Patents

Literature

34results about How to "Does not break continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

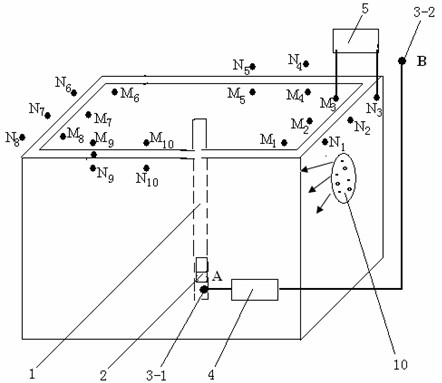

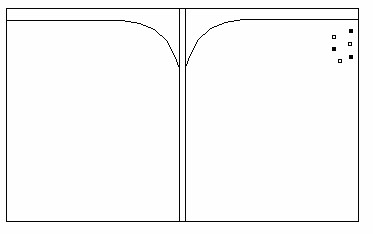

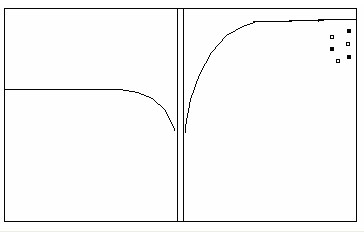

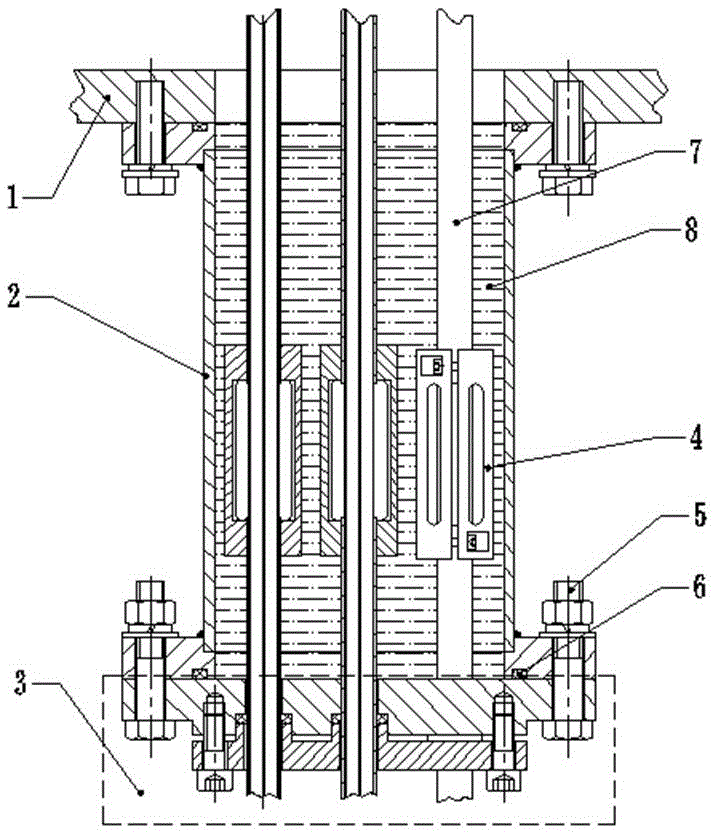

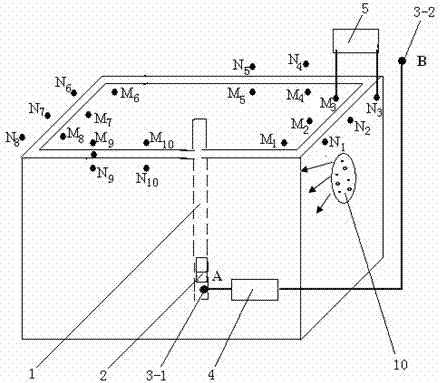

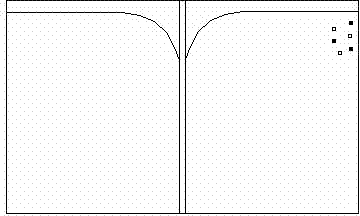

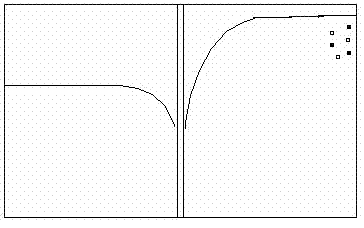

Method and device for monitoring seepage of underground diaphragm wall of foundation ditch of building

ActiveCN102691286ADoes not break continuityOmit mechanical testIn situ soil foundationSlurry wallMarking out

The invention relates to a method and device for monitoring the seepage of an underground diaphragm wall of a foundation ditch of a building. The method comprises the following steps of: (1) constructing a borehole at the center of the foundation ditch, arranging a power supply electrode A at the bottom of the borehole, and arranging another power supply electrode B at a place 7-10 times of the length of the foundation ditch away from the center of the foundation ditch; (2) arranging detection points on the ground surface along the underground diaphragm wall in a manner of surrounding the foundation ditch, and arranging a measuring electrode M and a measuring electrode N at each detection point along the direction vertical to the underground diaphragm wall; (3) marking out planar positions with abnormal formula (shown in a drawing); (4) marking out vertical elevations with the abnormal formula (shown in the drawing); and (5) obtaining positions corresponding to the planar positions with the abnormal formula obtained in the step (3) and the vertical elevations with the abnormal formula obtained in the step (4), thereby obtaining positions in seepage. The invention further relates to a device for monitoring the seepage of the underground diaphragm wall of the foundation ditch of the building. By using the method and device for monitoring the underground diaphragm wall of the foundation ditch of the building, the damage to an underground diaphragm wall body can be avoided, and the operation is very simple and convenient.

Owner:湖南继善高科技有限公司

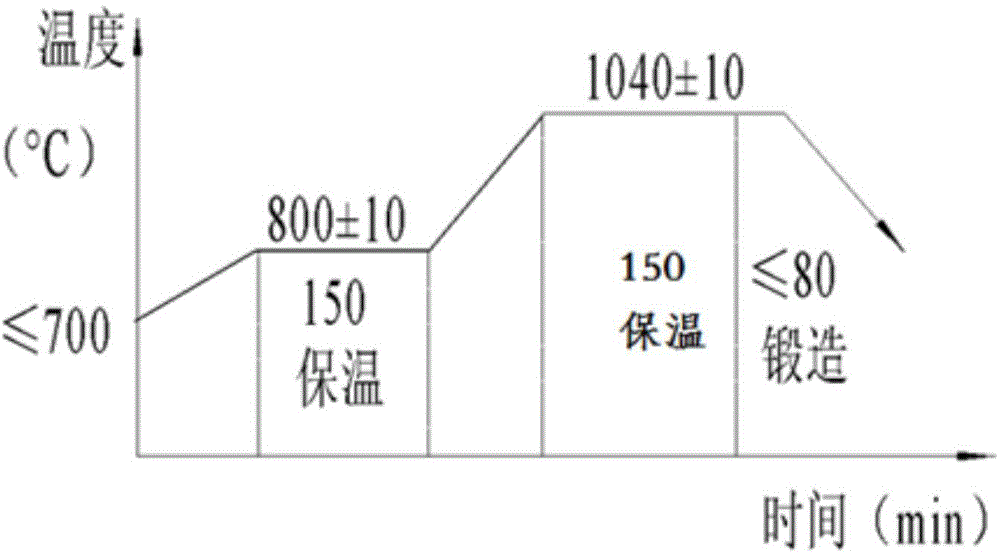

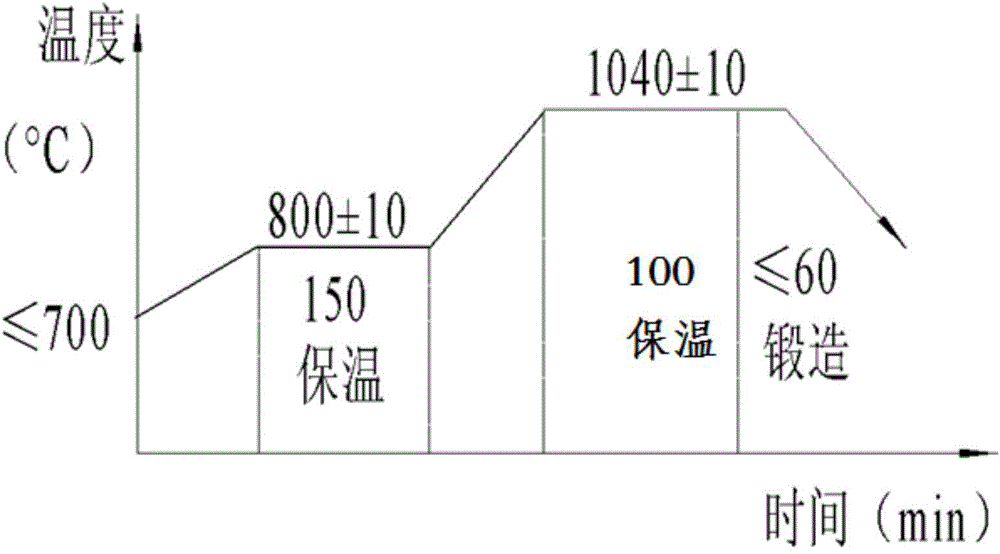

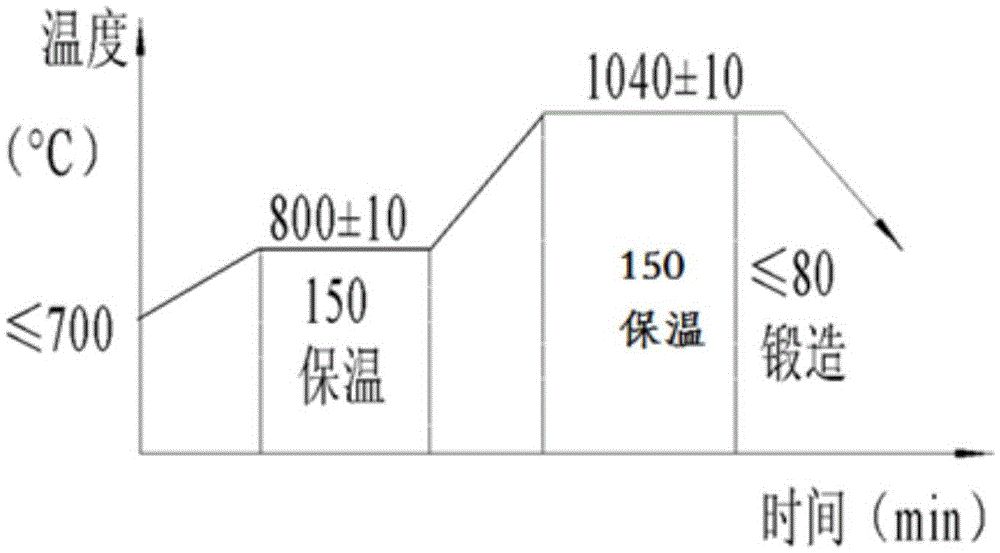

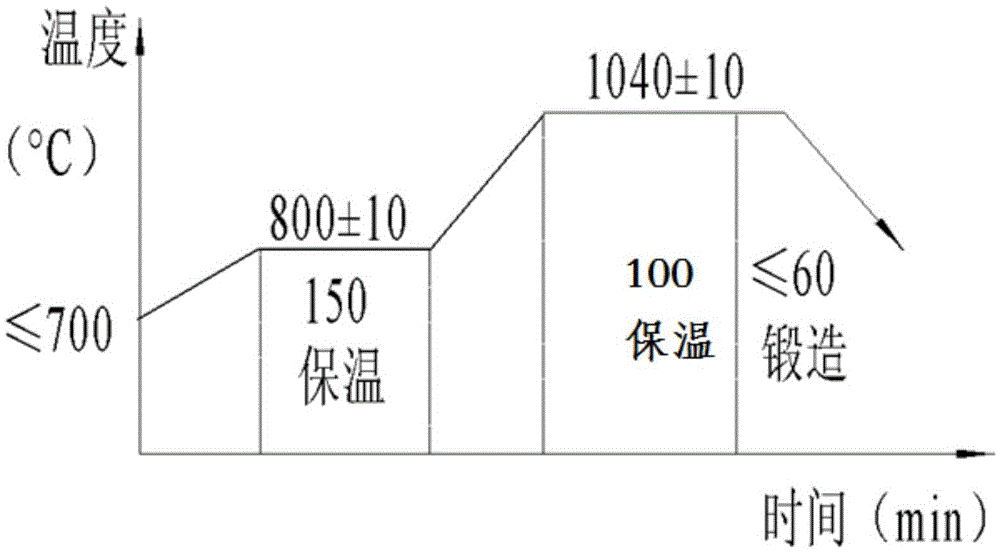

Grain refining efficient forging method of high-alloy ultrahigh-strength steel large-scale die-forged parts

ActiveCN104874712ADoes not break continuityImprove pass rateMetal-working apparatusAlloyUltimate tensile strength

The invention belongs to the technical field of forging and relates to a grain refining efficient forging method of high-alloy ultrahigh-strength steel large-scale die-forged parts. The method is used for machining large-scale die-forged parts such as an airplane landing gear and includes the steps of shearing billets, heating, manufacturing billets, heating and die forging. The method has the advantages that the grain refining efficient forging method of the high-alloy ultrahigh-strength steel large-scale die-forged parts is researched for the first time, the forged parts acquire 8-level grains while the production efficiency of the forged parts is 5-8 times of that of conventional forged part production, and noises during production is reduced by more than 30 decibel; the high thermoplasticity of high-alloy high-strength steel is combined with a fast forging machine and a large hydraulic machine, billet manufacturing and die forging heating number deformation amount are reasonably distributed, and the grain refining forging method of the large-scale forged parts is formed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

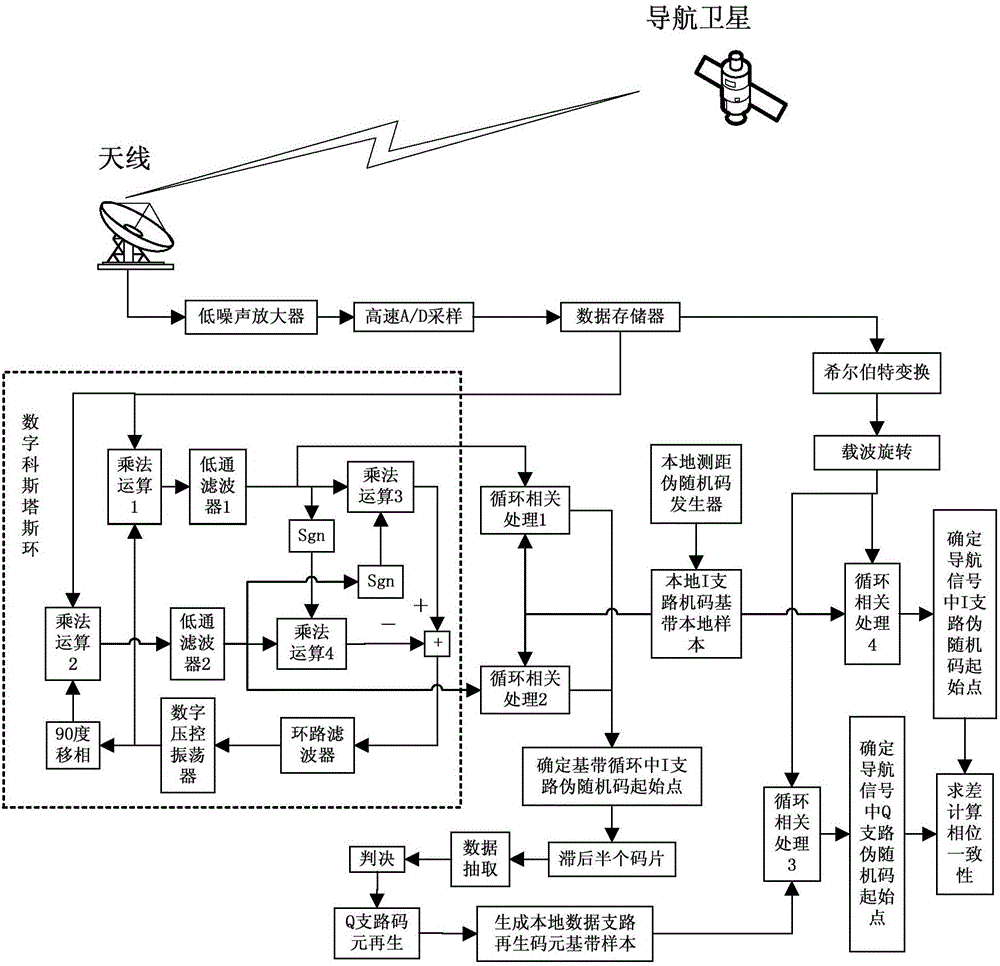

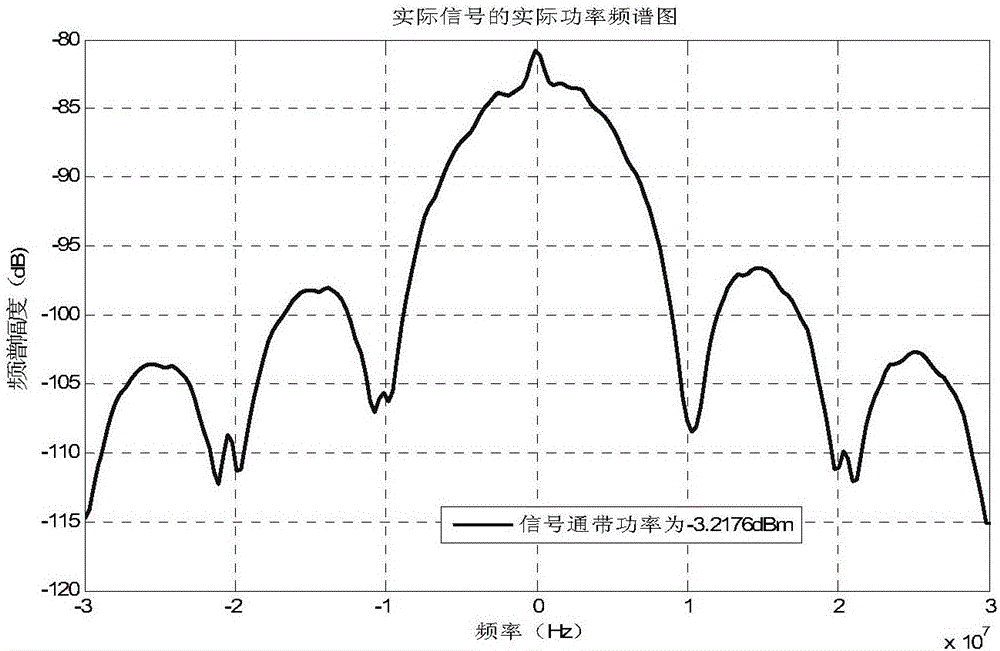

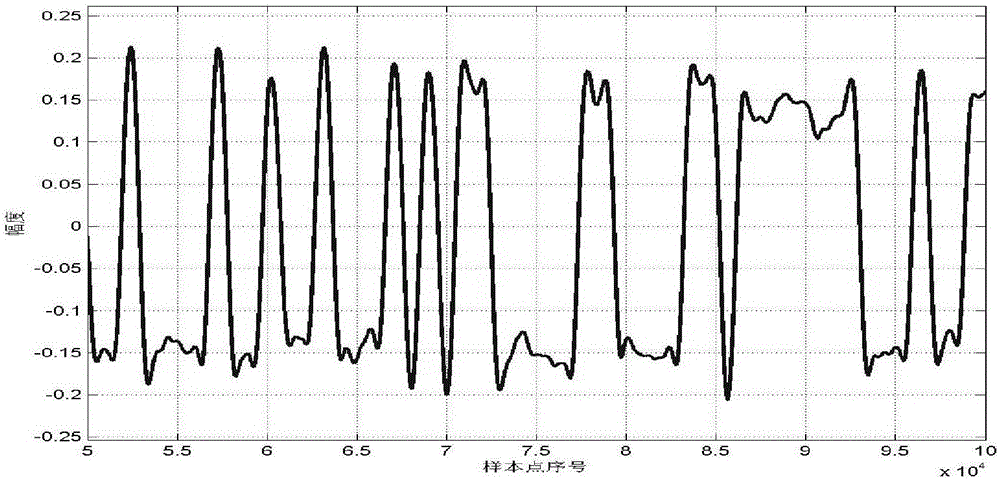

On-orbit navigation signal IQ phase consistency calibrating method

ActiveCN106226793AAvoid Calibration ErrorsPrecise determination of phase delay relationshipSatellite radio beaconingQuadrature demodulationCoded element

The invention discloses an on-orbit navigation signal IQ phase consistency calibrating method, and belongs to the field of satellite navigation. The method includes the steps of conducting high-speed sampling for navigation radiofrequency signals, conducting quadrature demodulation for the intercepted navigation signal sampling data to obtain two roadbed band data, determining the pseudo-random code start point of a navigation signal I branch through circular correlation processing, extracting the Q-path baseband signals according to the pseudo-random code sheet interval with the half code sheet delayed than the start point, regenerating code elements of the navigation signal Q branch, conducting circular correlation respectively for the navigation signal data by using the local I branch pseudo-random code and regenerated Q branch code elements, respectively determining the pseudo-random code start points of the I branch and the Q branch in the navigation signals, and calculating the phase consistency of a navigation signaling channel in combination with sampling rate. The method is applied in a digital domain, the calibrate errors caused by self zero value error of reception equipment in conventional test equipment can be avoided, and the calibrating precision is high.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

