Device and method for wavefront analysis

A wavefront, to-be-analyzed technology, used in measurement devices, photolithographic process exposure devices, lens position determination, etc., can solve problems such as high spatial frequency, high fringe density, interference pattern analysis, etc. The effect of high speed and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

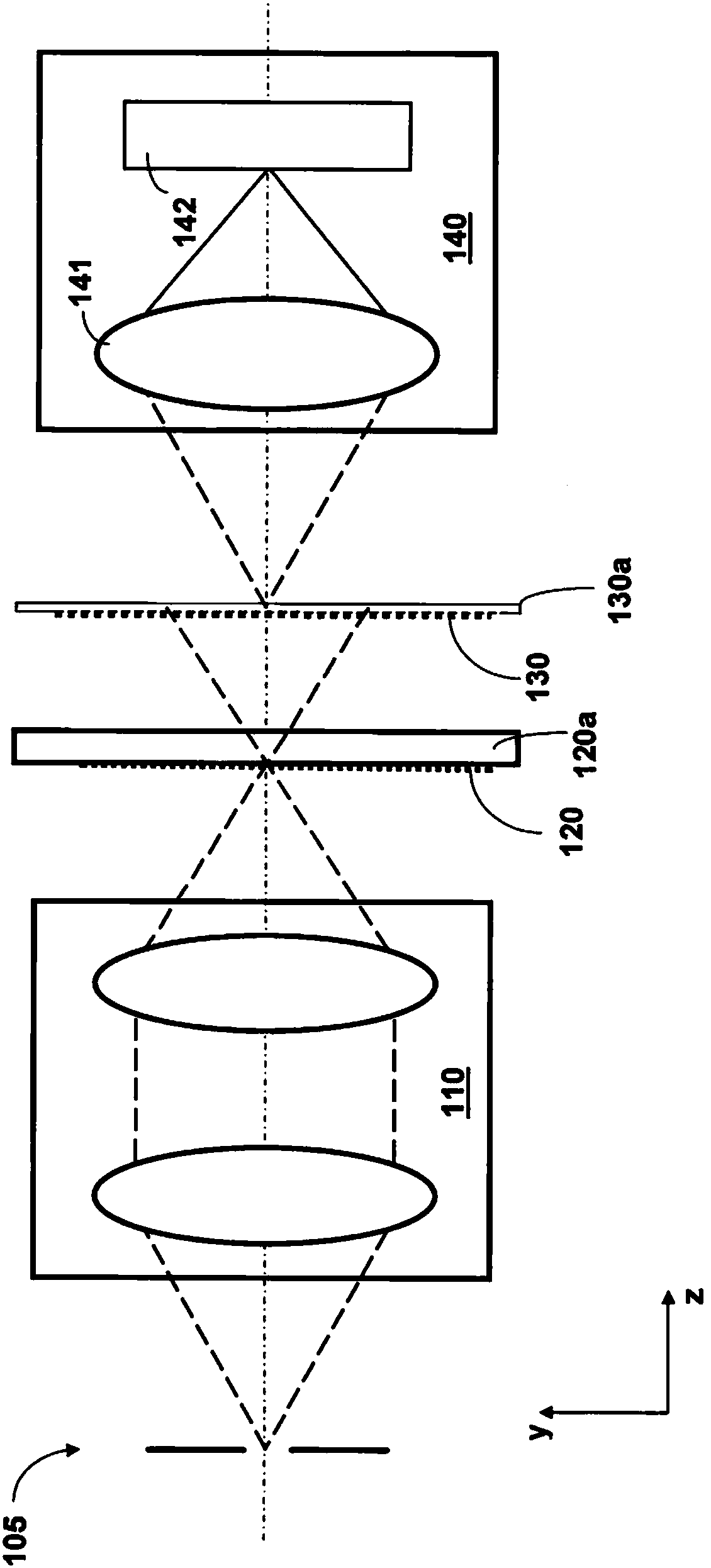

[0051] figure 1 A schematic diagram of a possible setup of a device according to the invention for wavefront detection is first shown.

[0052] exist figure 1 In , the wavefront effect marks the tested imaging optical unit as "110", which can also be any subsystem of the illumination device or the projection lens of the microlithography projection exposure device. In order to examine the wavefront effect of the imaging optical unit 110 or to analyze the wavefront of light waves passing through the imaging optical unit 110, according to figure 1 The configuration has an illumination mask 105 in the form of a perforated mask through which light from a light source (not shown) enters the imaging optical unit 110 and is incident on is the z direction) and is disposed on the first grating 120 downstream of the imaging optical unit 110 .

[0053] The first grating 120 has at least one first grating structure and is applied on a substrate designated "120a", the substrate 120a bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com