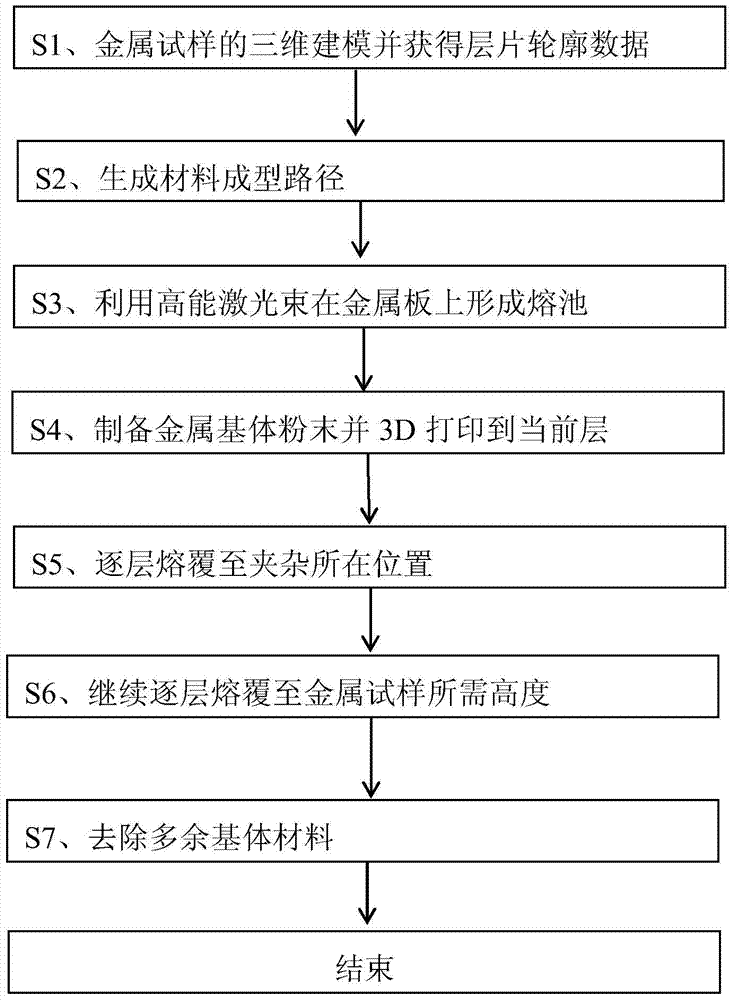

A 3D printing method for metal samples containing built-in inclusions

A metal sample and 3D printing technology, which is applied in the field of material forming and rapid prototyping of powder materials, can solve problems such as inclusions, achieve the effect of improving precision and accuracy, and simplifying the difficulty of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

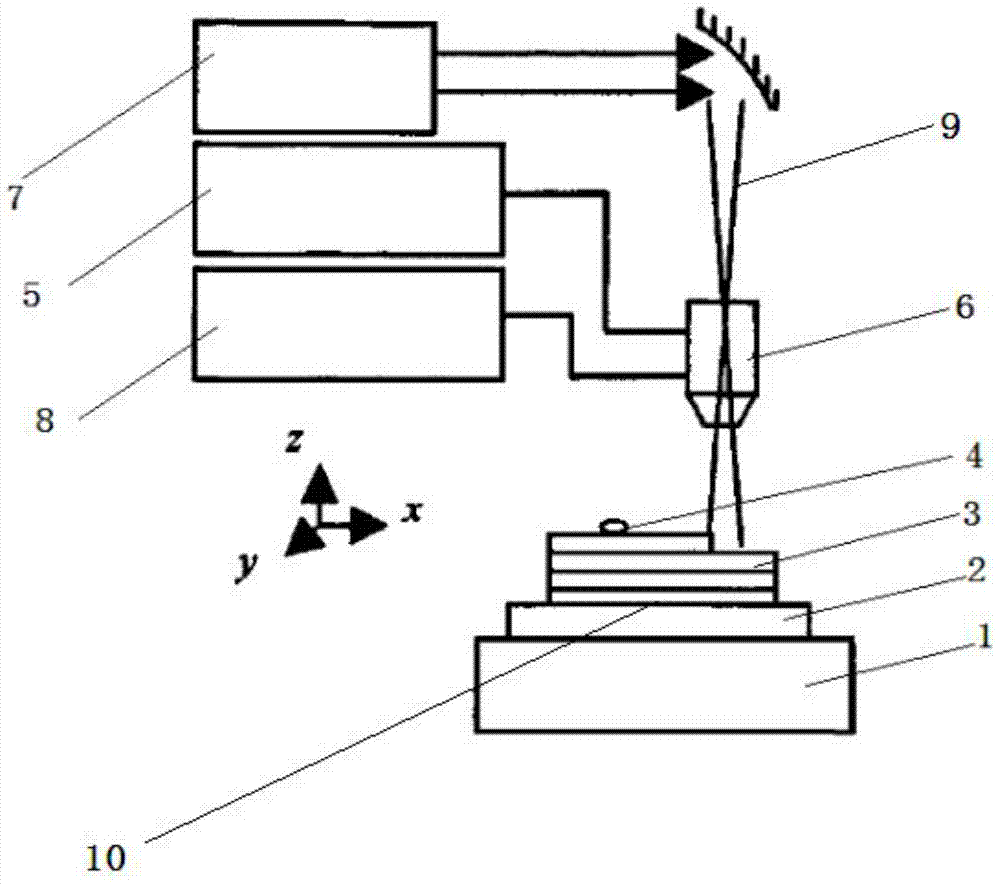

[0032] This embodiment is to prepare a 304L stainless steel cylindrical sample 3 containing a spherical alumina inclusion 4 in the center. The specific size of the stainless steel cylindrical sample 3 is φ10×15mm, and the maximum diameter of the spherical alumina inclusion 4 is 0.5mm. The specific implementation The process is as follows:

[0033] Step 1, using a three-dimensional modeling system such as: UG, Pro / E to model the 304L stainless steel cylindrical sample 3 and perform layered processing to obtain layer profile data;

[0034] Step 2. Input the ply profile data of the cylindrical sample into the laser cladding forming equipment and automatically generate the material forming path according to the obtained information;

[0035] Step 3: Prepare a 304L stainless steel plate 2 with a suitable size by laser cladding forming method and place it on the workbench 1 of the laser cladding forming equipment, use the high-energy laser beam emitting device 7 to generate a high-e...

Embodiment 2

[0041] This embodiment is the preparation of a 7A85 aluminum alloy sample 3 containing a spherical manganese sulfide inclusion 4 in the center. The shape of the sample 3 is generally cylindrical and irregular. The maximum peripheral size of the 7A85 aluminum alloy sample 3 is φ12×24mm, and the diameter of the spherical alumina inclusion 4 is 0.1mm. The specific implementation process is as follows:

[0042] Step 1, using a three-dimensional modeling system such as UG and Pro / E to model the 7A85 aluminum alloy sample 3 and perform layered processing to obtain the layer profile data of the three-dimensional model;

[0043] Step 2: Input the layer profile data of 7A85 aluminum alloy sample 3 into the laser cladding forming equipment and automatically generate the material forming path according to the obtained information;

[0044] Step 3: Prepare a 7A85 aluminum alloy plate 2 with a suitable size by laser cladding forming method and place it on the workbench 1, use the high-ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com