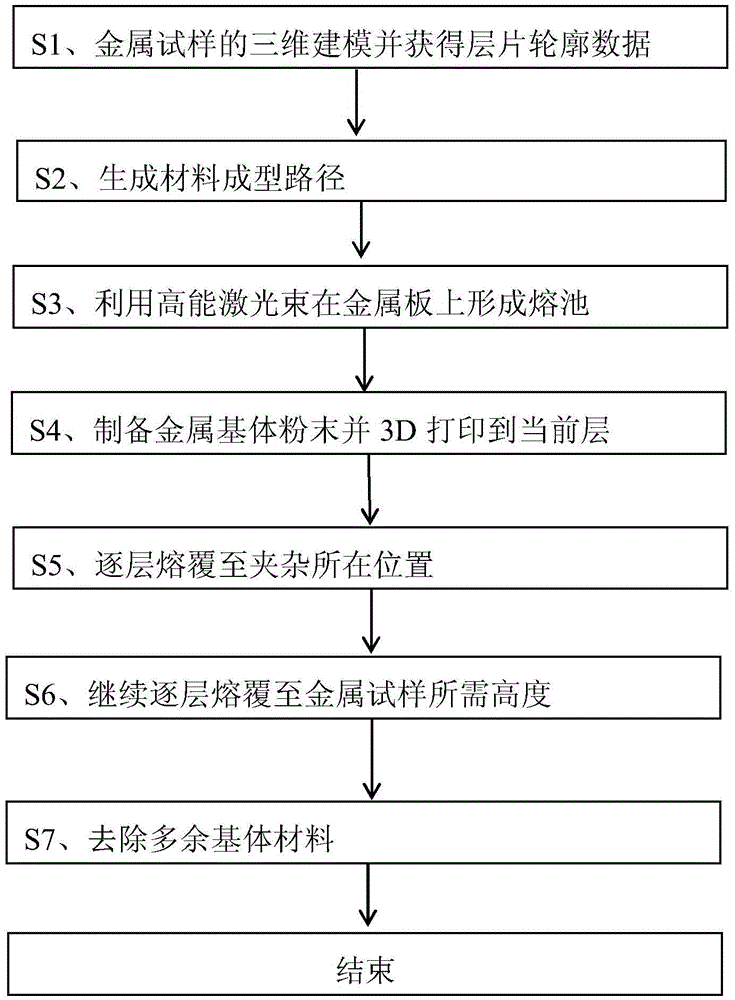

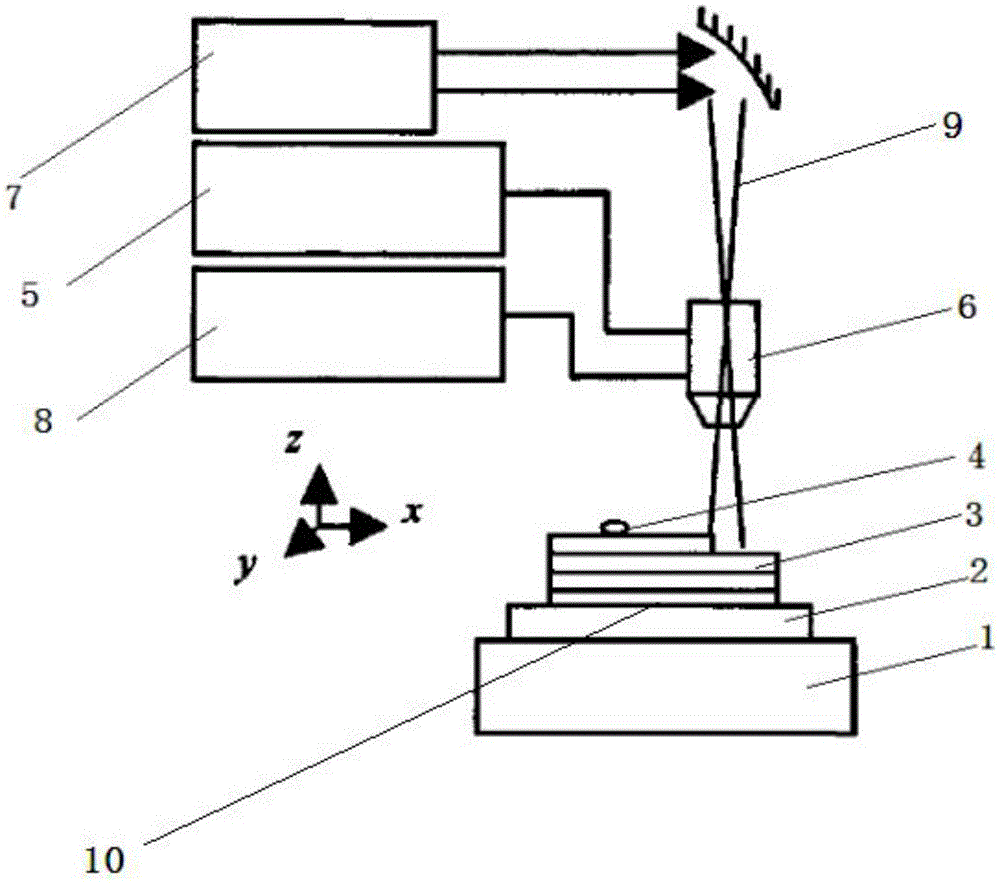

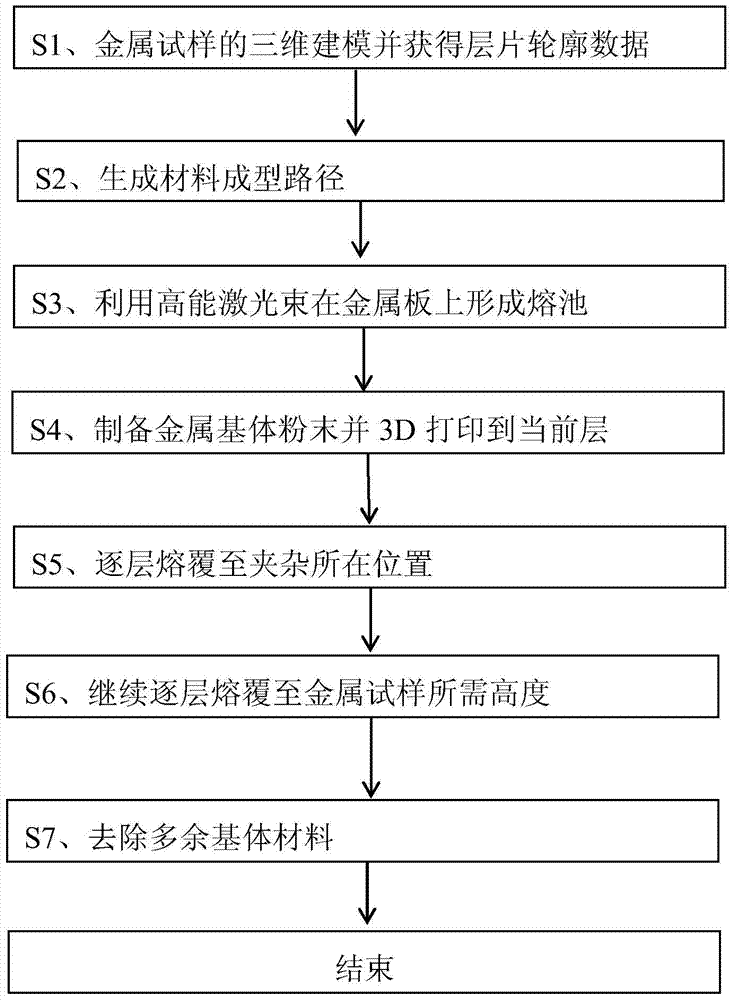

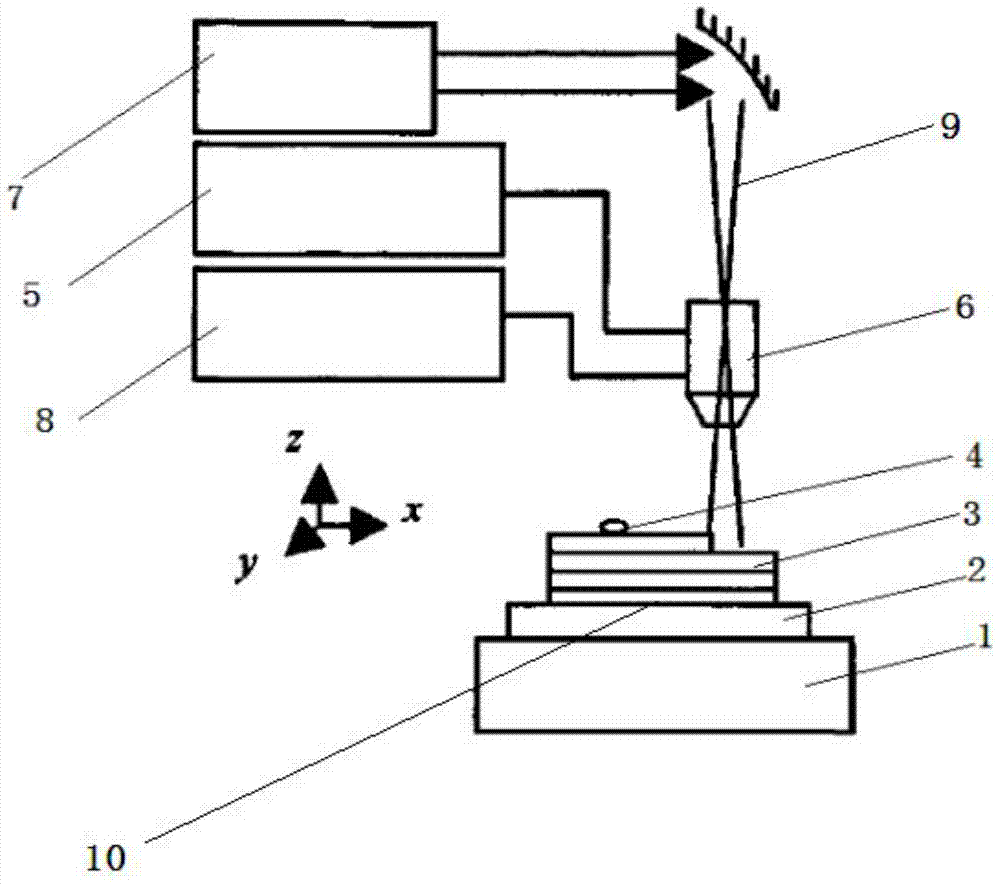

Three-dimensional printing method of metal sample containing built-in inclusion

ActiveCN105598449AAccurate locationAccurately determine the original shapeAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMolten bath

The invention discloses a three-dimensional printing method of a metal sample containing a built-in inclusion. The method comprises the following steps that a three-dimensional model of the metal sample is built, and layer contour data of the model is obtained; by means of a laser cladding forming method, a molten bath is formed on a metal plate through a high-energy laser beam; powder of the metal sample serves as a base material, the powder is conveyed into the molten bath to be molten through a powder feeding device and a powder nozzle, a current layer is printed, and cladding is conducted layer by layer to reach the specified location where the inclusion is located; the inclusion with known morphology and composition is fixed at the specified location, and layer-by-layer cladding forming is conducted continuously till the metal sample reaches the required height. According to the three-dimensional printing method of the metal sample containing the built-in inclusion, the laser cladding forming technology is adopted, and the inclusion with the known morphology and composition is put into a metal substrate during cladding; on one hand, metal samples with various complex shapes can be prepared; on the other hand, it is guaranteed that on the premise that the continuity of the metal substrate is not destroyed, the specific location and original morphology of the inclusion are positioned accurately, and the precision and accuracy of research on the inclusions in metal are improved.

Owner:YANSHAN UNIV

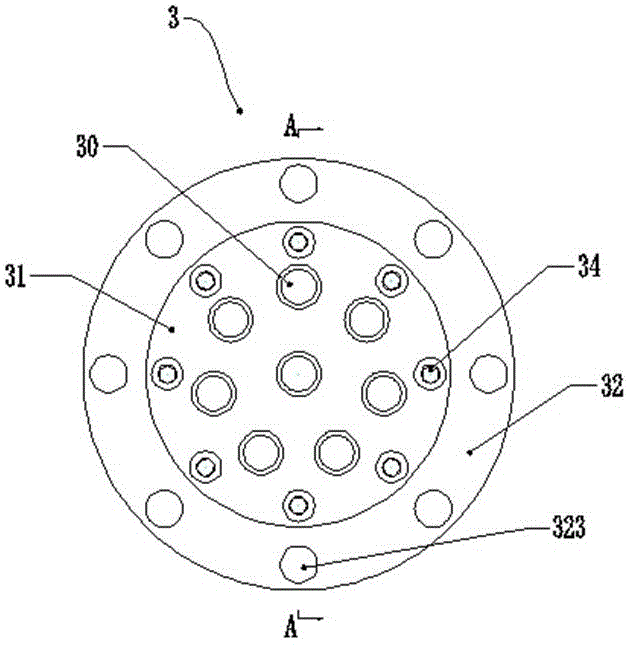

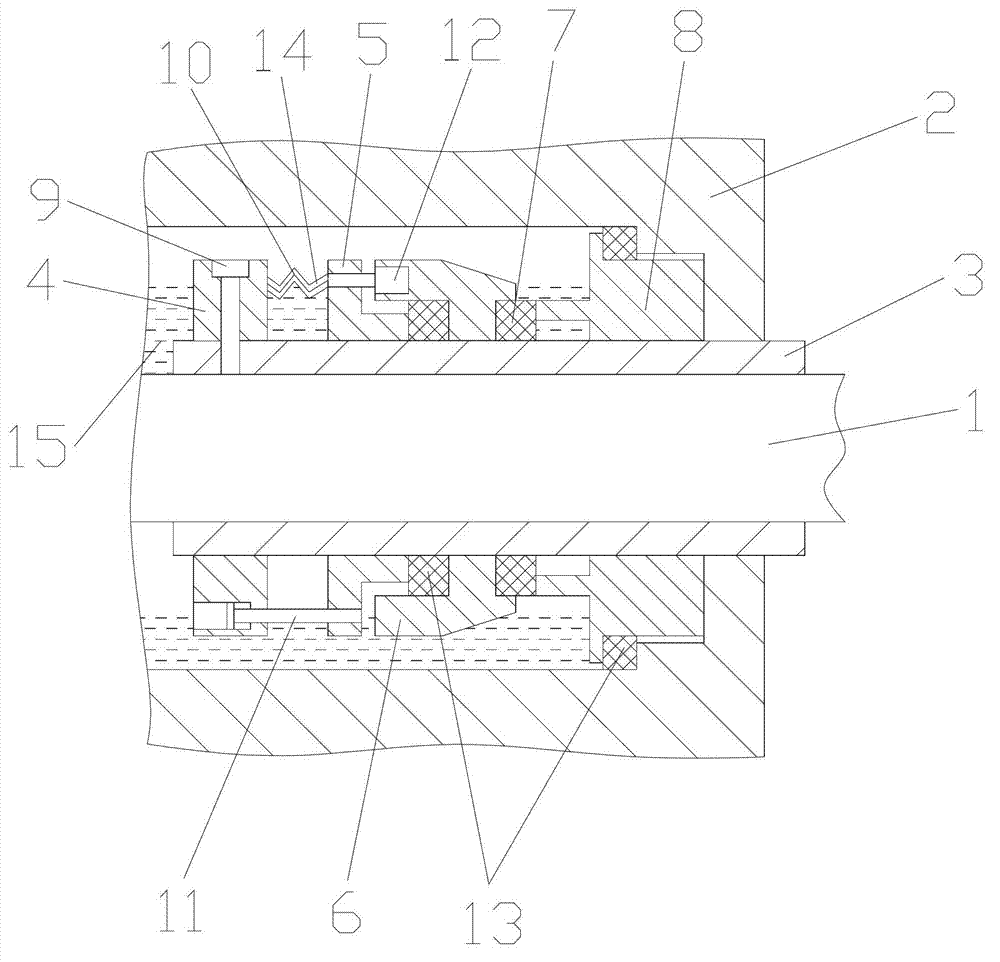

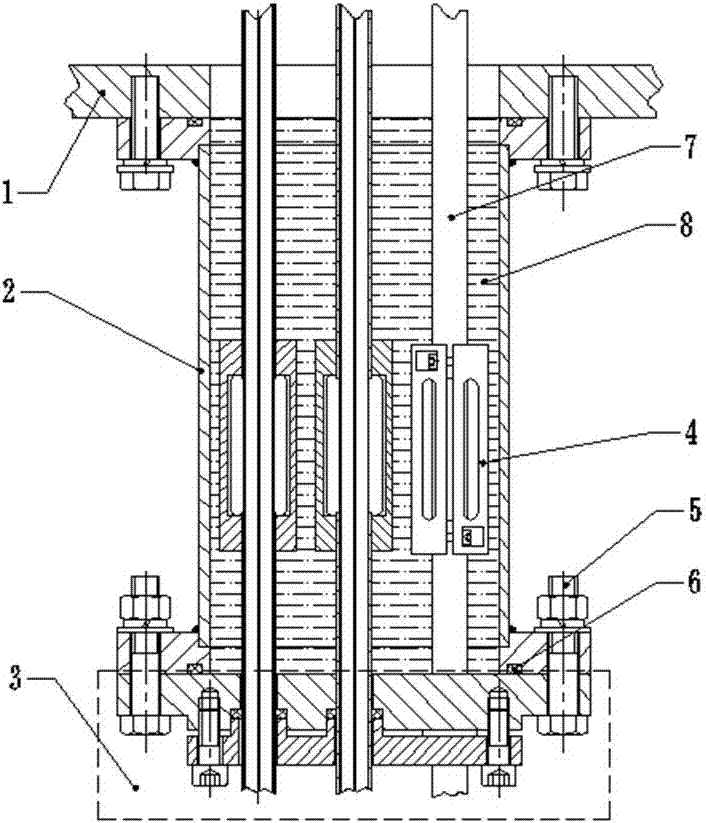

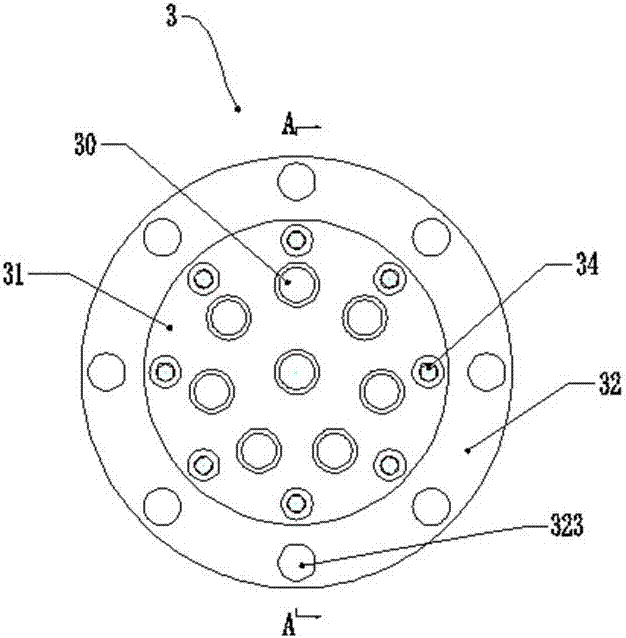

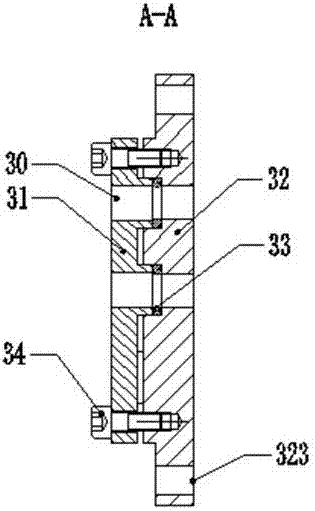

Coaxial radio frequency cable run-through sealing part

InactiveCN105633701ATo achieve the two requirements of sealingGuaranteed signal transmission performanceCouplings bases/casesCable junctionsUltrasound attenuationElectrical conductor

The invention provides a coaxial radio frequency cable run-through sealing part. The sealing part comprises a circular adhesive pouring cylinder, a cable fixing board, an isolation assembly and cables, wherein more than two cable fixing holes for fixing and sealing cables are formed in the cable fixing board; the cable runs through the cable fixing holes and the adhesive pouring cylinder to enter a sealed container; the outer sheath on one section, in the middle of the adhesive pouring cylinder, of the corresponding cable is peeled off to form an adhesive permeating section; the exterior of the adhesive permeating section is surrounded by the isolation assembly; an adhesive inlet hole is formed in the isolation assembly; one end of the adhesive pouring cylinder is connected with the cable fixing board through a second flange; and the adhesive pouring cylinder is full of liquid sealant for sealing and blocking slot leakage among cables and the internal slot leakage of cable external conductors. According to the coaxial radio frequency cable run-through sealing part, the problem existing in sealing multiple cables led out of the sealed container is solved; meanwhile, the cable inner sealing and cable outer sealing are realized; and therefore, the coaxial radio frequency cable run-through sealing part has the advantages of no extra attenuation in signal transmission, simple structure, and reliable sealing performance.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

