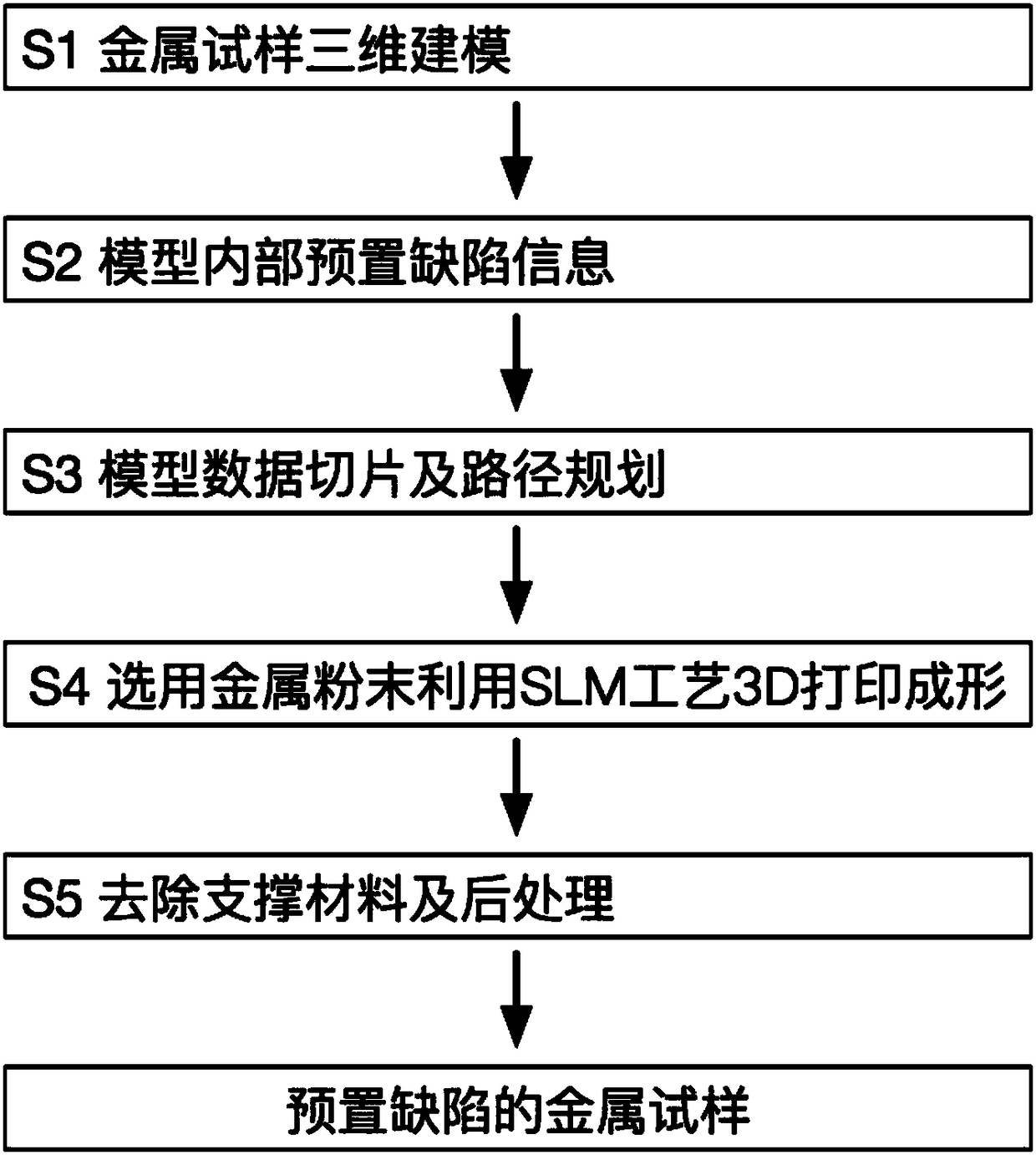

Metal sample 3D printing forming method with defect presetting process

A metal sample, 3D printing technology, applied in the direction of improving process efficiency, improving energy efficiency, additive manufacturing, etc., can solve the problems of material organization, performance change, and inability to measure mechanical properties, and achieves improved sample preparation accuracy, Simplify the difficulty of sample preparation and ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0021] This case is to prepare a TC4 titanium alloy sample 10 with 3 pore defects 6 and 1 crack 9. The size of the sample is 20*20*20mm, the diameter of the pore is 0.05mm~0.1mm, and the crack length is 8mm. Its specific preparation process is as follows:

[0022] Step 1, utilize three-dimensional modeling software, such as Pro-E, UG, Solidworks etc. to carry out the modeling of TC4 titanium alloy sample 10;

[0023] Step 2, adding the required size and position of defects 6 and 9 to the sample model to form a three-dimensional model with defects;

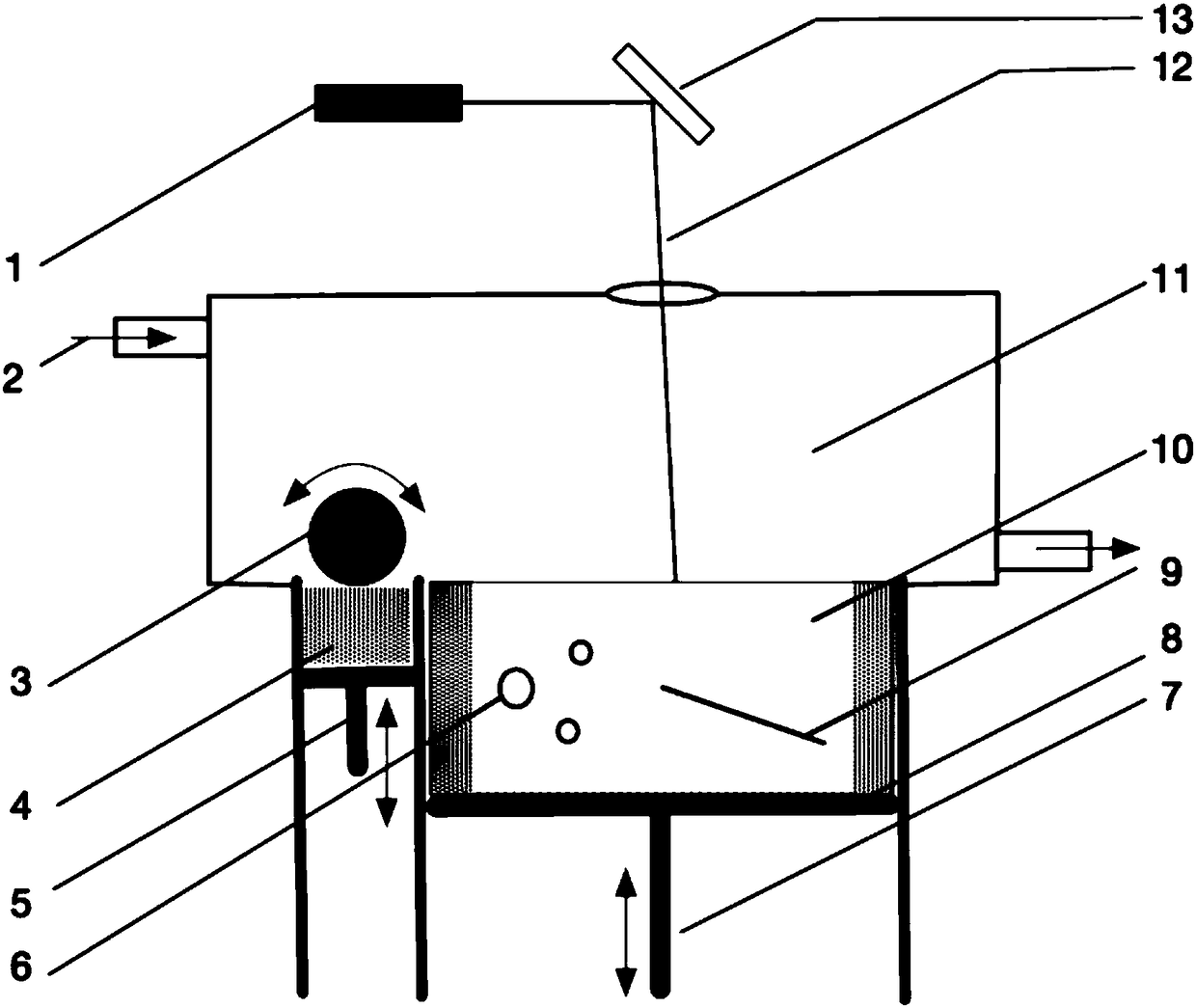

[0024] Step 3. Select a laser selective melting (SLM) 3D printing device of appropriate size, use the software supporting the printer to slice the 3D model and plan the printing path, and then set the printing parameters;

[0025] Step 4: Place the substrate 8 on the lifting platform 7 of the forming platform, pass through the protective gas 2 , and the laser beam 12 generated by the laser 1 enters the forming cavity 11 after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com