Electron emission electrode and process for production thereof

An electron emission and electrode technology, which is applied in the direction of electrode system manufacturing, cold cathode manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of troublesome, unobtainable electron emission electrode durability, etc., achieve high emission current, optimize manufacturing and Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] figure 1 A substrate composed of fragmented material, such as a silicon wafer, is shown. The base body 1 , which forms the electron-emitting electrode 2 , is processed according to the invention, which is explained in greater detail below with reference to partial regions of the base body 1 .

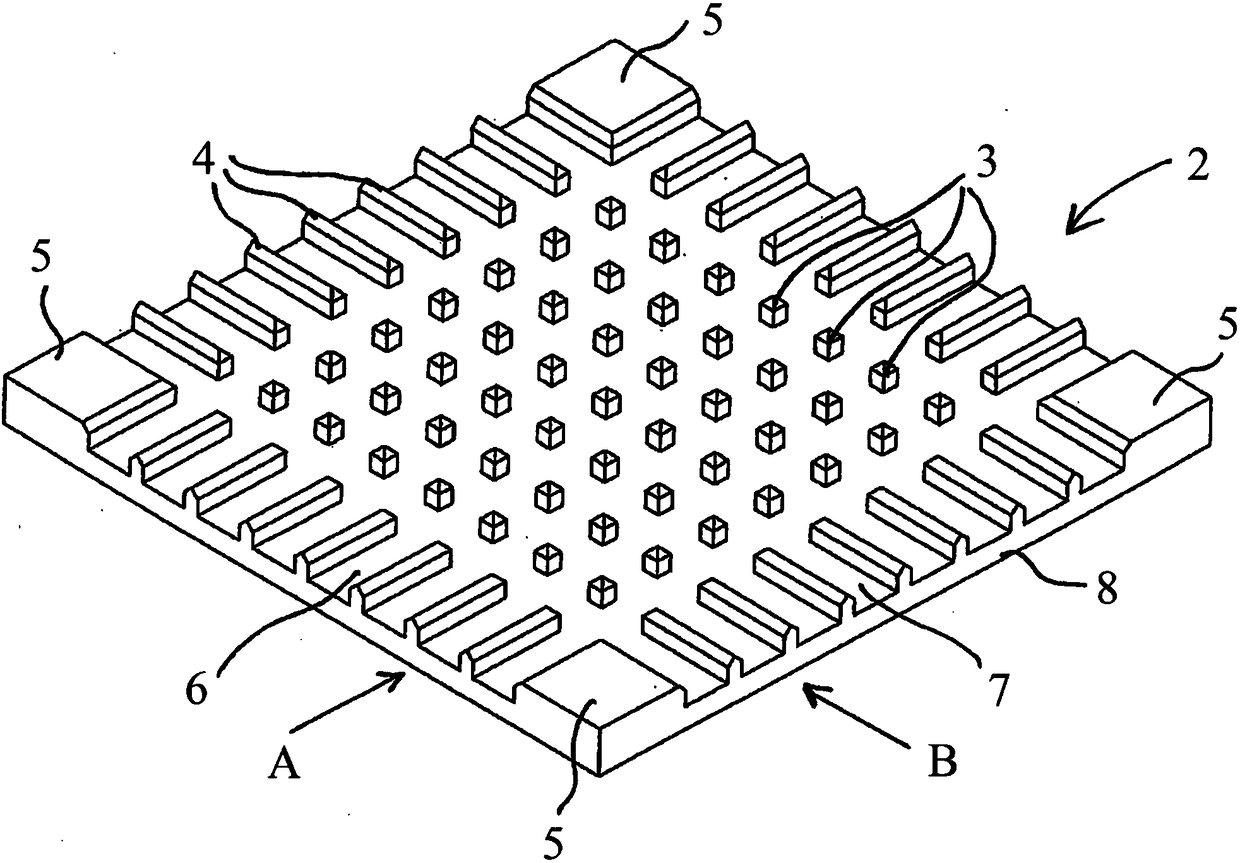