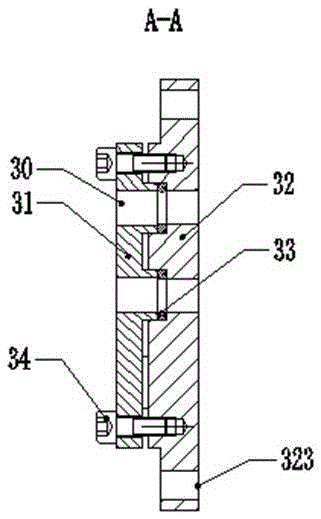

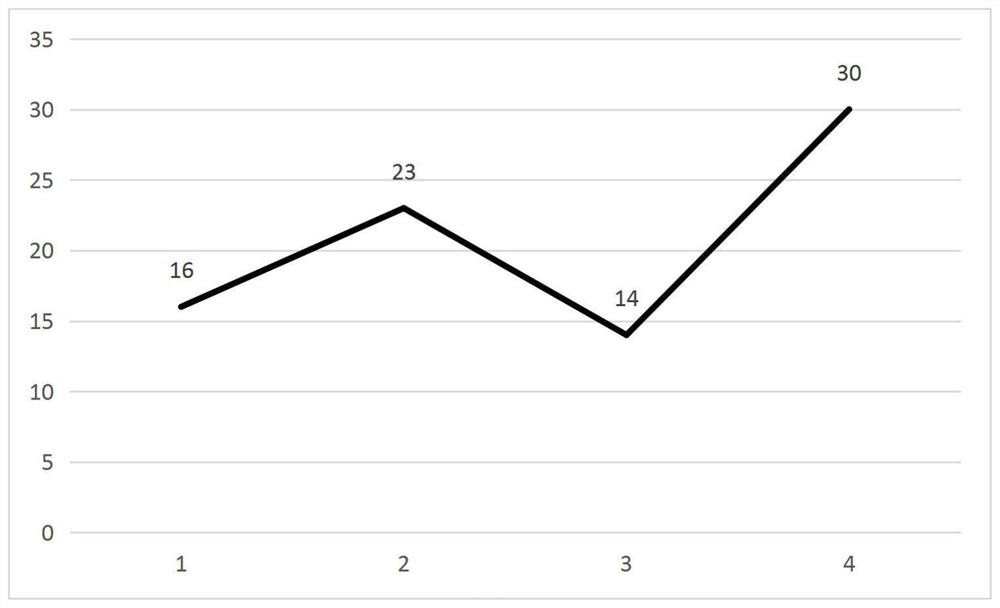

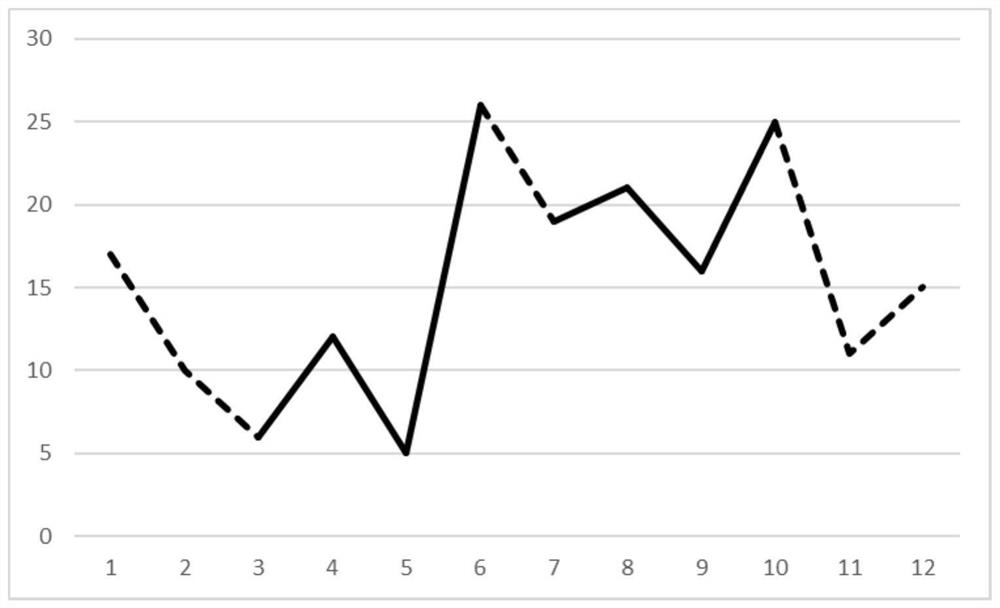

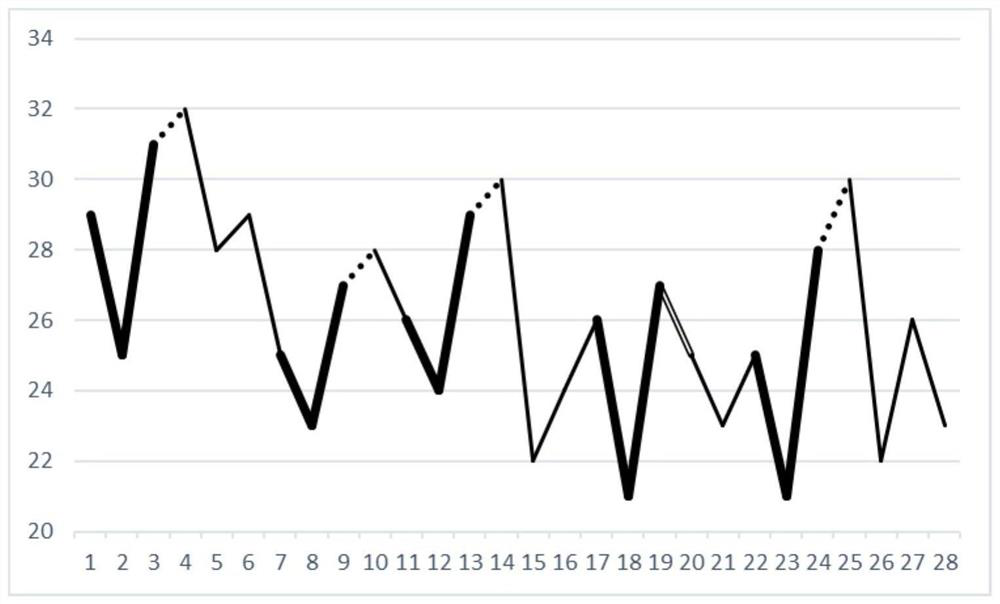

Order-preserving sequence pattern mining method

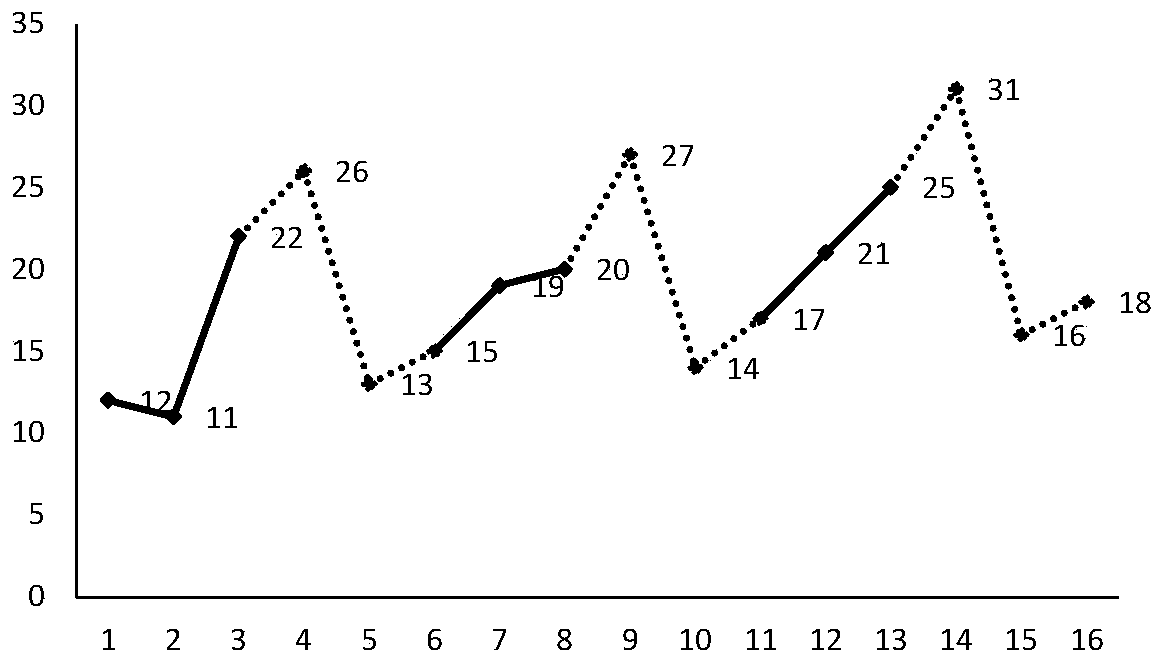

InactiveCN111581262AIntegrity guaranteedSignificant progressData miningKnowledge representationDigital dataEngineering

The invention discloses an order-preserving sequence pattern mining method and relates to the technical field of electric digital data processing. According to the method, a candidate mode is generated by using a mode fusion method; the number of candidate modes is reduced, and the mode support degree of the candidate modes is calculated through a series of conversion and verification steps. The defects that in the prior art, for mining frequent patterns from a time sequence, solving accuracy, generality and completeness are difficult to consider at the same time, it is difficult to ensure that important information is not lost when the time sequence is processed, and it is difficult to analyze key trends by mining the frequent patterns are overcome.

Owner:HEBEI UNIV OF TECH

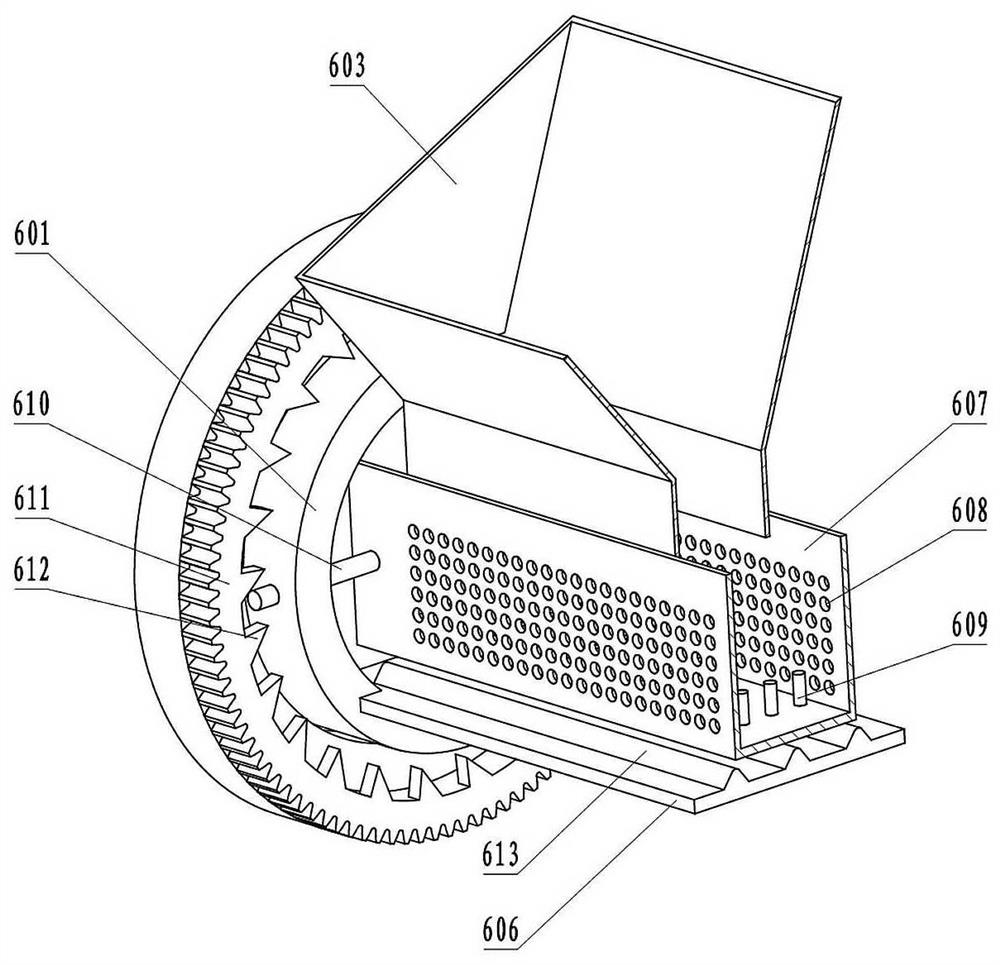

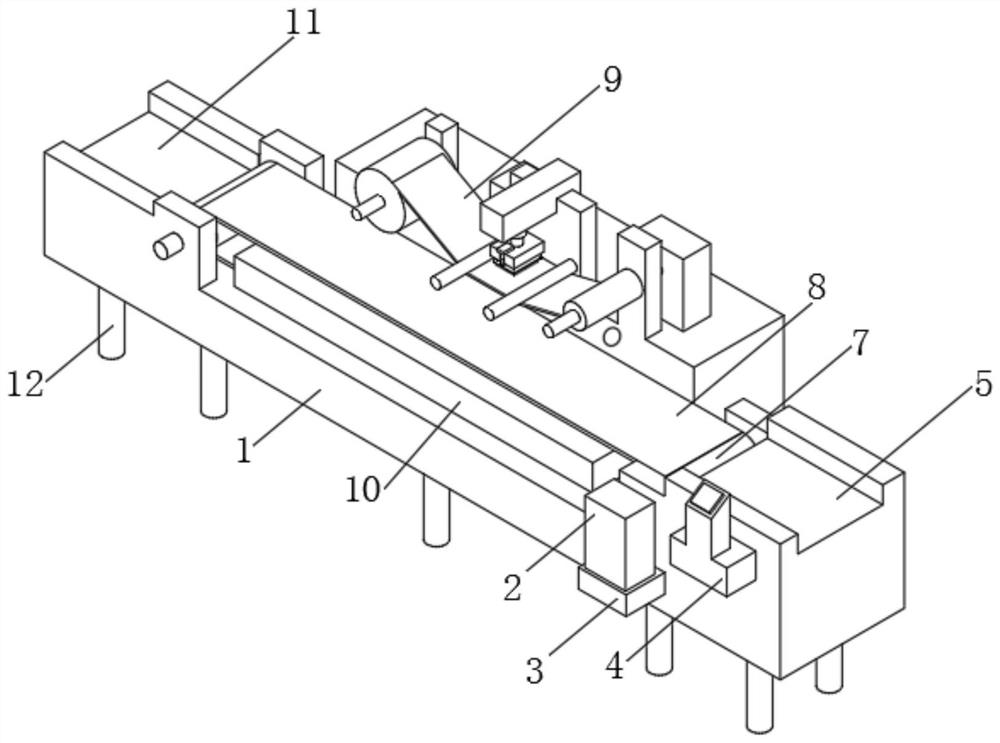

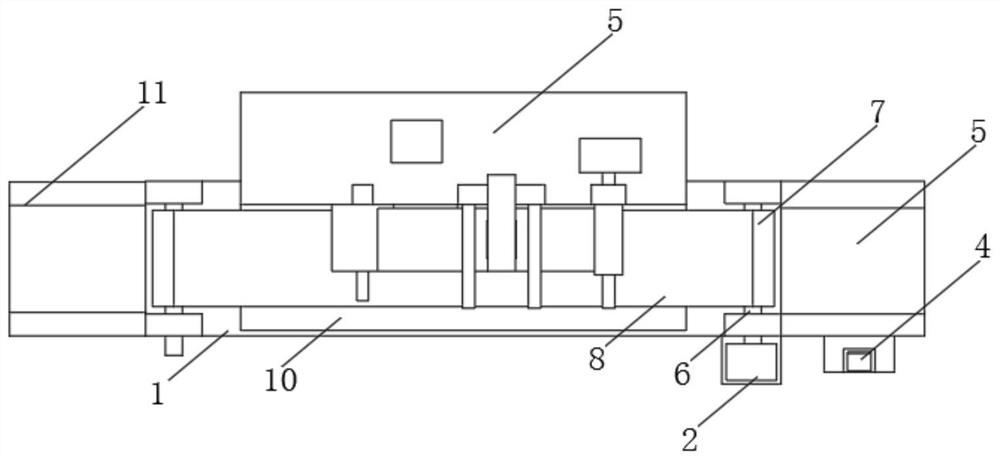

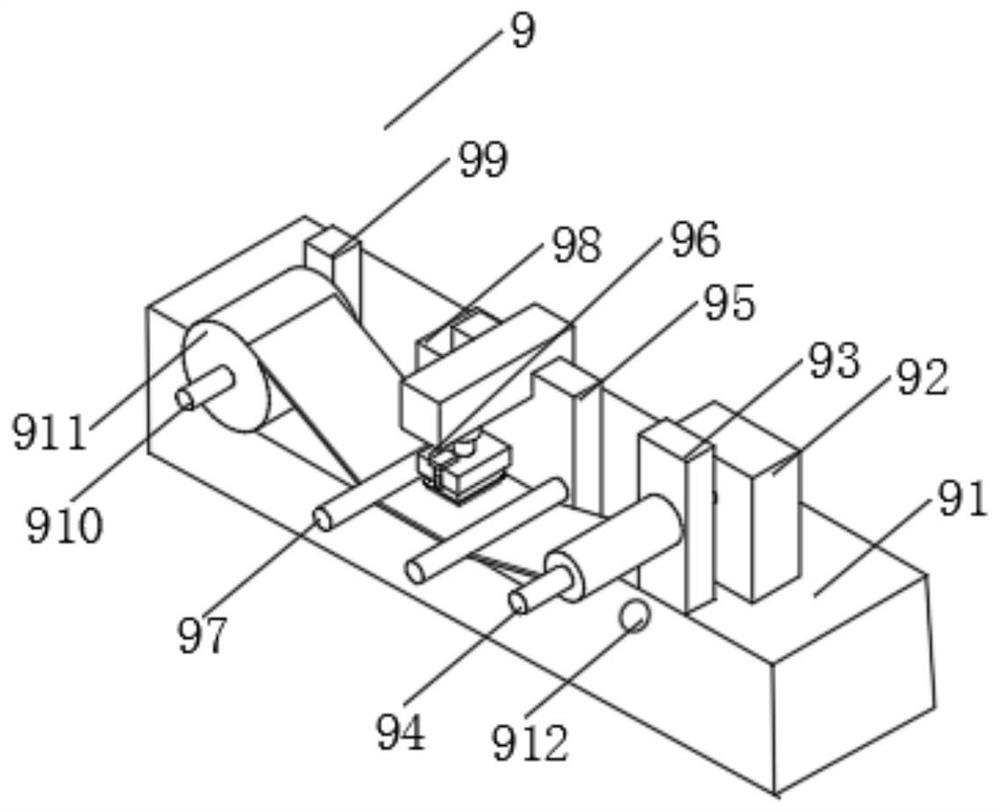

Open-loop reciprocating type diamond wire cutting machine

InactiveCN106181728ASolve the problem of machining inner holeDoes not break continuityRevolution surface grinding machinesReciprocating motionWire cutting

The invention discloses an open-loop reciprocating type diamond wire cutting machine. The open-loop reciprocating type diamond wire cutting machine comprises a diamond wire in the X-axis direction or the Z-axis direction, and a workbench arranged below or beside the diamond wire, wherein the diamond wire is installed on a reciprocating motion device in the X-axis direction or the Z-axis direction, the reciprocating motion device comprises a linear guide rail in the X-axis direction or the Z-axis direction, a horizontal or vertical bow-shaped frame and a crank-link mechanism driven by a motor, the bow-shaped frame is installed on the linear guide rail in a sliding manner through sliding blocks, the crank-link mechanism comprises a crank and a connecting rod which are hinged to each other, the crank is installed on the output shaft of the motor, the connecting rod is hinged to the bow-shaped frame, the two ends of the diamond wire are connected with the two ends of the bow-shaped frame detachably in structure, and the workbench is arranged on an X-axis, Y-axis and Z-axis linkage device. According to the open-loop reciprocating type diamond wire cutting machine, a new technology for machining inner holes in hard brittle materials is provided, the blank of traditional technologies for machining inner holes is filled up, and the use ratio of materials is increased.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

