A method of preparing natural gas at a gas pressure reduction stations to produce liquid natural gas (LNG)

A technology for liquid natural gas and natural gas, applied in gas fuel, gas processing, separation methods, etc., can solve problems such as high capital and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

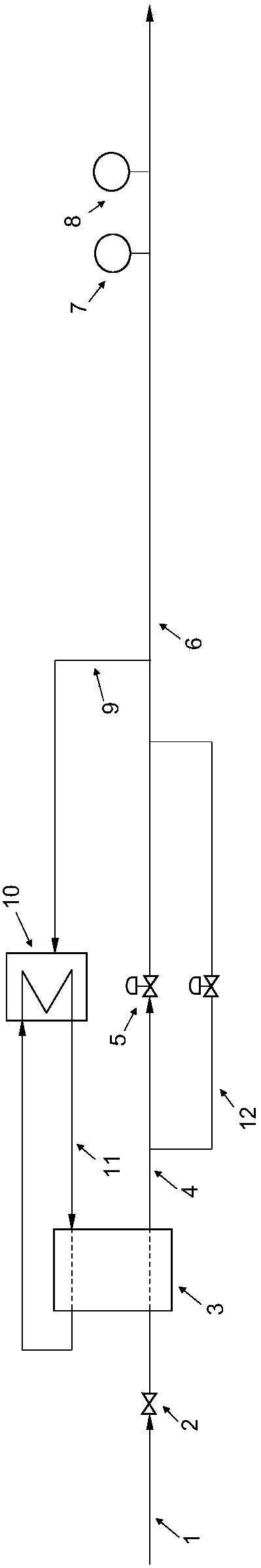

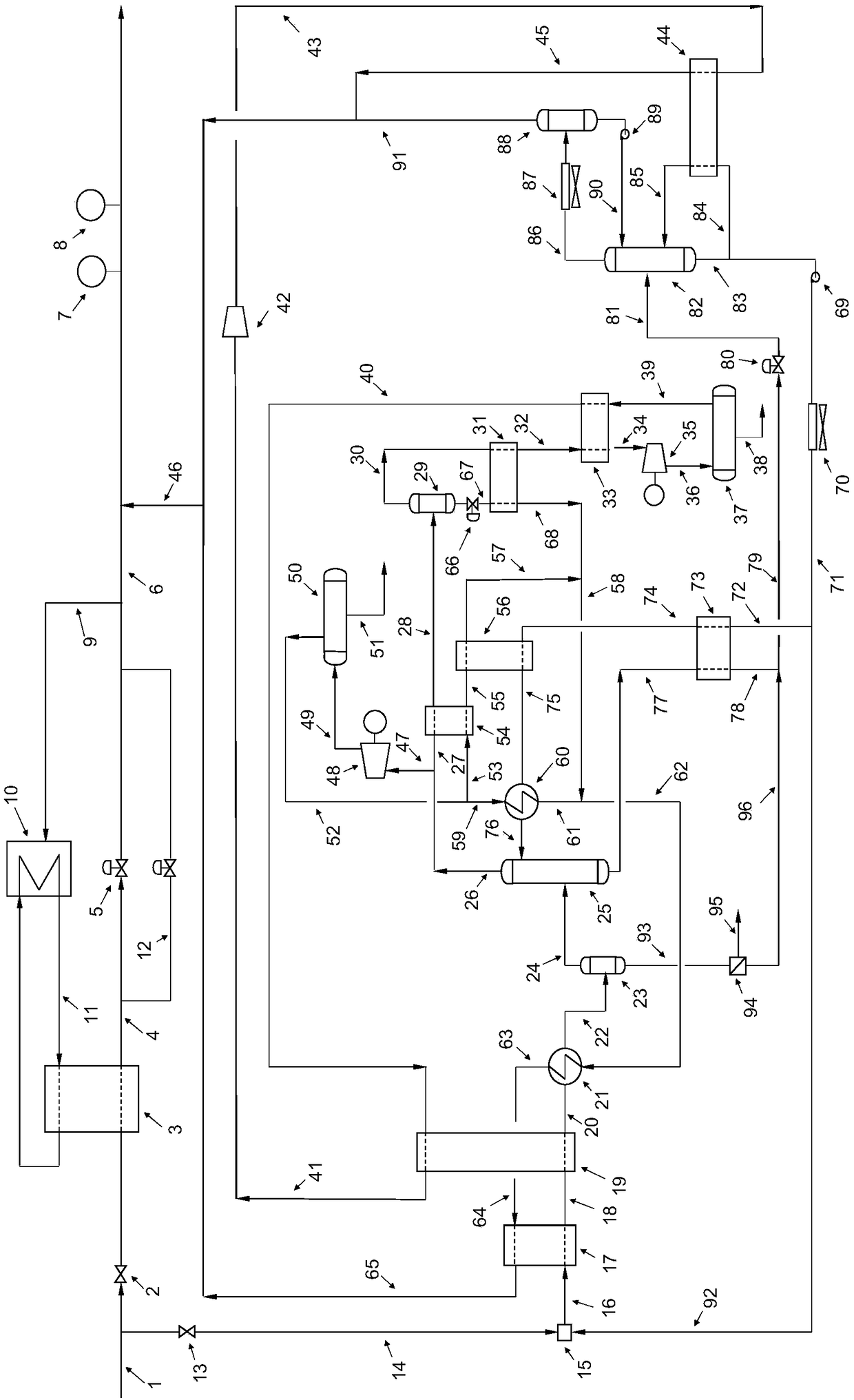

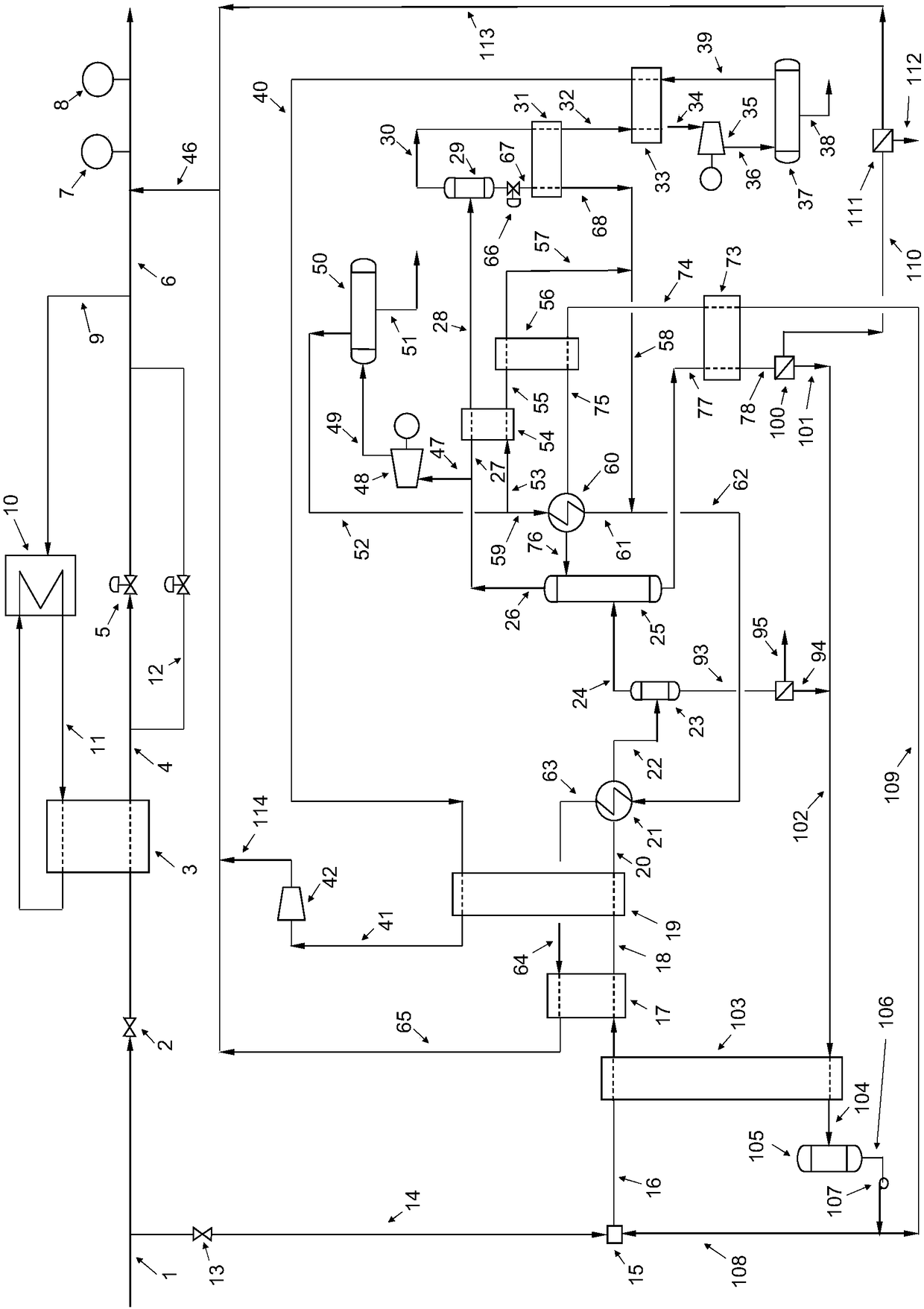

[0064] will now refer to Figures 1 to 3 Describe the method.

[0065] In the method of the present invention, cooling energy is provided by recovering pressure energy that is currently wasted in the depressurization station. The recovered energy also allows the methanol to be refrigerated at much cooler temperatures and thus with greater efficiency. For example, in the process of the present invention, the average refrigerated methanol temperature is -80°C.

[0066] The process was developed to prepare a natural gas stream at a gas decompression station for the production of LNG. Said method uses a different way of methane expansion cycle, which has heretofore been used in commercial applications known as decompression stations. The system described herein utilizes the gas flow delivered to the zone distribution pipeline at the depressurization station to provide an improved method of producing LNG at the depressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com