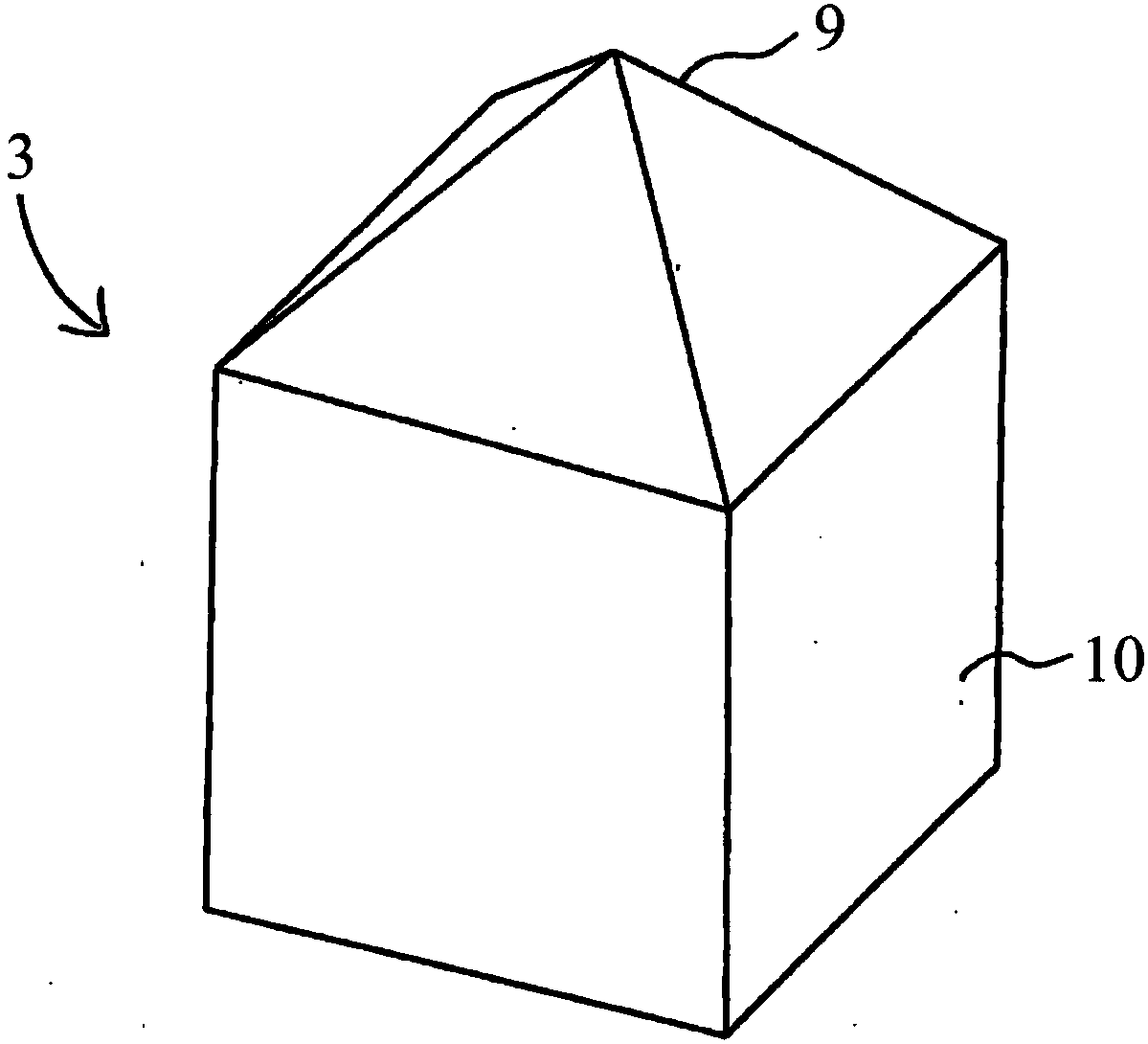

[0043] figure 2 Shown is an enlarged view of a local area in which a substrate 1 has been subjected to surface processing, by which the local area is formed as an electron emission electrode 2 having a plurality of emission tips. exist figure 2 Visible in FIG. 1 is the arrangement of a plurality of point-shaped elevations 3 which contain the emission tips of the electron emission electrodes 2 . In the edge region there are a plurality of linear elevations 4 which surround the matrix-shaped arrangement of pointed elevations 3 . In the respective end regions of the electron emission electrode 2 there is a cuboidal elevation 5 which can serve as a base region for the electron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com