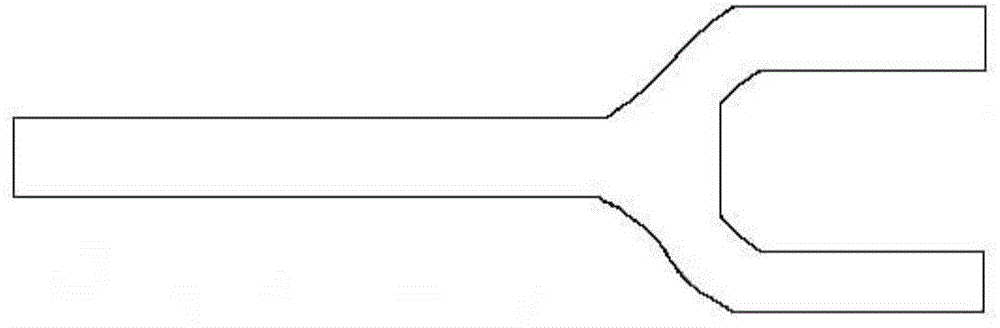

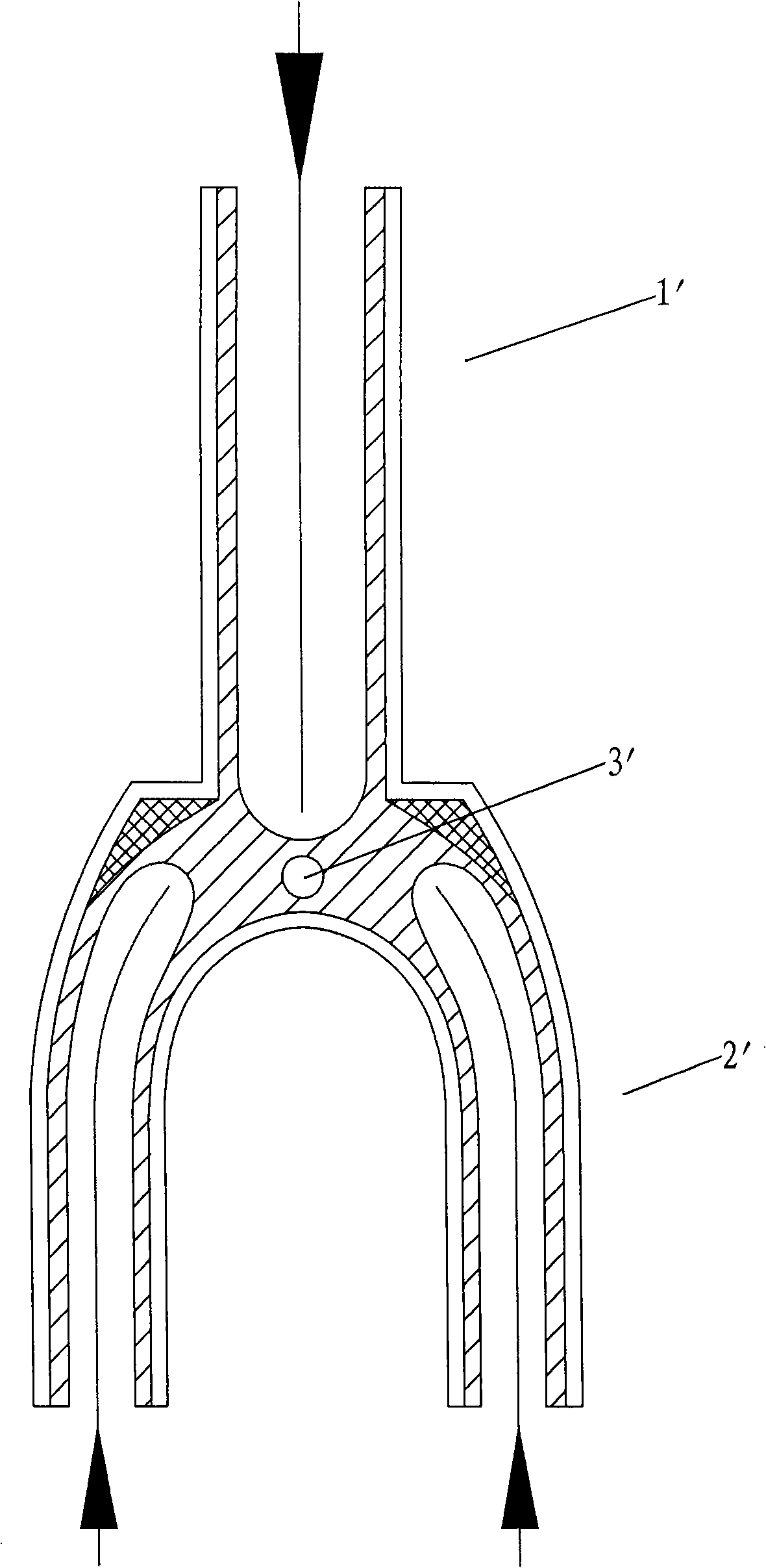

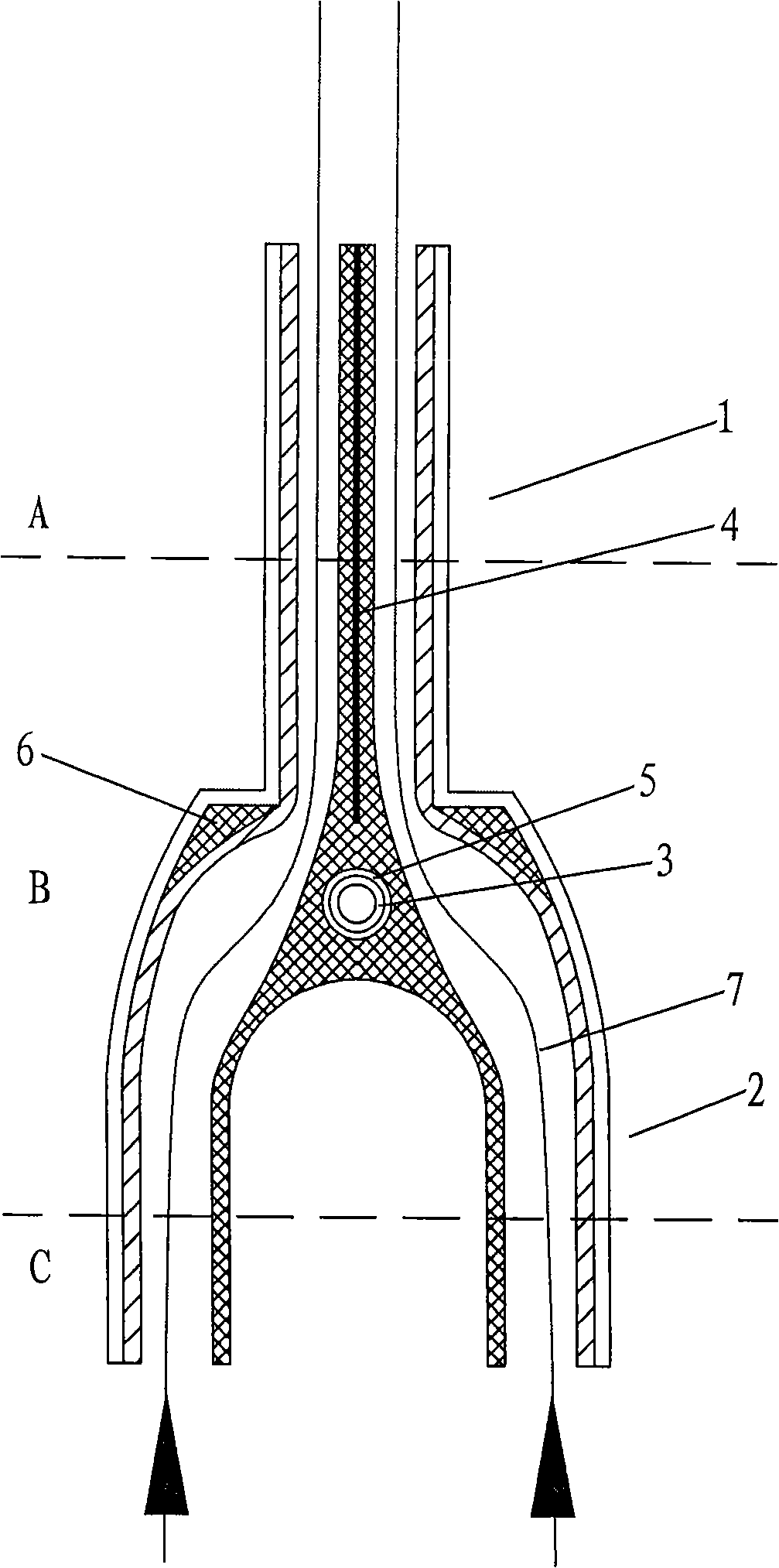

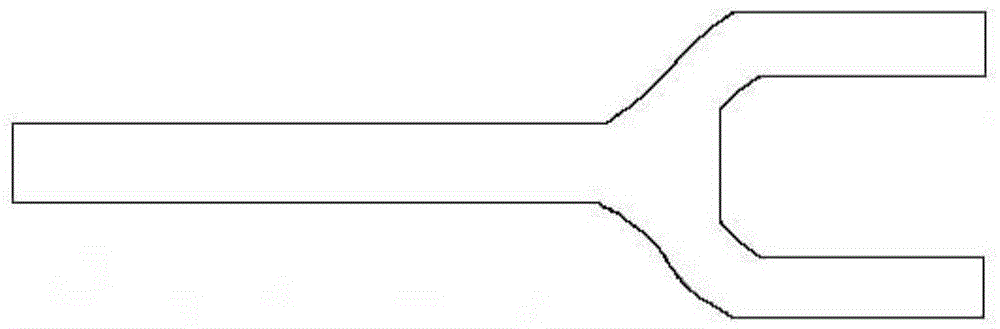

Method for manufacturing front fork of compound material

ActiveCN101318533AGuaranteed support strengthImprove support strengthSteering deviceCycle framesFiberYarn

A manufacturing method for a front fork of a composite bicycle is characterized in that a vertical pipe and two breeches pipes are pre-shaped by two wind pipes; the steps include: two bobbins are respectively rolled by composite materials; the wind pipes are arranged in the two bobbins; the lower parts of the two bobbins are separated to form two breeches pipes; while the upper parts of the two bobbins are combined together to form the vertical pipe; then the inner core of a brake hole provided with a through hole is arranged in the position of a brake between the two bobbins; then yarn complementing is carried out at the connecting location of the two bobbins according to the shape of the front fork; finally the bobbins are arranged in a die for being heated, solidified and shaped. The wind pipes are directly communicated with the vertical pipe by the breeches pipes; the wind pipes can correct the consequent property of the fiber of the composite yarn and can ensure the supporting intensity of the front breeches pipe; the vertical pipe of the front breeches pipe is combined together and shaped by two bobbins; the combining location of the two bobbins naturally forms one reinforcing rib in the vertical pipe; the arrangement of the inner core of the brake hole is to integrally shape the penetrating hole of the brake on the front breeches pipe when the front breeches pipe is shaped without the working procedure of secondary drilling, thus the intensity of the front breeches pipe is not affected under the premise of ensuring the coax of the penetrating hole.

Owner:XIAMEN KEENTECH COMPOSITE TECH CO LTD

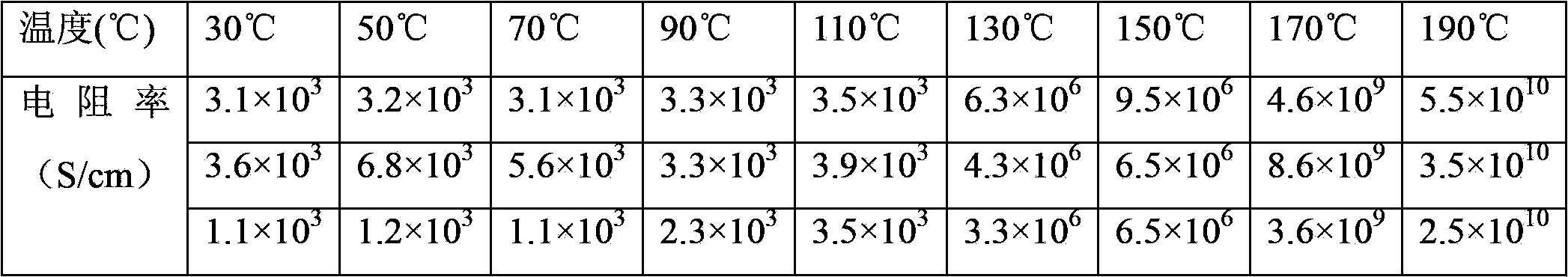

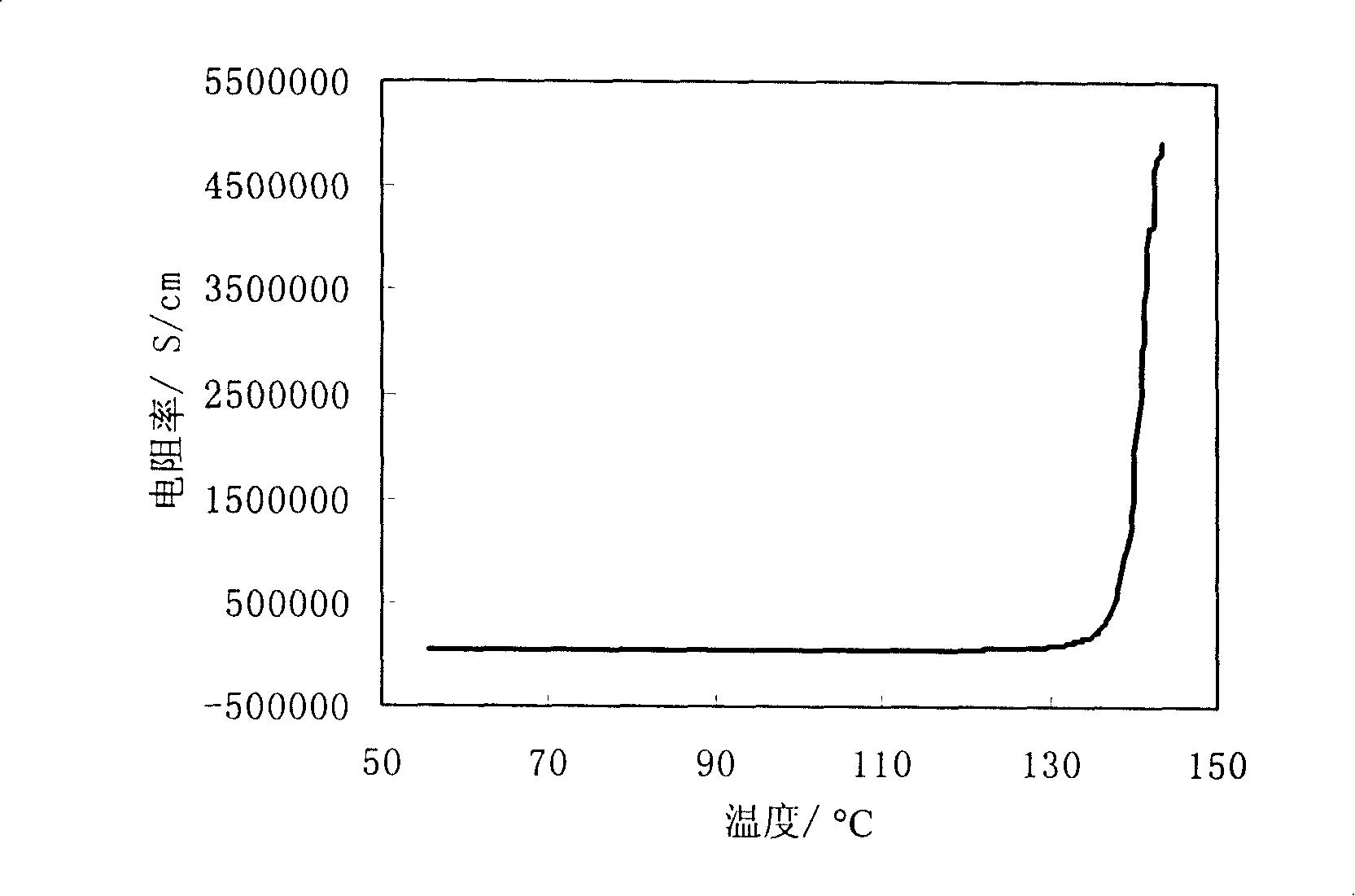

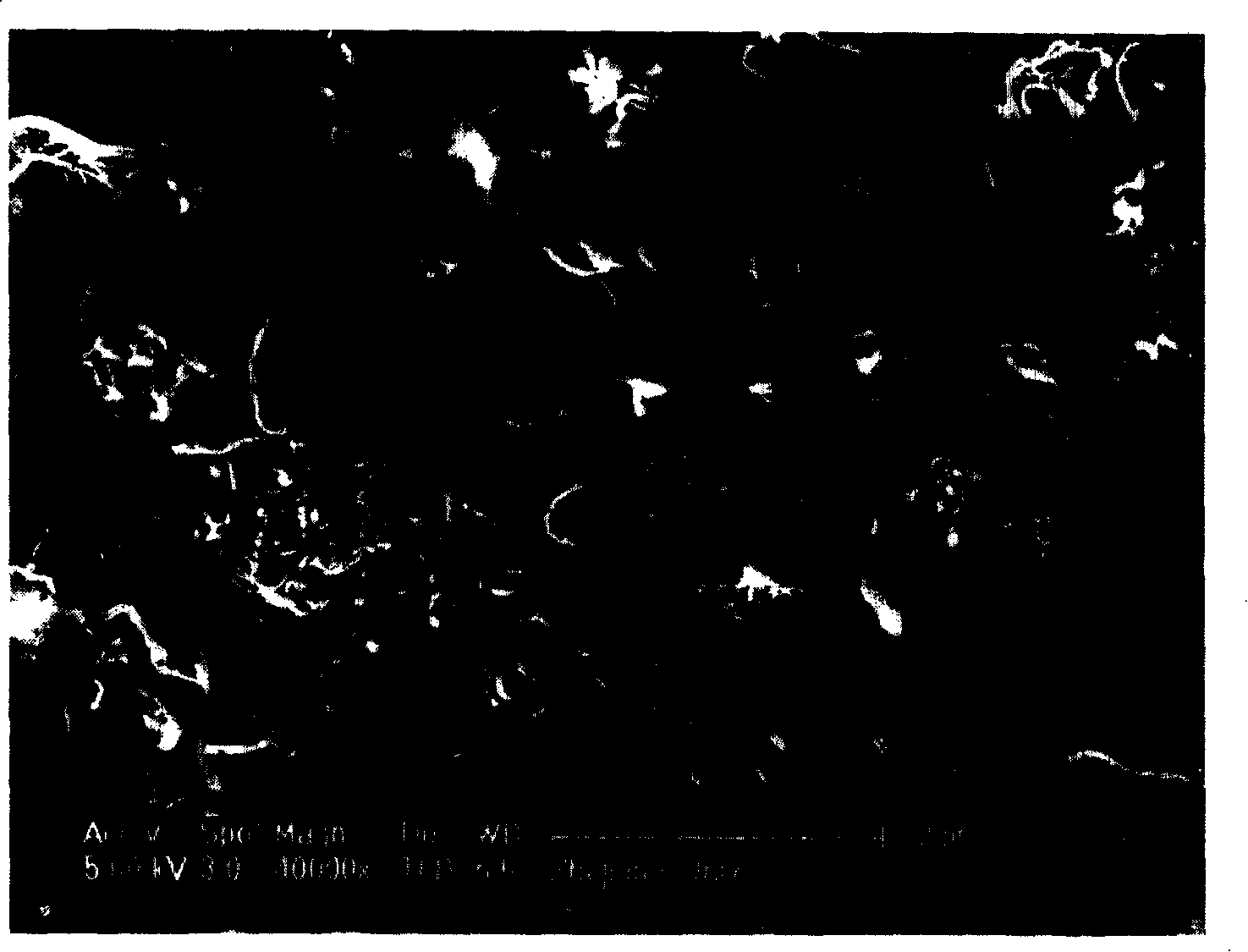

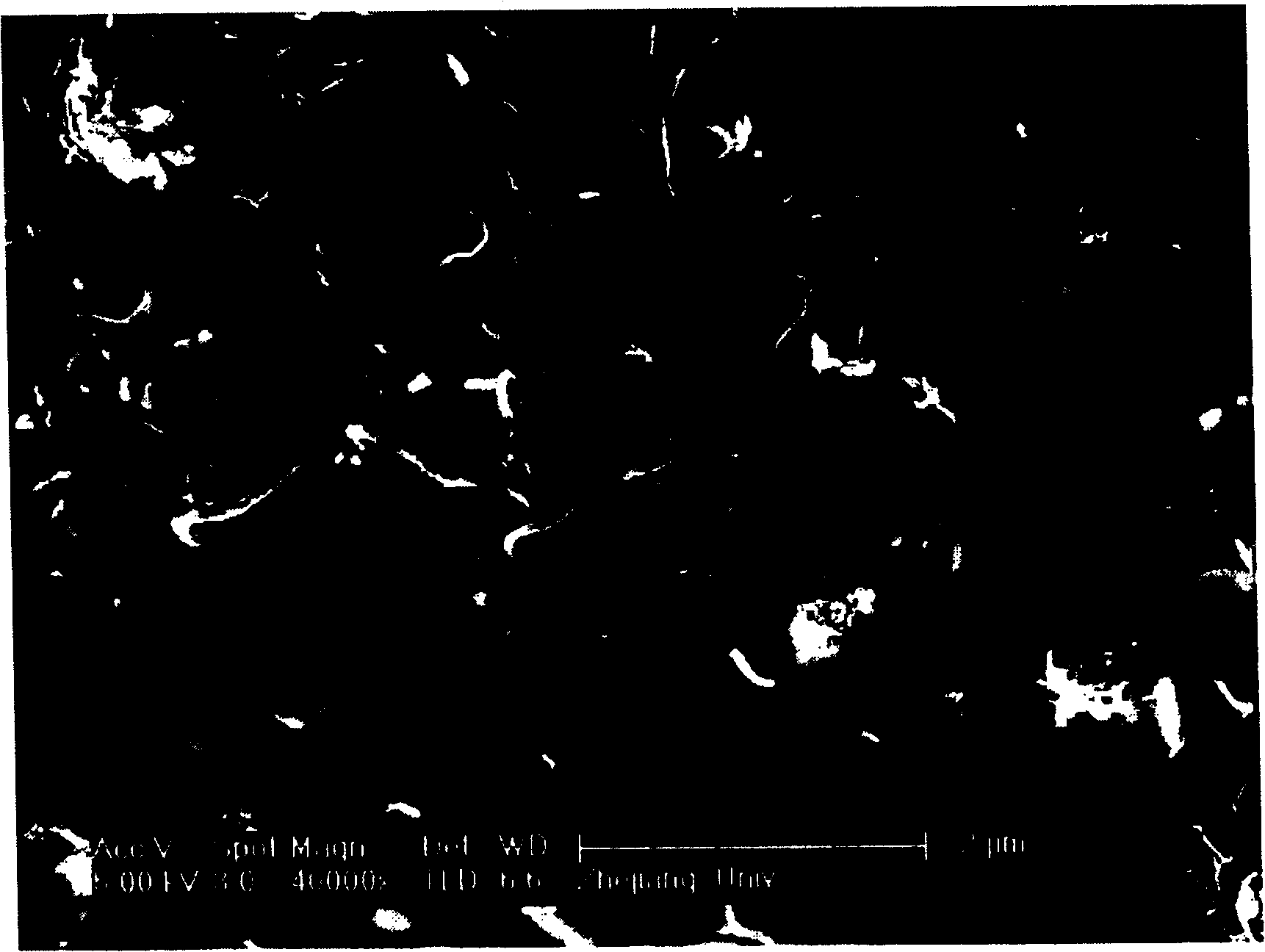

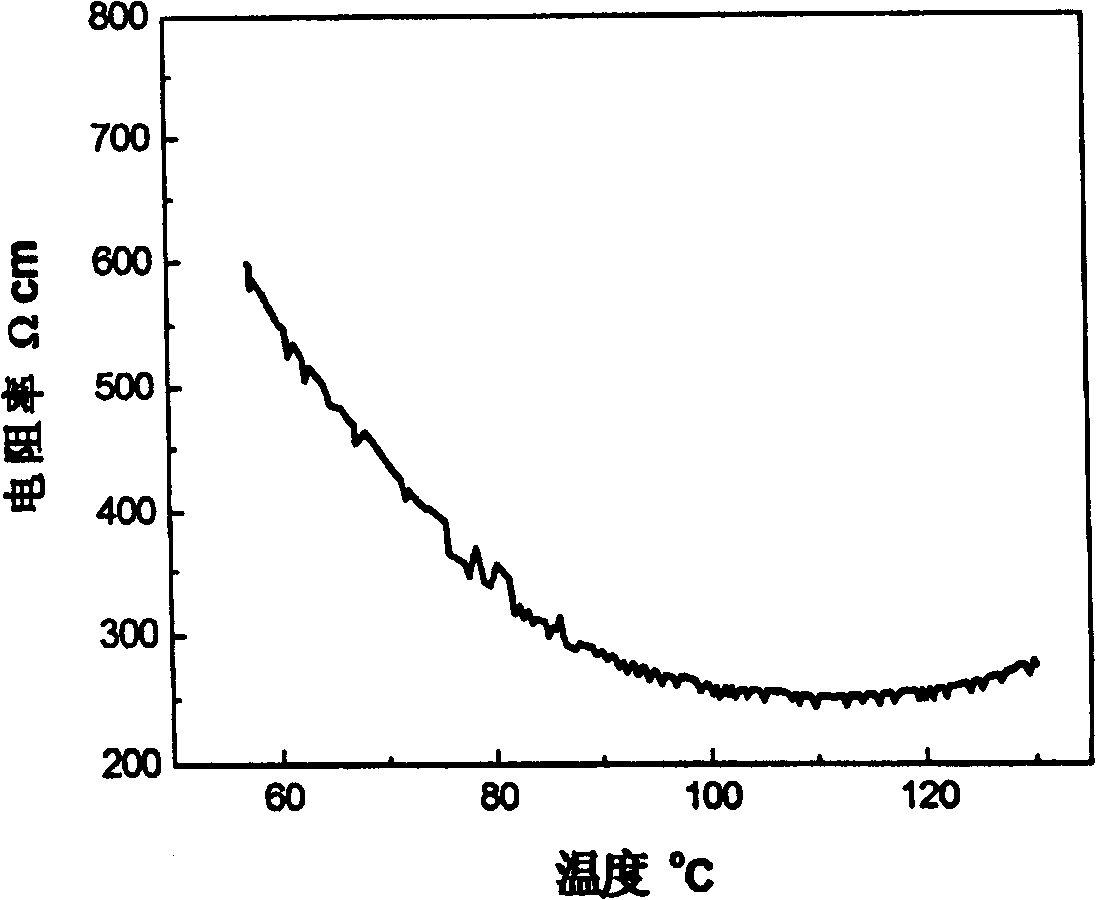

Composite material for electric heating and overheat protection and prepn. thereof

