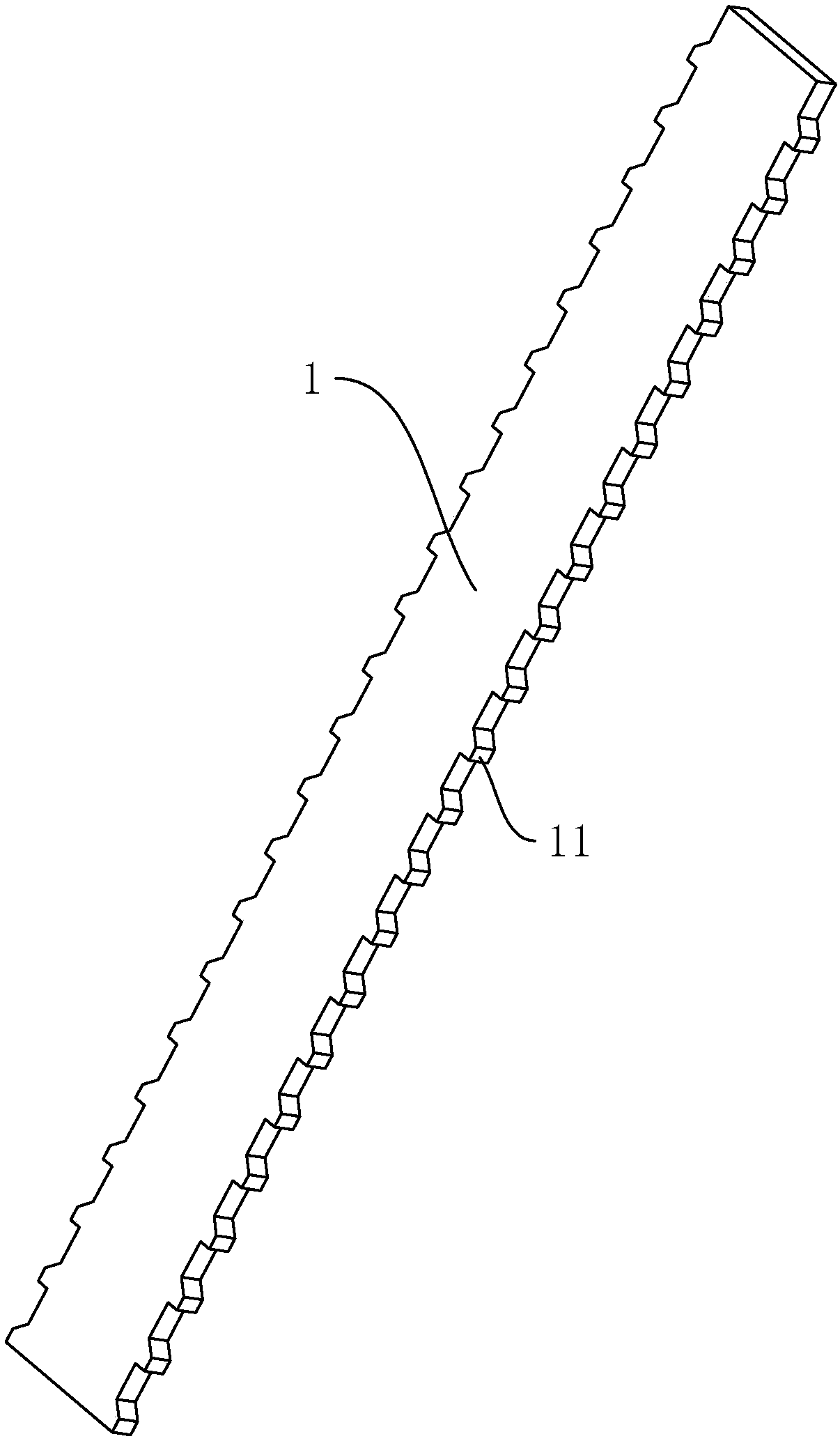

[0047] Embodiment 1: The bus duct for pouring, such as figure 1 , figure 2 As shown, it includes a busbar copper conductor 1, and an epoxy resin body 2, and also includes a concrete shell 3. There are at least four busbar copper conductors 1. In this embodiment, the number of busbar copper conductors 1 is four, and the busbar copper conductor 1 wears Set in the epoxy resin body 2, the epoxy resin body 2 is set with a metal spacer 21, and the concrete shell 3 is wrapped in the metal spacer 21.

[0048] The busway provided in this embodiment has the following advantages: 1. A plurality of busbar copper conductors 1 use epoxy resin body 2 as isolation support, thereby utilizing the excellent insulation performance of epoxy resin body 2 to effectively prevent adjacent busbar copper conductors from 1, and at the same time, use the epoxy resin body 2 to wrap the copper conductor of the busbar, on the one hand, avoid the leakage phenomenon of the busway, and on the other hand, impr...

Embodiment 2

[0053] Embodiment two: the production method of bus duct for pouring, such as Figure 4 , Figure 5 , Image 6 shown, including the following steps:

[0054] A. Prepare the mould: use mold steel to cast the upper mold 41 and the lower mold 42, and use a slotting machine to open the slot 43 on the opposite surface of the upper mold 41 and the lower mold 42. The depth of the slot 43 is equal to the extension of the busbar copper conductor 1 Out of the length of the epoxy resin body 2, a slotting machine is used to open a resin injection groove 44 and a concrete injection groove 45 above the upper mold 41; a cutting machine is used to cut a stainless steel plate, and a bending machine is used to bend it to form two pieces with a cross-sectional shape of L Shaped plate 46; Die steel is used as the material of the upper die 41 and the lower die 42, thereby realizing the sustainable use of the upper die 41 and the lower die 42, thereby reducing production costs; the upper die 41 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com