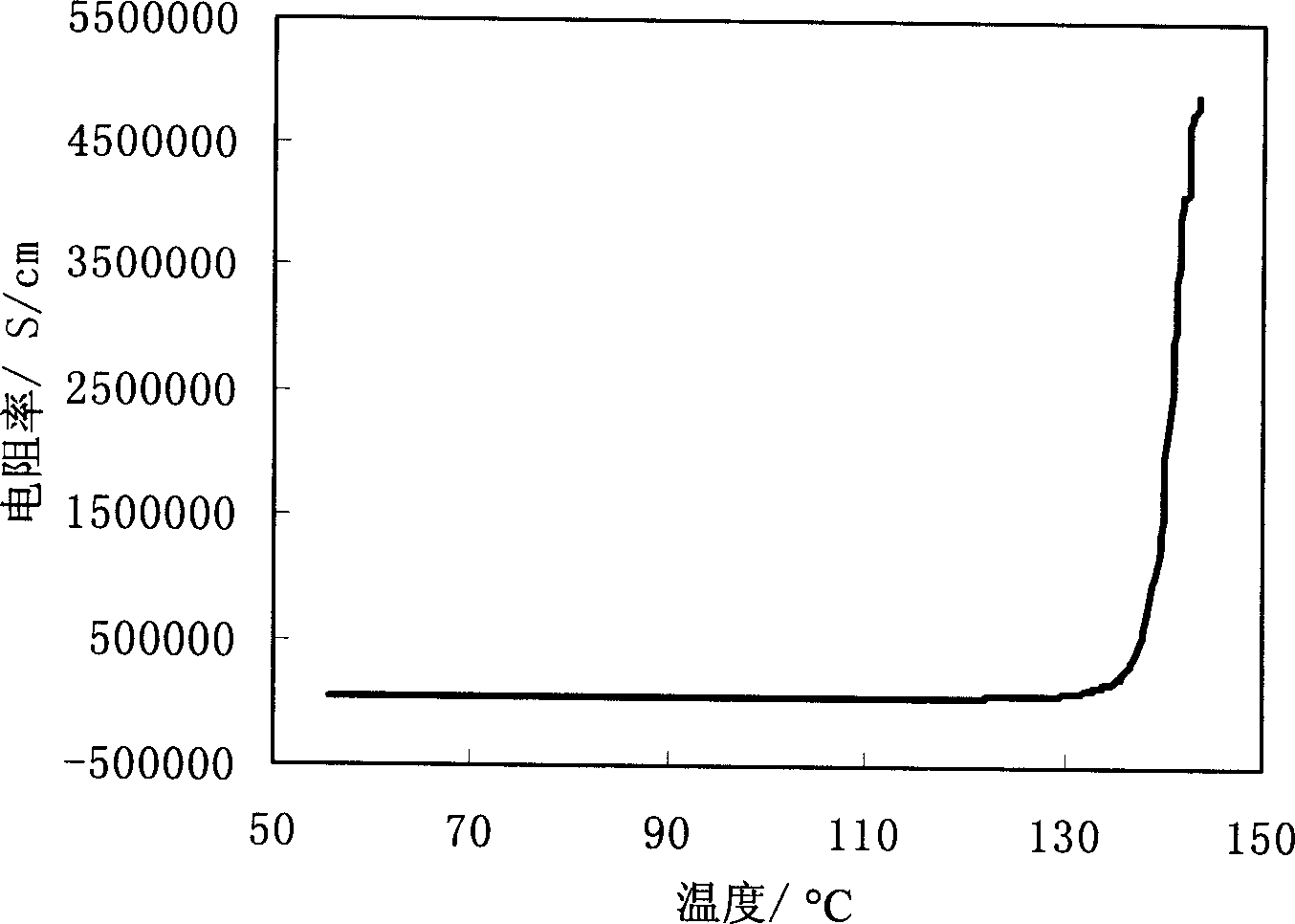

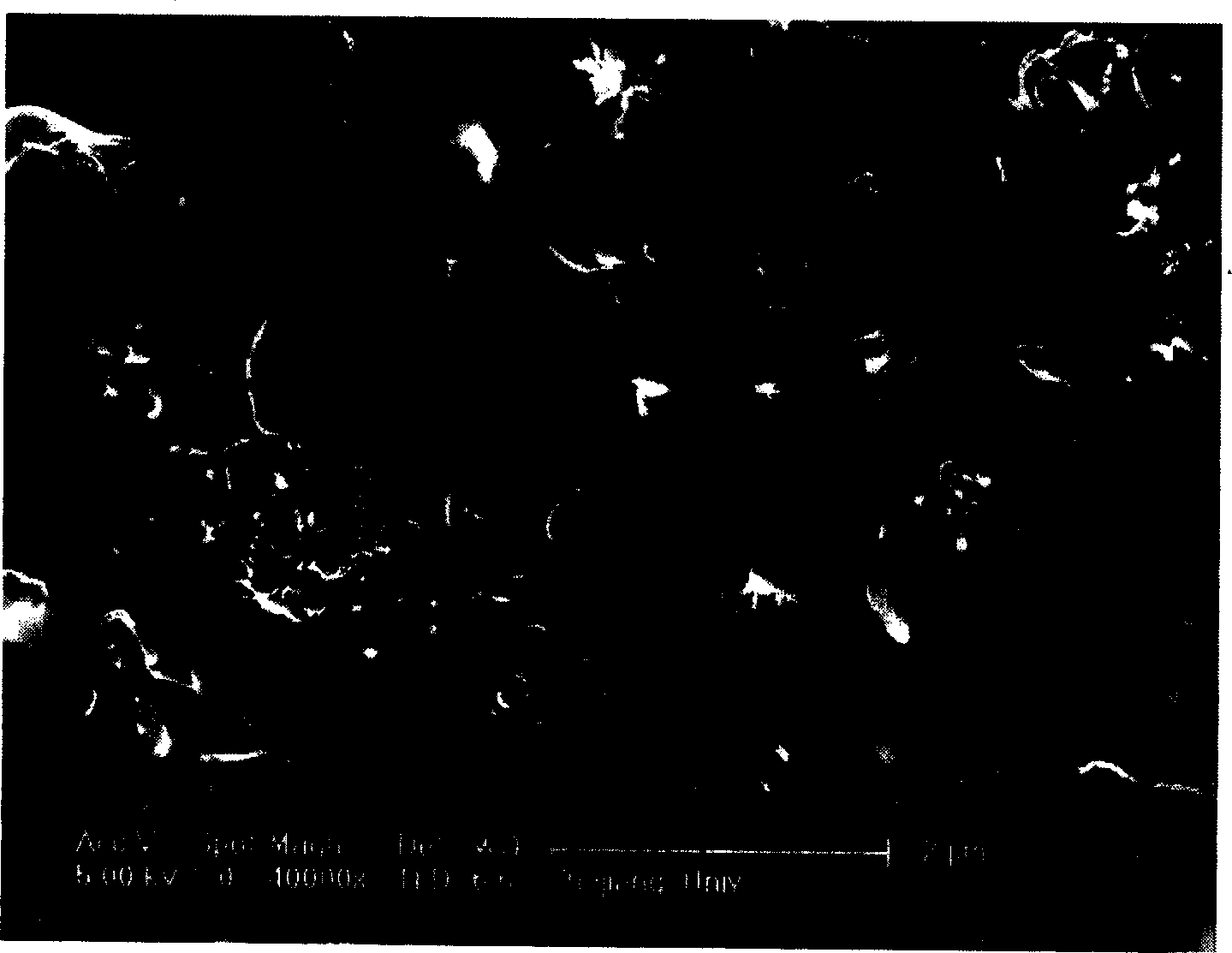

InactiveCN1834143AGood PTC performanceDoes not break continuityNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsRoom temperatureCarbon nanotube

This invention discloses a kind of composite materials for electroheating and thermal-overload protection, which comprises 4~7wt% carbon nanotubes and 96~93wt% high-density polyethylene. In this invention, melting blending is adopted and the steps are as follows: carbon nanotube powders and high-density polyethylene particles are weighed according to the ratio above and put into a mould after mixing to homogeneity at a temperature of 140~170 deg. C. The mixture is first preheated at a temperature of 165~180 deg. C for 5~20 minutes and compressed under a pressure of 5~20MPa and 10~30MPa for 5~20 minutes, respectively. It is then demoulded and cooled to room temperature. The composite materials in this invention adopt high-density polyethylene as matrix and carbon nanotubes as additives and have the advantages of lower additive amount compared to carbon black and no damnification to matrix continuity. This kind of materials has good PTC properties which promise both electroheating and thermal-overload protection functions and self-limited temperatures. Besides, this invention also has the advantages of simple technique, easy operation and considerable repeatability and is thus suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

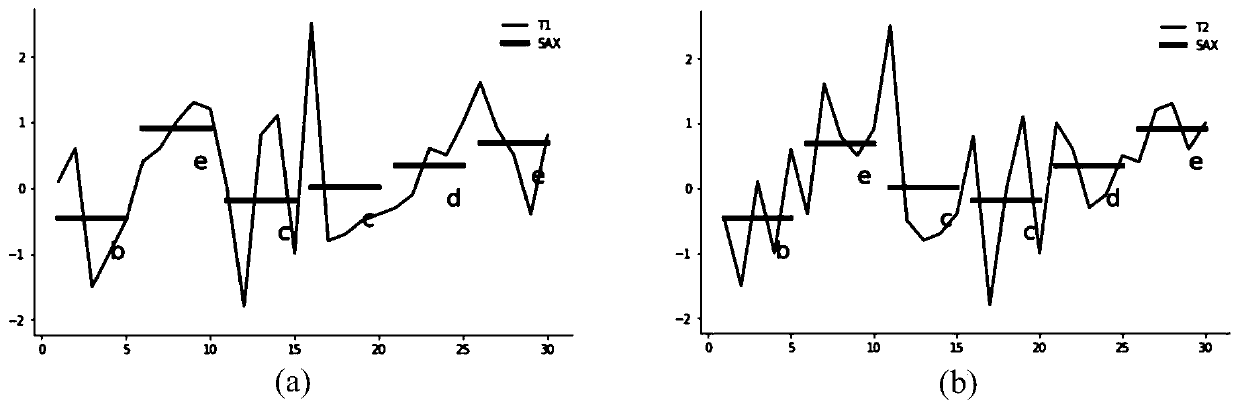

Order-preserving sequence rule mining method

InactiveCN112905689AStrong display meaningReduce the number of timesVisual data miningStructured data browsingPhysicsConfidence threshold

The invention relates to an order-preserving sequence rule mining method, which comprises the following steps of: obtaining all frequent order-preserving sequence modes corresponding to a time sequence, forming a frequent order-preserving sequence mode set, setting a minimum confidence coefficient threshold value minconf, and calculating a prefix sub-mode x of a frequent order-preserving sequence mode y, if the relative sequence of the prefix sub-modes is a frequent order-preserving sequence mode, obtaining an order-preserving sequence rule x = gt; y, iterating the process to obtain all order-preserving sequence rules; according to conf (x = gt; y) = sup (y) / sup (x), and x = gt is calculated; and finally, adding the order-preserving sequence rules of which the confidence is greater than or equal to a set minimum confidence threshold value minconf into the rule set R, calling the order-preserving sequence rules of which the confidence is less than minconf as strong order-preserving sequence rules, and calling the excavation of all the strong order-preserving sequence rules as order-preserving sequence rule excavation. According to the method, efficient frequent order-preserving sequence pattern mining is realized, then order-preserving sequence rule mining is performed on the frequent order-preserving sequence pattern, and an implicit relationship between the patterns is searched.

Owner:HEBEI UNIV OF TECH

Graphene-filled polypropylene composite material, and preparation method thereof

The invention belongs to the technical field of composite material, and relates to a graphene-filled polypropylene composite material, and a preparation method thereof. The graphene-filled polypropylene composite material comprises, by weight, 0.5 to 2 parts of grapheme and 98 to 99.5 parts of polypropylene. According to the graphene-filled polypropylene composite material, polypropylene is taken as the substrate, and graphene is taken as the filling material; grapheme possesses a two-dimensional periodic honeycomb lattice structure composed of carbon six-member rings, and electron moving speed in grapheme reaches 1 / 300 of light speed, and far exceeds moving speed of electron is common conductors, so that conductive demands can be satisfied by adding a small amount of grapheme, continuity of the substrate material is not influenced, easy processing advantage of high-molecular materials is maintained, the graphene-filled polypropylene composite material possesses excellent PTC performance, electrical heating and overheating protection performance, and temperature limiting effects. In addition, the graphene-filled polypropylene composite material is prepared via melt blending; technology processes are simple; operation is convenient; repeatability is excellent; and the graphene-filled polypropylene composite material is suitable for large-scale industrialized production.

Owner:HEFEI GENIUS NEW MATERIALS

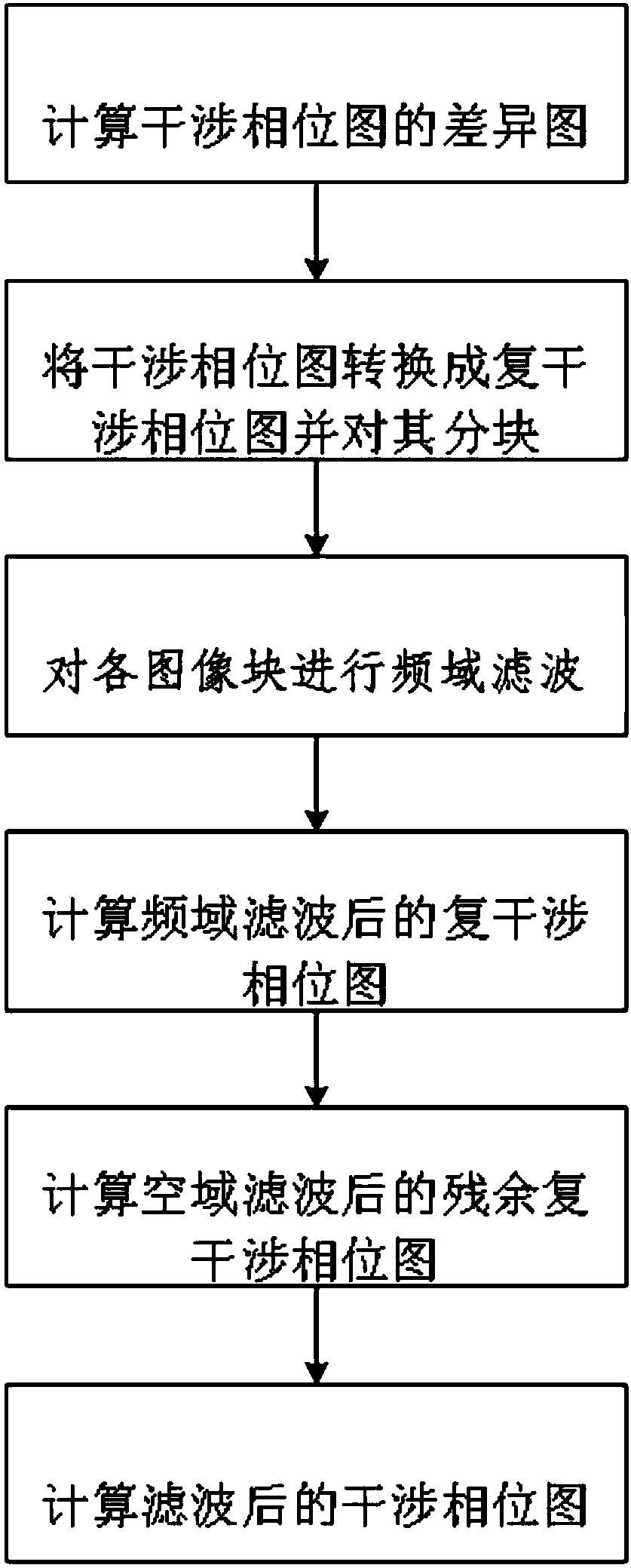

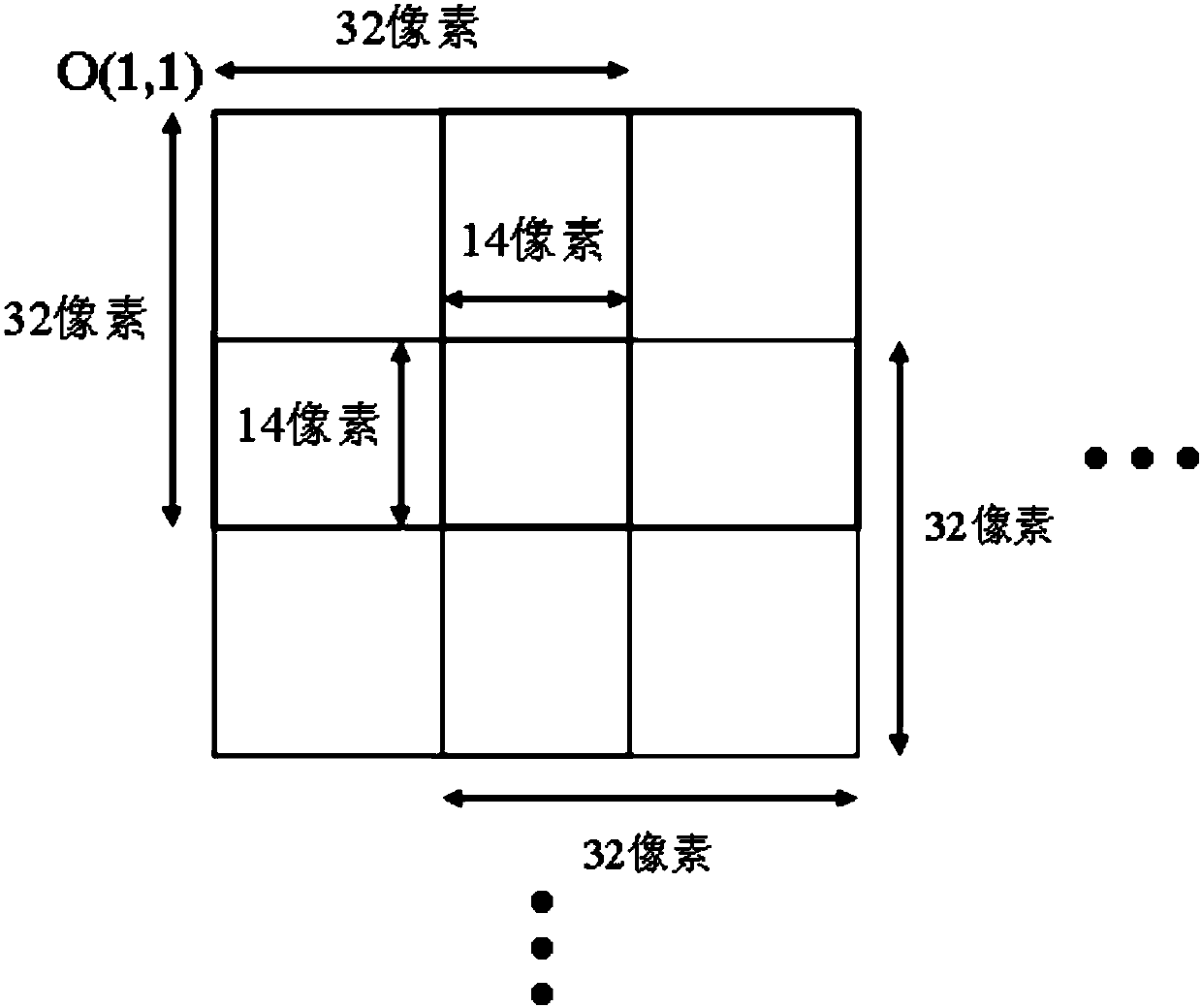

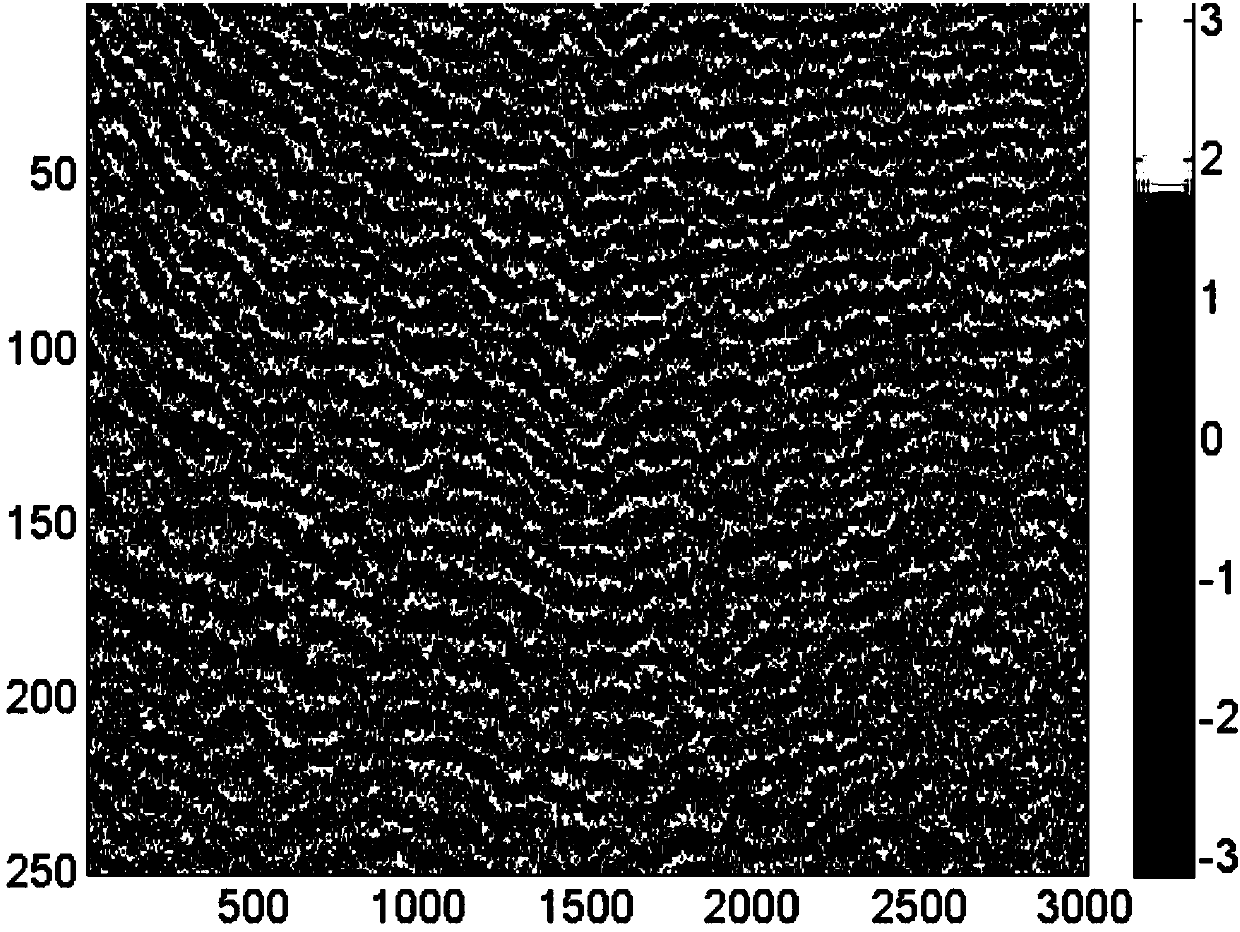

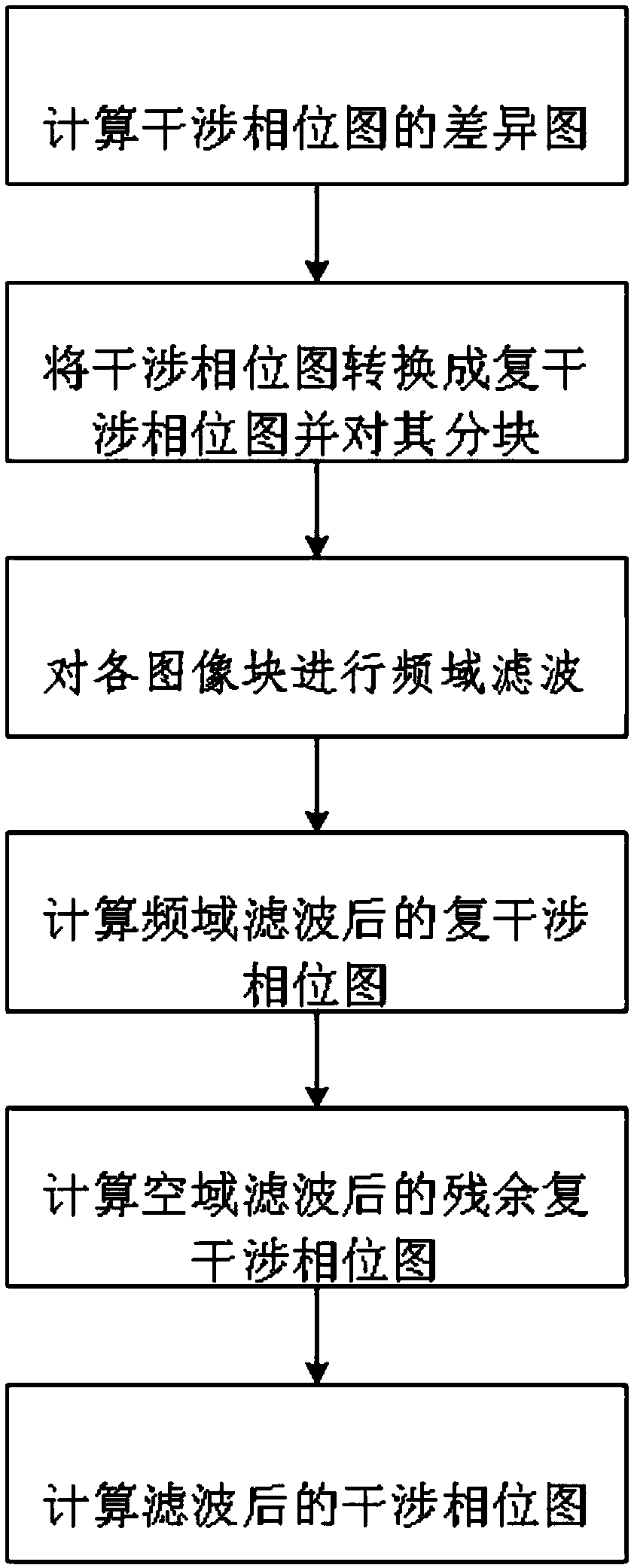

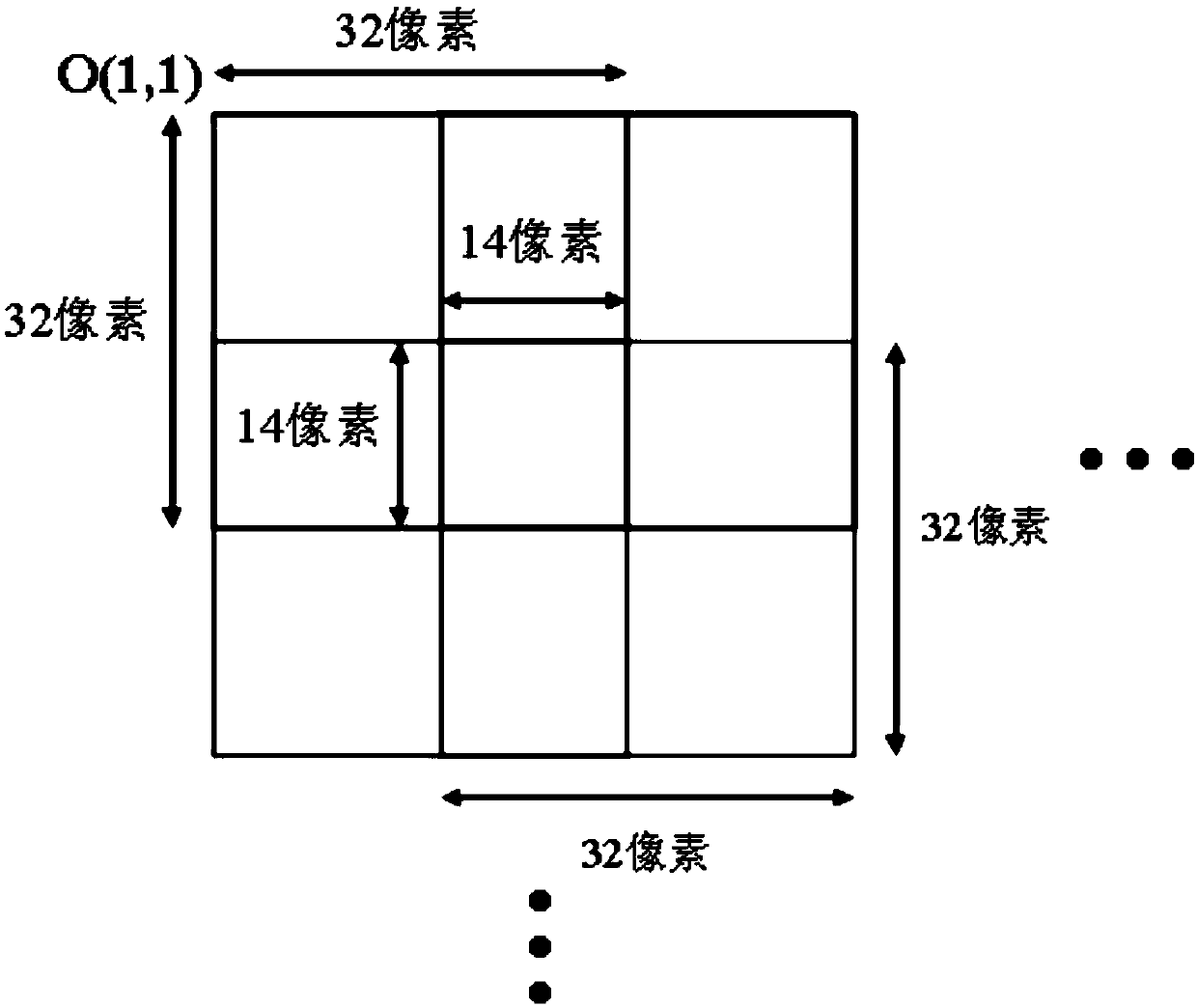

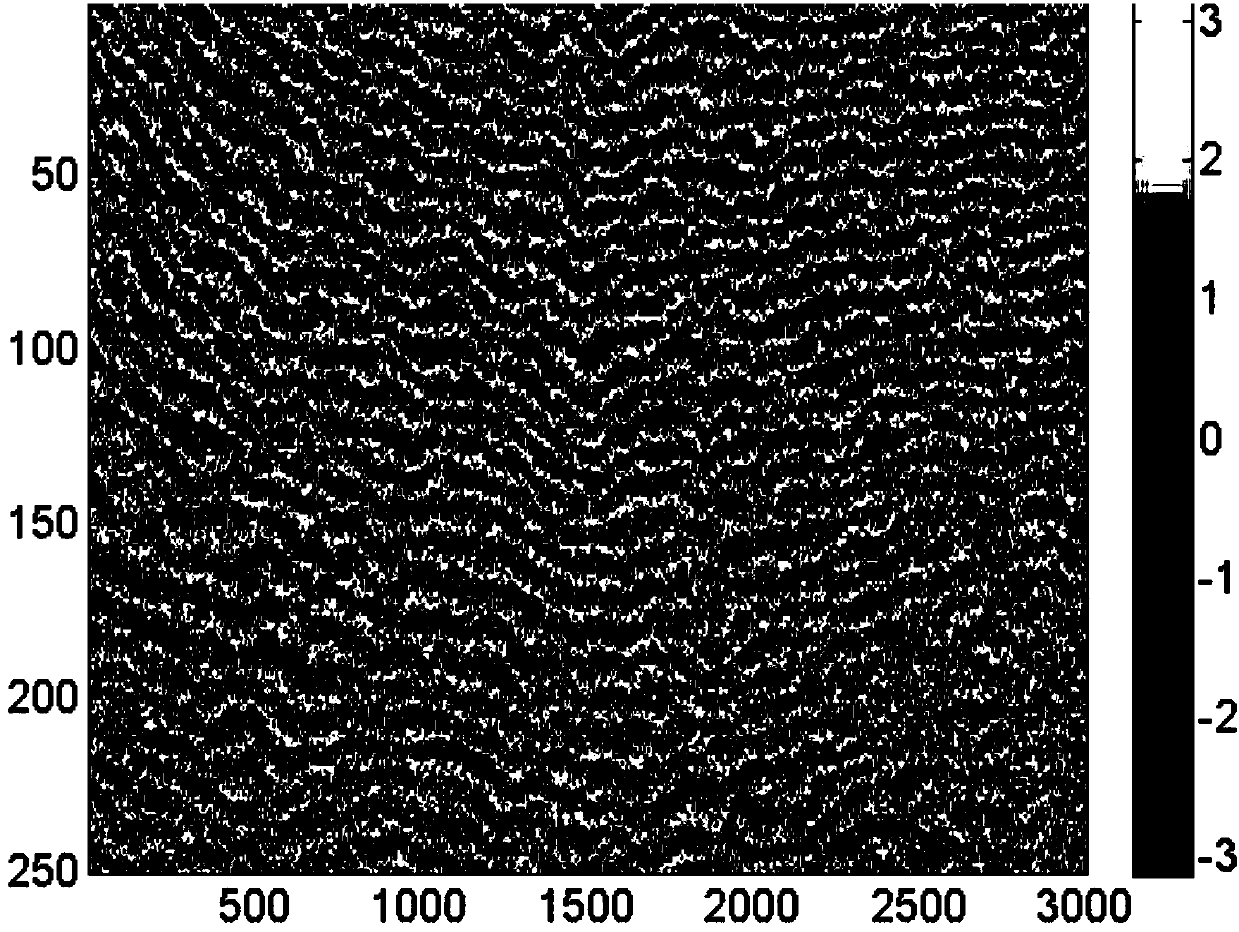

Interferometric phase filtering method based on difference chart and compensation filtering

ActiveCN108090878ALow densityGuaranteed continuityImage enhancementImage analysisPattern recognitionDifference-map algorithm

The invention provides an interferometric phase filtering method based on a difference chart and compensation filtering. The interferometric phase filtering method comprises the steps of: firstly, extracting principal components of interferometric phases from an input interferometric phase image through frequency domain filtering based on the differential chart, so as to reduce density of interferometric fringes in the residual interferometric phase image and facilitate subsequent processing; and secondly, performing compensation filtering on the residual interferometric phase image, wherein compensation filtering adopts BM3D filtering taking a phase derivative variogram of the residual interferometric phase image as self-adaptive filtering parameters, and can better extract detail components of the interferometric phases. The interferometric phase filtering method comprises frequency domain filtering and space domain filtering, is suitable for processing the interferometric phases containing dense interferometric fringes, and can effectively filter out noise without destroying the continuity of the dense interference fringes.

Owner:湖南鼎方量子科技有限公司

A kind of assembly method of thermal aerosol coolant and thermal aerosol generating agent

ActiveCN110755776BIncrease profitImprove cooling efficiencyFire rescueFire extinguisherProcess engineeringExothermic reaction

Owner:SHAANXI LUFANG SAFETY TECH

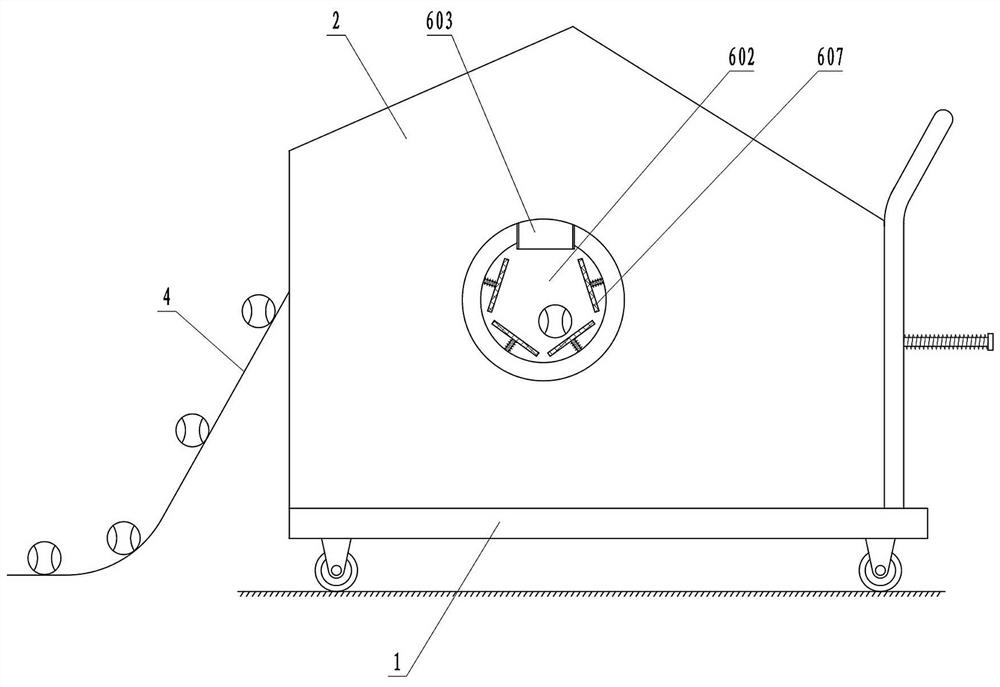

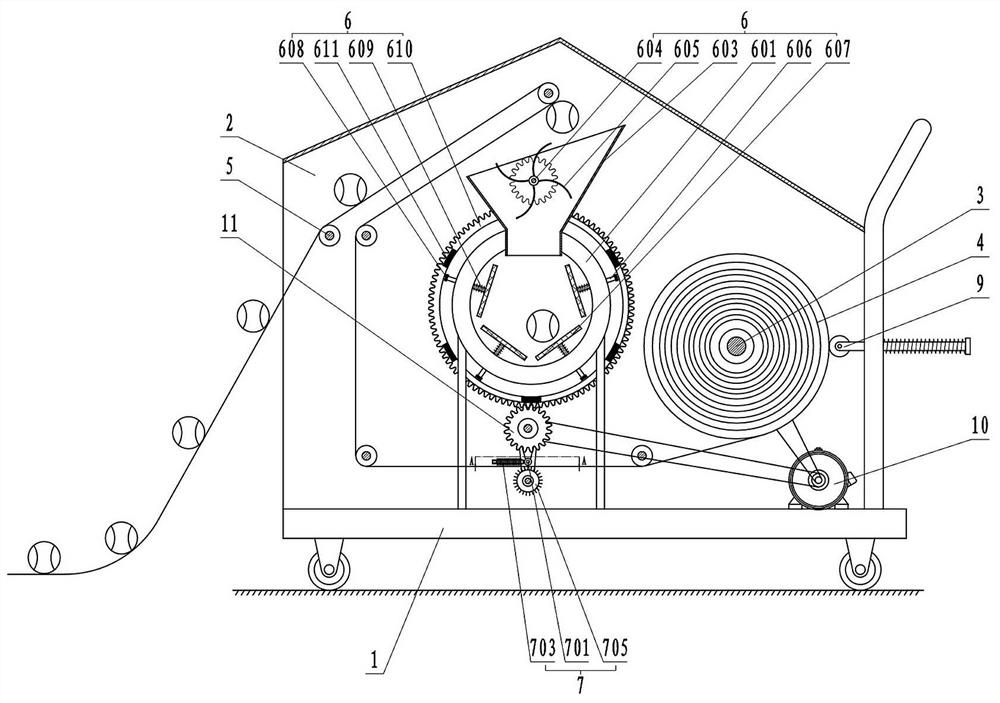

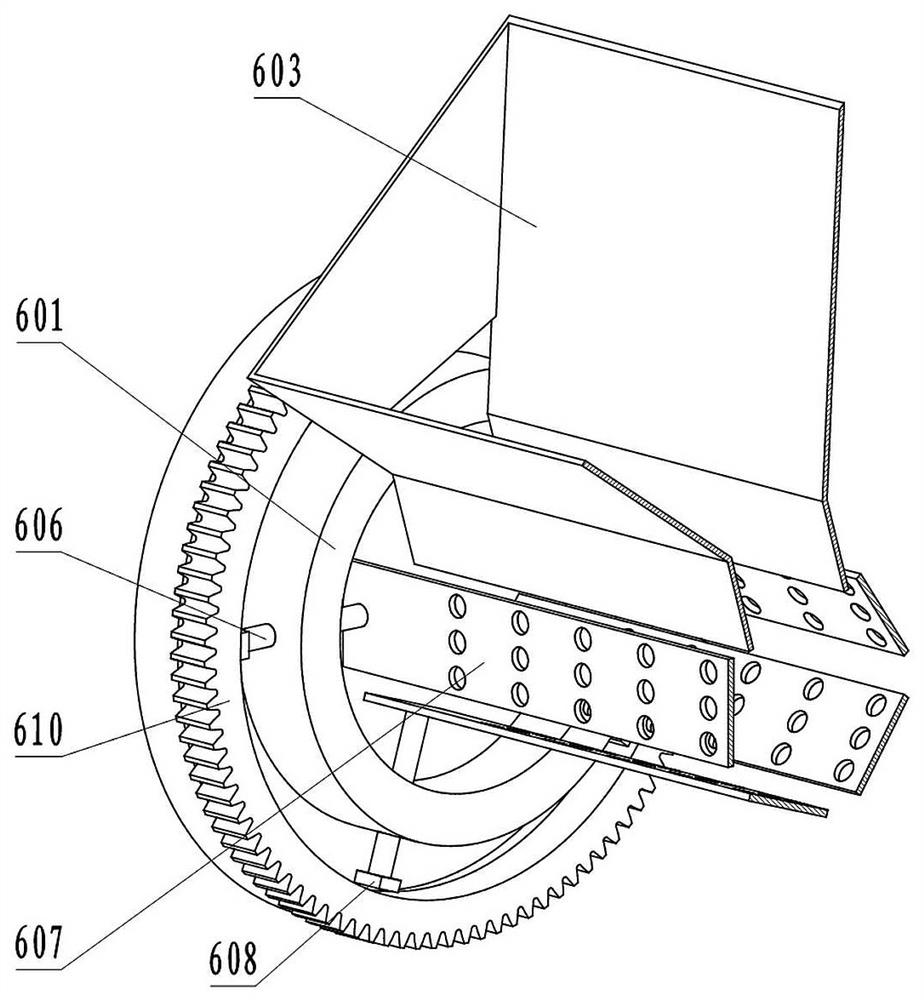

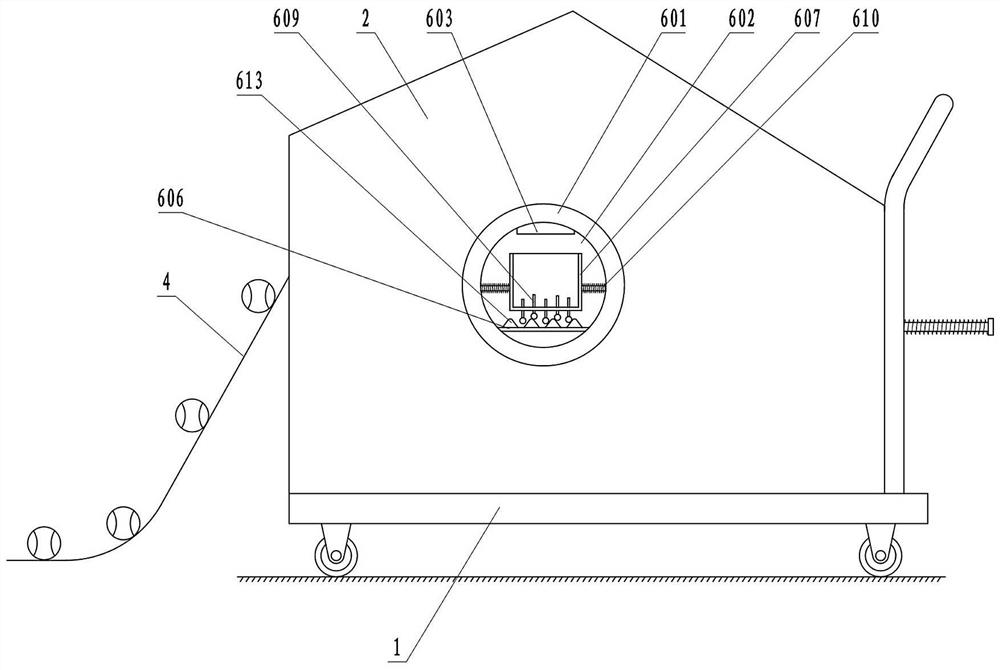

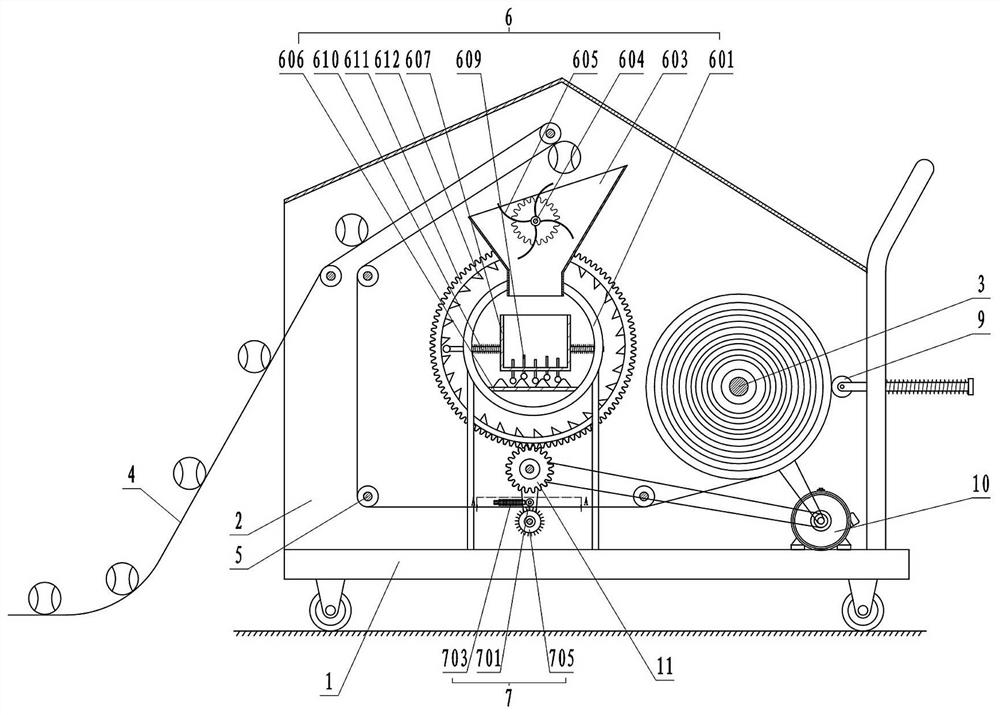

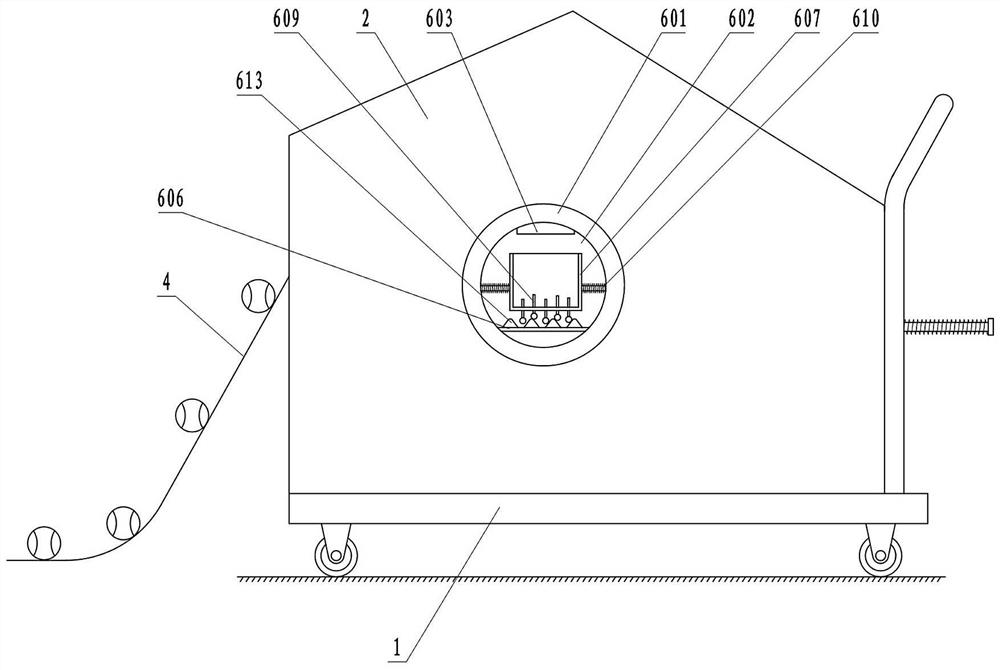

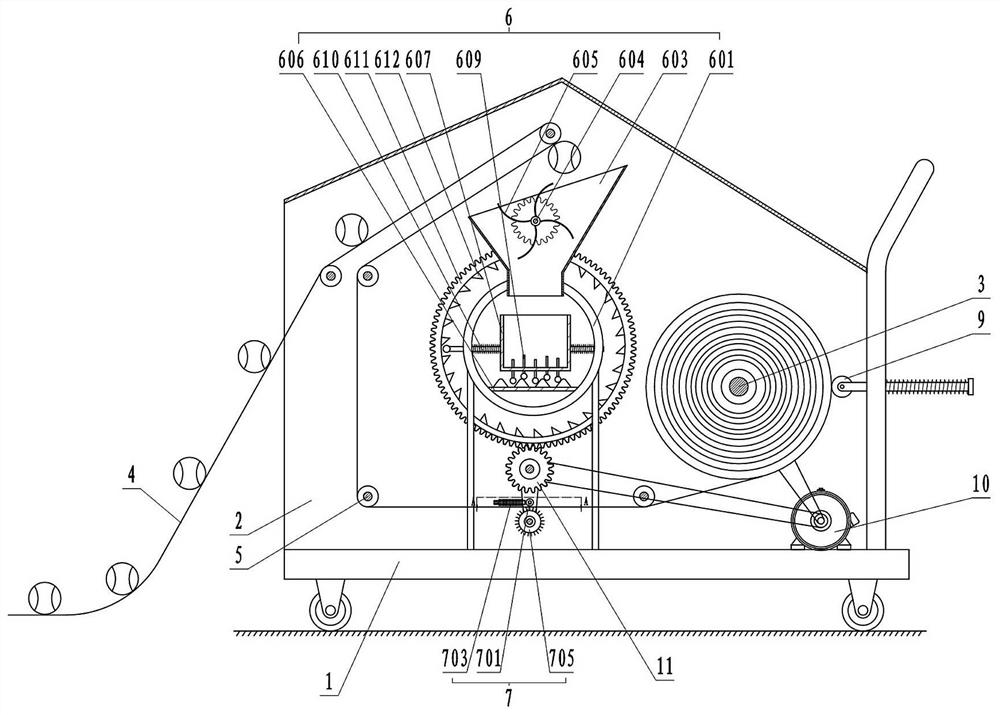

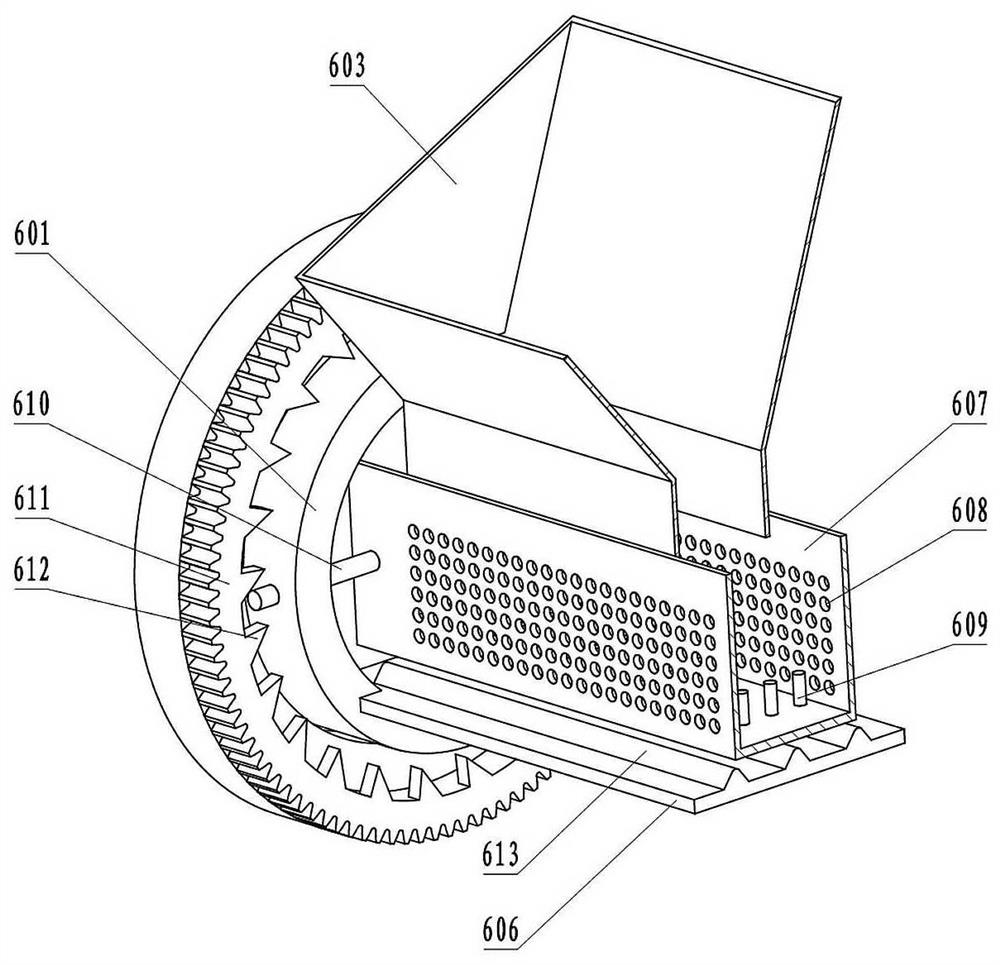

Tennis ball picking and cleaning device

PendingCN112642121AImprove work efficiencyDoes not break continuityBall sportsBack-up ringTennis ball

The invention relates to a tennis ball picking and cleaning device, and effectively solves the problems that: tennis balls near a blocking net are inconvenient to pick, and meanwhile training is affected by ball picking. According to the technical scheme, the device comprises a platform lorry, a front side plate and a rear side plate are arranged on the platform lorry, a reel is arranged between the two side plates, a conveying belt is arranged on the reel, and hook-and-loop fasteners are arranged on the conveying belt; a ball receiving device is arranged between the two side plates; the ball receiving device comprises two supporting rings fixed to the front side plate and the rear side plate, and meanwhile a ball outlet corresponding to a supporting ring are formed in the front side plate; a ball receiving hopper is arranged between the two supporting rings, a rotating shaft in the front-back direction is installed in the ball receiving hopper, and a plurality of ball shifting pieces are evenly distributed on the circumference of the rotating shaft; and a plurality of radial supporting rods are installed on each supporting ring, the supporting rods can reciprocate in the radial direction of the supporting rings and reset outwards, flapping plates are fixed between the two supporting rods corresponding front and back, a gap is reserved between every two adjacent flapping plates, and the multiple flapping plates surround the lower portion of the ball receiving hopper. The tennis ball picking and cleaning device can perform unfelt ball picking and ball cleaning.

Owner:郑州大学体育学院

Composite material for electric heating and overheat protection and preparation thereof

InactiveCN100400583CGood PTC performanceDoes not break continuityNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsCarbon nanotubeRoom temperature

This invention discloses a kind of composite materials for electroheating and thermal-overload protection, which comprises 4~7wt% carbon nanotubes and 96~93wt% high-density polyethylene. In this invention, melting blending is adopted and the steps are as follows: carbon nanotube powders and high-density polyethylene particles are weighed according to the ratio above and put into a mould after mixing to homogeneity at a temperature of 140~170 deg. C. The mixture is first preheated at a temperature of 165~180 deg. C for 5~20 minutes and compressed under a pressure of 5~20MPa and 10~30MPa for 5~20 minutes, respectively. It is then demoulded and cooled to room temperature. The composite materials in this invention adopt high-density polyethylene as matrix and carbon nanotubes as additives and have the advantages of lower additive amount compared to carbon black and no damnification to matrix continuity. This kind of materials has good PTC properties which promise both electroheating and thermal-overload protection functions and self-limited temperatures. Besides, this invention also has the advantages of simple technique, easy operation and considerable repeatability and is thus suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

Tennis ball collection device

ActiveCN112774147BImprove work efficiencyDoes not break continuityBall sportsStructural engineeringConveyor belt

Owner:山东沂南园区开发建设有限公司

A 3D printing method for metal samples containing built-in inclusions

ActiveCN105598449BAccurate locationHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMolten bath

The invention discloses a 3D printing forming method of a metal sample containing built-in inclusions, which comprises the following steps: modeling the three-dimensional model of the metal sample and obtaining its layer profile data; using a laser cladding forming method with the help of a high-energy laser beam A molten pool is formed on the metal plate; the powder of the metal sample is used as the base material, which is transported into the molten pool through the powder feeding device and the powder nozzle for melting, and the current layer is printed out, and clad layer by layer to the designated position of the inclusion; The inclusions whose shape and composition are known are fixed at the designated position, and continue to be clad and formed layer by layer to the height required by the metal sample. The invention adopts the laser cladding forming technology, and puts the inclusions with known shapes into the metal matrix during cladding. The method of the present invention can not only prepare metal samples of various complex shapes, but also ensure that the specific position and original shape of the inclusions can be accurately located without destroying the continuity of the metal matrix, which improves the research efficiency of the inclusions in the metal. Precision and accuracy.

Owner:YANSHAN UNIV

Sealing device

The invention discloses a sealing device which comprises a power input shaft, a casing, a shaft sleeve, a spring base, a push ring, a compensation ring base, a dynamic ring, a static ring, a fastening screw, a spring, a transmission screw, a transmission pin and sealing rings. The power input shaft penetrates through the casing and is arranged in the casing, a shaft sleeve is sleeved outside the power input shaft, a spring base, the push ring, the compensation ring base, the dynamic ring and the static ring are sequentially arranged outside the shaft sleeve, the static ring is arranged to be close to an end of the casing, the spring base is fixed on the shaft sleeve through the fastening screw, the spring and the transmission screw are arranged between the spring base and the push ring, the push ring and the compensation ring base are connected through the transmission pin, one sealing ring is arranged between the static ring and the casing, one sealing ring is arranged between the compensation ring base and the shaft sleeve, and an isolation soft pipe is sleeved outside the spring. Spacer fluid is arranged in the casing. The sealing device can prevent sealing failure caused by solid impurities in a medium in the casing.

Owner:SUZHOU DONGLI MACHINERY

A high-efficiency forging method for fine-grained large-scale die forgings of high-alloy ultra-high-strength steel

ActiveCN104874712BDoes not break continuityImprove pass rateMetal-working apparatusAlloyUltimate tensile strength

The invention belongs to the technical field of forging and relates to a grain refining efficient forging method of high-alloy ultrahigh-strength steel large-scale die-forged parts. The method is used for machining large-scale die-forged parts such as an airplane landing gear and includes the steps of shearing billets, heating, manufacturing billets, heating and die forging. The method has the advantages that the grain refining efficient forging method of the high-alloy ultrahigh-strength steel large-scale die-forged parts is researched for the first time, the forged parts acquire 8-level grains while the production efficiency of the forged parts is 5-8 times of that of conventional forged part production, and noises during production is reduced by more than 30 decibel; the high thermoplasticity of high-alloy high-strength steel is combined with a fast forging machine and a large hydraulic machine, billet manufacturing and die forging heating number deformation amount are reasonably distributed, and the grain refining forging method of the large-scale forged parts is formed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method and device for monitoring seepage of underground diaphragm wall of foundation ditch of building

ActiveCN102691286BDoes not break continuityOmit mechanical testIn situ soil foundationSlurry wallMarking out

Owner:湖南继善高科技有限公司

Tennis ball collecting device for tennis court

The invention relates to a tennis ball collecting device for tennis court, which effectively solves the problems that tennis balls near a blocking net are inconvenient to pick up, and meanwhile ball picking affects training. According to the technical scheme, the device comprises a flat car, two side plates are arranged on the flat car, a reel is arranged between the two side plates, a conveying belt is arranged on the reel, and a hook-and-loop fastener is arranged on the upper end face of the conveying belt; a ball receiving device is arranged between the two side plates and comprises two supporting rings, a ball receiving hopper is fixed between the two supporting rings, a rotating shaft in the front-back direction is installed in the ball receiving hopper, and a plurality of ball shifting pieces are evenly distributed on the circumference of the rotating shaft. A bottom plate is fixed between the front supporting ring and the rear supporting ring, a box body is arranged above the bottom plate, the upper side and the front side of the box body are open, and through holes are formed in the side wall of the box body; the box body can reciprocate left and right; a plurality of vertical guide rods are installed at the bottom of the box body, and the guide rods can move up and down and reset downwards. The left-right movement of the box body can drive the multiple guide rods to move up and down, and non-inductive ball picking and cleaning are achieved.

Owner:山东沂南园区开发建设有限公司

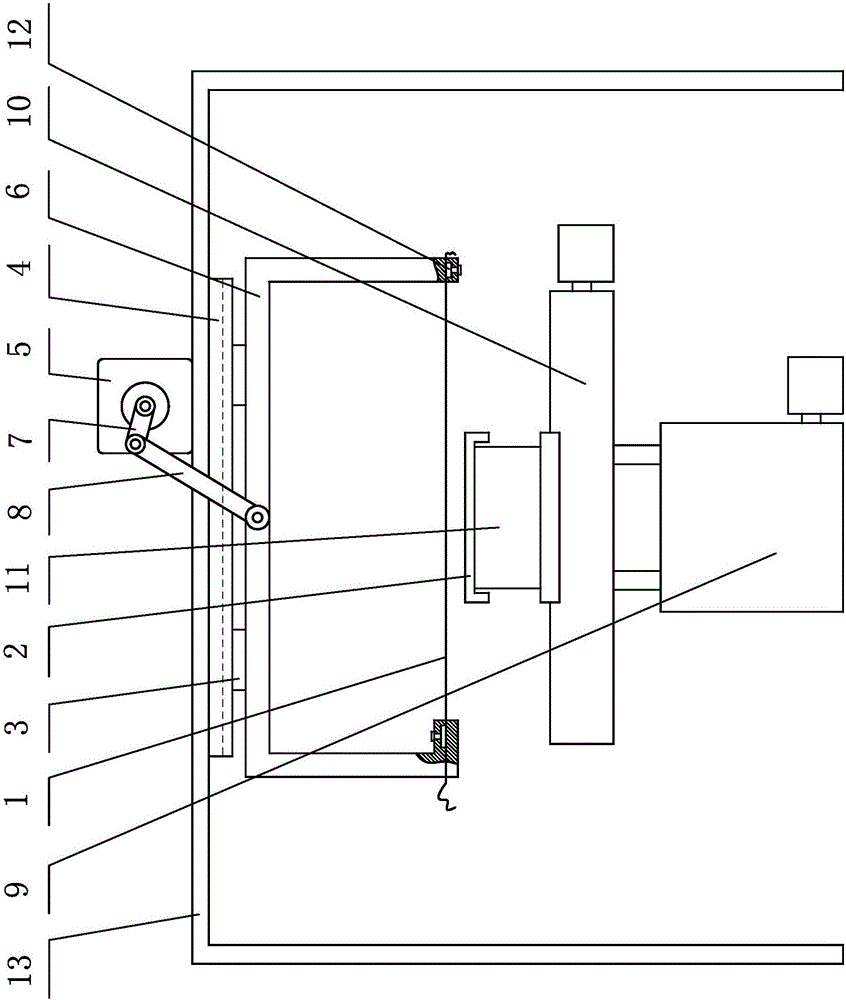

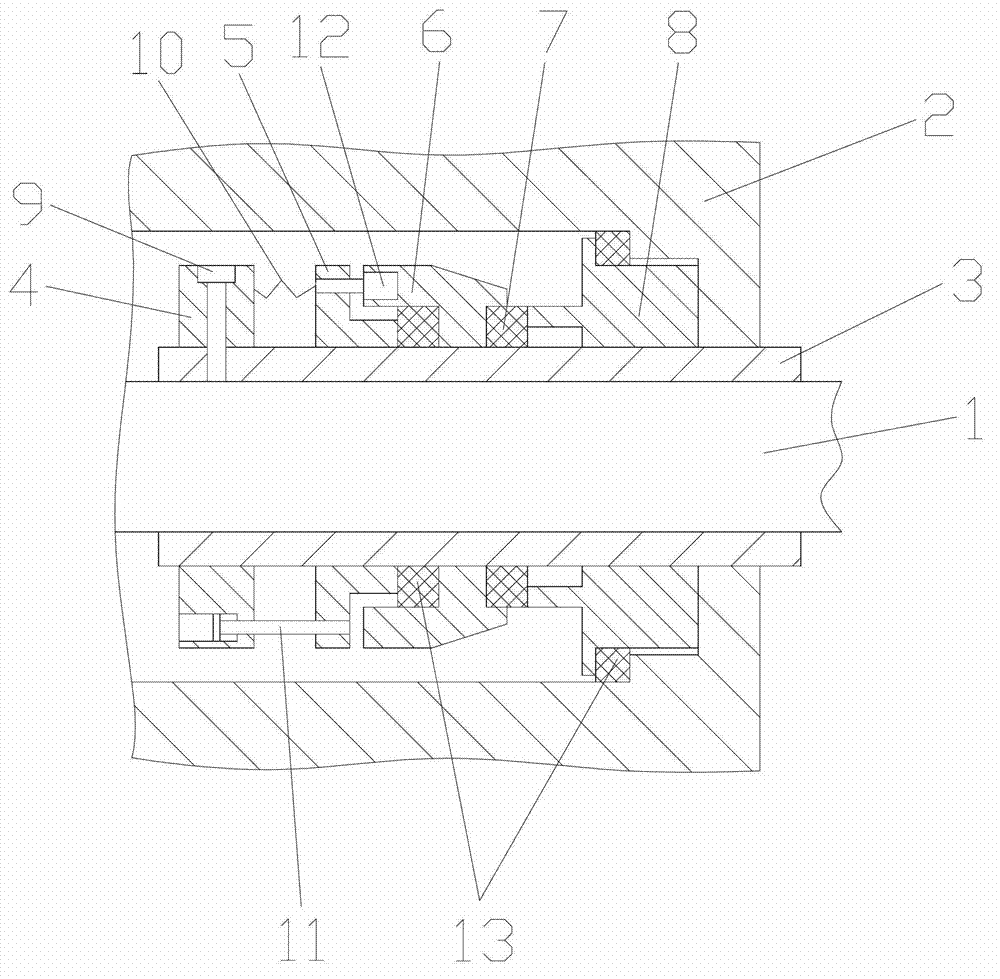

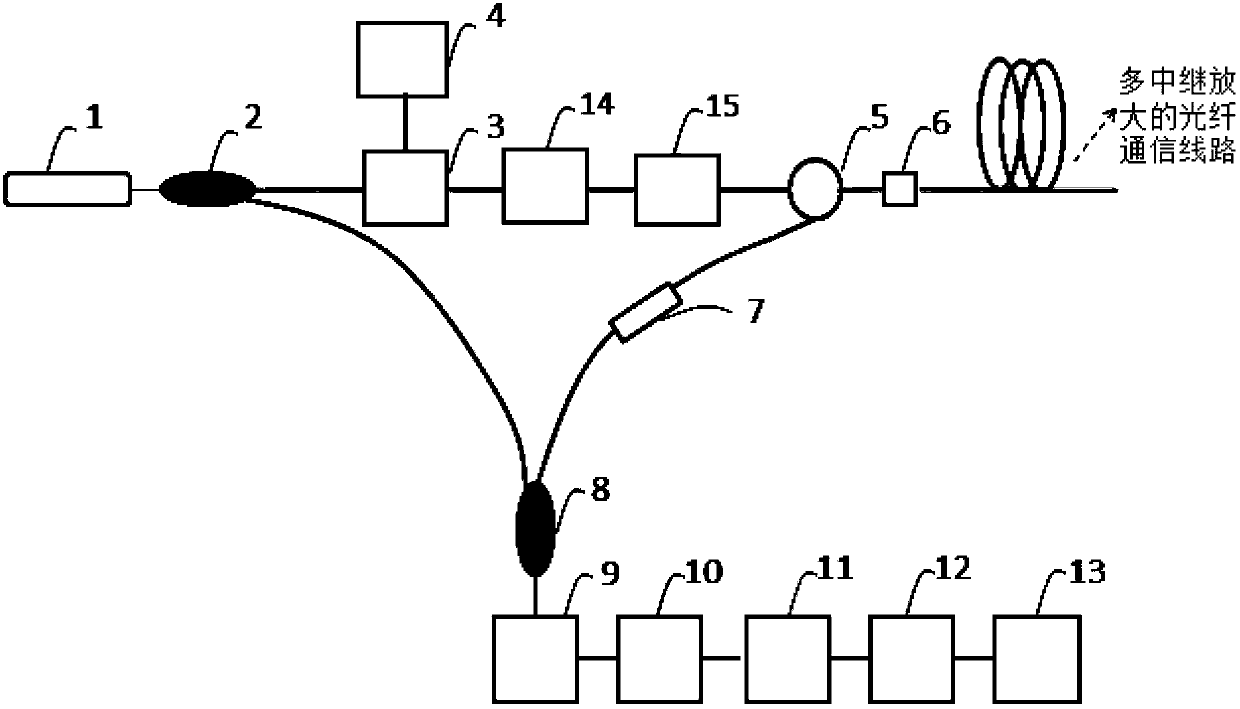

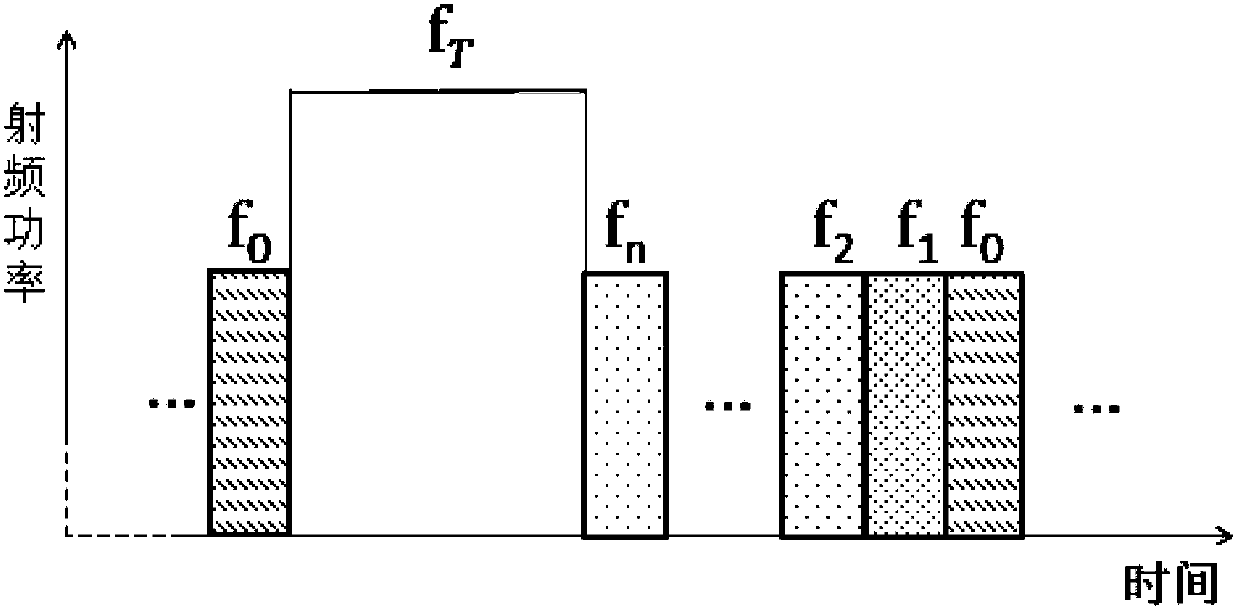

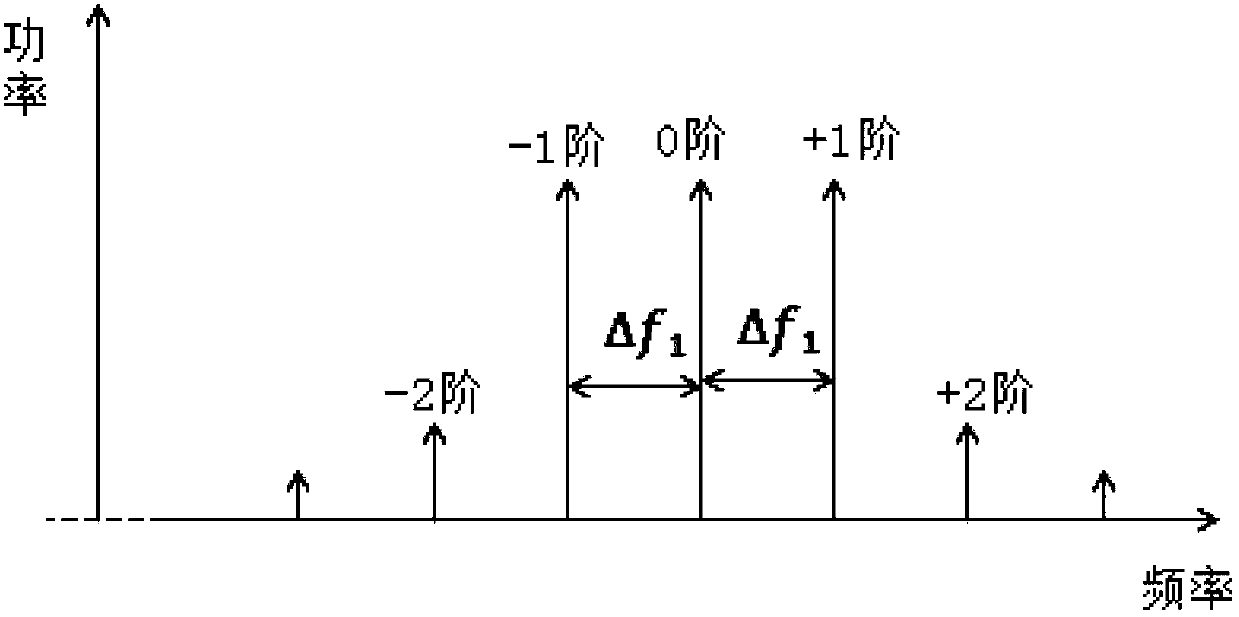

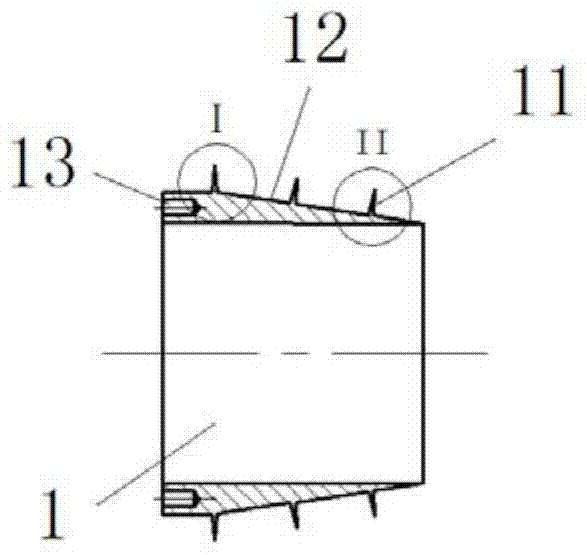

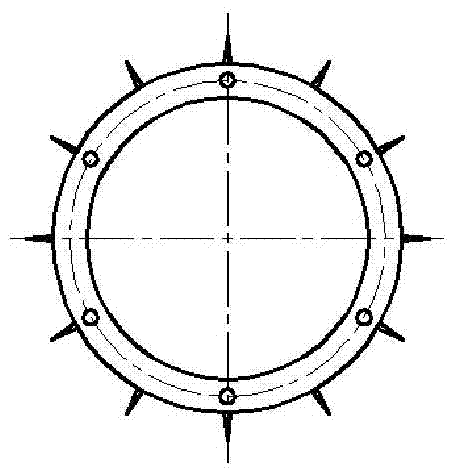

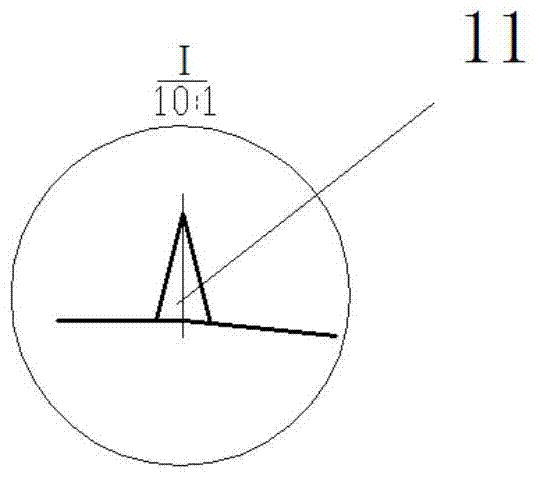

A Coherent Optical Time Domain Reflectometer Based on Detection Frequency Coding

ActiveCN103401606BDoes not break continuityRaise the Brillouin ThresholdElectromagnetic transmissionReflectometers detecting back-scattered light in time-domainRayleigh scatteringTime-domain reflectometer

A coherent optical time domain reflectometry coded based on a detection frequency comprises a laser (1), a first coupler (2), a frequency coder (3), a radio frequency driver (4), a circulator (5), an optical interface (6), a light filter (7), a second coupler (8), a photoelectric detector (9), an intermediate frequency amplifier (10), a data acquisition module (11), a signal processing module (12), and a display module (13). A laser beam emitted by the laser (1) is frequency-coded by the frequency coder (3) to obtain detection frequency pulsed light and a filled light pulse sequentially complementary to the detection frequency pulsed light. The detection frequency pulsed light and the filled light pulse are different in frequency, and after their backward Rayleigh scattered signals in an optical fiber line are returned, the signals enter the light filter (7) through a third port; a detection optical signal and local oscillation light that are obtained after the filtering are coherent in the second coupler (8), and then the photoelectric detector (9) outputs a coherent intermediate frequency signal; and finally, the intermediate frequency signal is collected and processed to obtain a timing curve reflecting characteristics of the optical fiber line.

Owner:STATE GRID CORP OF CHINA +5

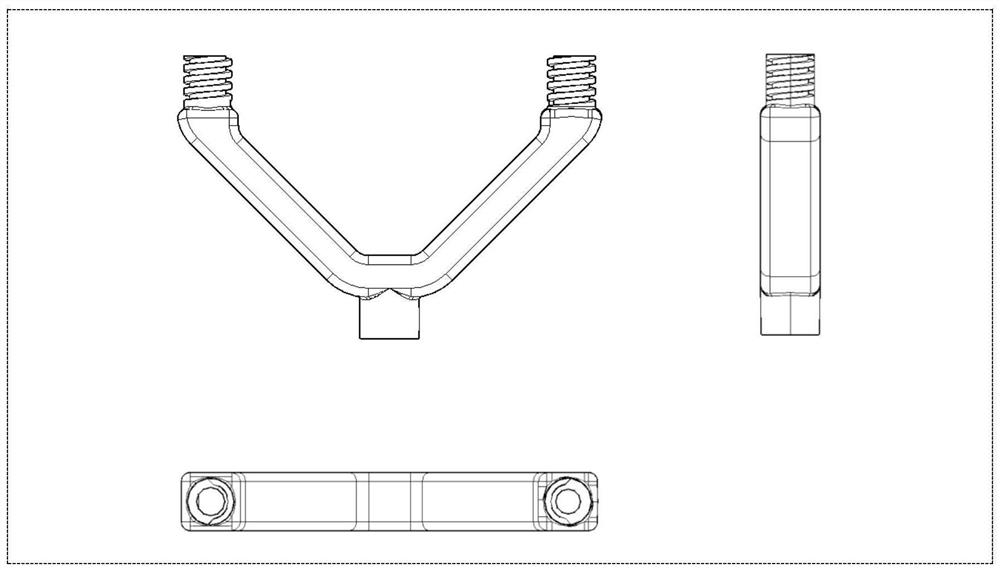

A z-pin connection method for carbon fiber composite transmission shaft and metal flange

InactiveCN105333021BDoes not break continuityImprove performanceCouplings for rigid shaftsDrive shaftCoupling

The invention relates to a Z-pin connecting method for a carbon fiber composite transmission shaft and a metal flange. The Z-pin connecting method specifically comprises the following steps: a transitional part, namely a Z-pin sleeve (1), is additionally arranged at the connecting part of the carbon fiber composite transmission shaft (4) and the metal flange (5), and the carbon fiber composite transmission shaft (4) and the Z-pin sleeve (1) are integrated in a fiber winding manner and are solidified together. The Z-pin connecting method provided by the invention can realize reliable connection between the carbon fiber composite transmission shaft and the metal flange; during the working process of the carbon fiber composite transmission shaft, the carbon fiber composite transmission shaft (4) transmits load to the Z-pin sleeve (1), and the Z-pin sleeve (1) transmits load to the metal flange (5) through a pin (6), so that the bearing capacity of the connecting part of the carbon fiber composite transmission shaft and the metal flange is greatly improved, and the carbon fiber property is brought to full play. The Z-pin connecting method is high in practicality and can promote application of the carbon fiber composite in the industries of automobiles, machine tools and the like.

Owner:WUHAN UNIV OF TECH

Interferometric Phase Filtering Method Based on Difference Map and Compensation Filtering

ActiveCN108090878BDoes not break continuityEffective filteringImage enhancementImage analysisPattern recognitionDifference-map algorithm

Owner:湖南鼎方量子科技有限公司

Electric heating composite material for temperature measurement and preparation method thereof

InactiveCN100439886CSimple processEasy to operateThermometers using electric/magnetic elementsUsing electrical meansElectricityHigh density

The invention discloses an electrical heating compound material for measuring temperature, which comprises 6~9% weight percentage multi-walled carbon nanotubes, 91~94% weight percentage high density polyethylene. The method for making the compound material comprises: weighing multi-walled carbon nanotubes powder and high density polyethylene in proportion; mixing them and placing them into a model; pre-heating 5~20 minutes in 165~180 centigrade, pressing 5~20 minutes under 5~30 MPa pressure; stripping membrane and cooling to room temperature. The inventive compound material takes high density polyethylene as base, multi-walled carbon nanotubes as additive, which make the compound material has great conductivity and electrical heating performance and be used to temperature measurement in a certain temperature range.

Owner:ZHEJIANG UNIV

Barrier coating material for food paper and paperboard, food paper and paperboard

InactiveCN113969519ALow solubility parameterImprove securityFlexible coversWrappersPolymer sciencePaperboard

In order to solve the problems that an existing polyacrylate coating for food paper and paperboard is insufficient in water and oil barrier performance and prone to adhesion, the invention provides a barrier coating material for food paper and paperboard, food paper and paperboard. The barrier coating material comprises the following components: a component A: acrylate copolymer emulsion, wherein the average particle size of emulsion particles is 0.02-0.2 micron, and the Tg value is -20-10 DEG C; a component B: acrylate copolymer emulsion, wherein the average particle size of emulsion particles is 0.02-0.2 micron, and the Tg value is 10-120 DEG C; and a component C: a non-crosslinked polymer emulsion, wherein the average particle size of emulsion particles is 0.5-5 microns, and the Tg value is 75-120 DEG C. The barrier coating material for the food paper and the paperboard, provided by the invention, has relatively good anti-adhesion performance while the water and oil barrier capability and the heat sealability are ensured.

Owner:GUANGZHOU HUMAN CHEM

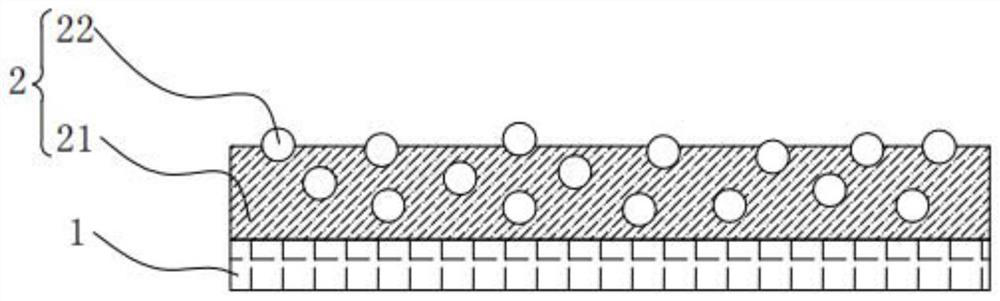

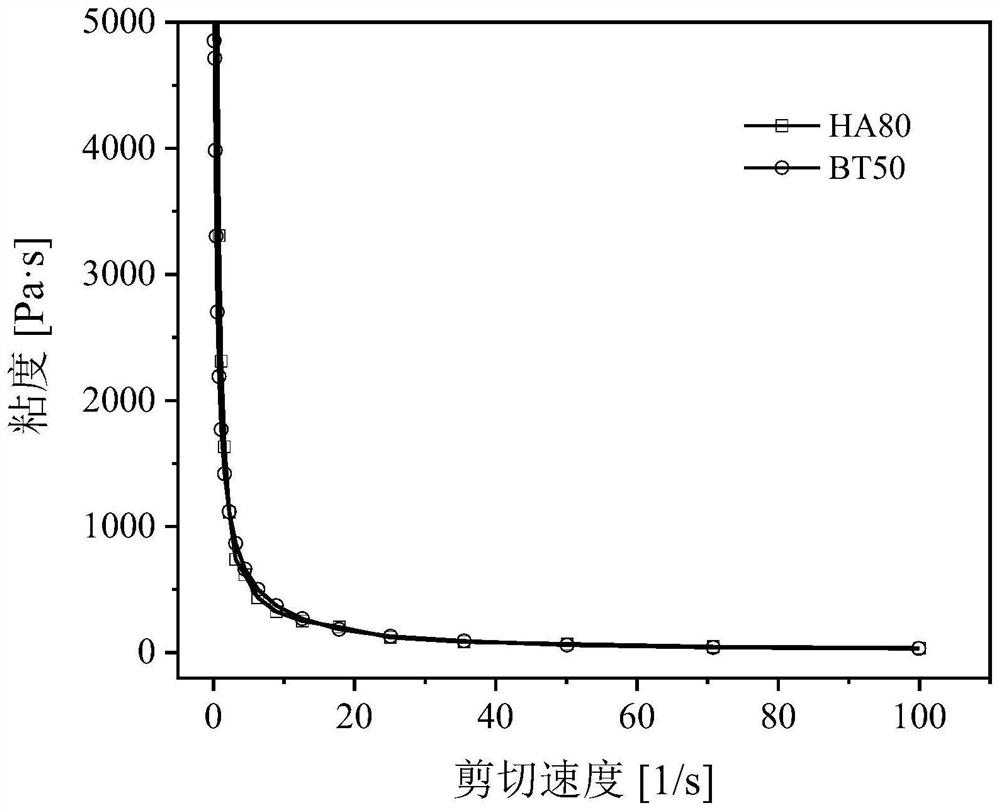

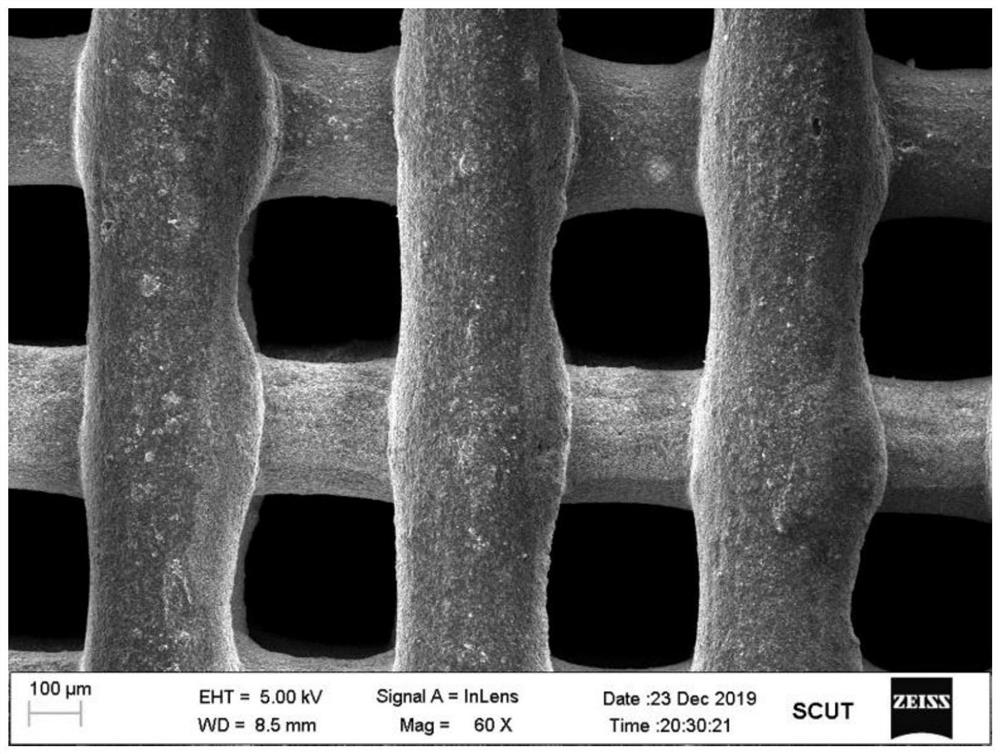

A novel bt/ha biphasic piezoelectric bioceramic bone tissue engineering restoration and its preparation method

ActiveCN112457003BFree adjustment contentDoes not break continuityAdditive manufacturing apparatusTissue regenerationFiberComputer printing

The invention discloses a novel BT / HA biphase piezoelectric bioceramics bone tissue engineering prosthesis and a preparation method thereof. The method includes: separately preparing BT and HA slurries; designing a communication device to connect two printing barrels; printing piezoelectric bioceramics with a melt extrusion 3D printer (FDM) that can simultaneously print multiple barrels Bone tissue engineering scaffold; the printed scaffold is dried and sintered at high temperature in an air atmosphere to obtain a piezoelectric bioceramic scaffold. The beneficial effects of the present invention are as follows: 1. By using a communication device to connect two barrels containing different slurries, it is ensured that the same fiber extruded by the 3D printer has two continuous phases, which is different from the traditional single barrel. Compared with extrusion printing, a new composite method of two-component materials is created, so that the constructed scaffold has a new structure; 2. The content of HA / BT can be freely adjusted by adjusting the viscosity of the two slurries without destroying Piezoelectric phase continuity.

Owner:SOUTH CHINA UNIV OF TECH

Full-automatic labeller

PendingCN111924249ADoes not break continuityInhibit sheddingLabelling machinesElectric machineryStructural engineering

The invention provides a full-automatic labeller. The full-automatic labeller comprises a main table body, wherein a motor supporting table is fixedly connected to one side of the middle part of the main table body, and a reduction gearbox is fixedly connected to the top end of the motor supporting table; a wheel shaft is fixedly connected to one side of the reduction gearbox, the middle part of the wheel shaft is sleeved with a roller, and the middle part of the roller is sleeved with a material conveying belt; a feeding table fixedly connected with the side of the main table body is arrangedon one side of the material conveying belt, and a control mechanism is fixed to one side of the top of the feeding table; and a labeling mechanism fixedly connected with the other side of the middlepart of the main table body is arranged on the other side of the material conveying belt, and a belt supporting plate is fixedly connected to one side of the middle part of the labeling mechanism andlocated in the middle part of the inner side of the material conveying belt. According to the full-automatic labeler, by arranging the labeling mechanism, a labeling belt can be prevented from fallingoff from a reel, by arranging a discharging table, labeled materials can be stored, and by arranging a high-precision distance measuring sensor, the situation of miss labelling due to the materials are misjudged is prevented.

Owner:河南合众标识科技有限公司

A coaxial radio frequency cable penetration seal

InactiveCN105633701BTo achieve the two requirements of sealingGuaranteed signal transmission performanceCouplings bases/casesCable junctionsUltrasound attenuationElectrical conductor

The invention provides a coaxial radio frequency cable run-through sealing part. The sealing part comprises a circular adhesive pouring cylinder, a cable fixing board, an isolation assembly and cables, wherein more than two cable fixing holes for fixing and sealing cables are formed in the cable fixing board; the cable runs through the cable fixing holes and the adhesive pouring cylinder to enter a sealed container; the outer sheath on one section, in the middle of the adhesive pouring cylinder, of the corresponding cable is peeled off to form an adhesive permeating section; the exterior of the adhesive permeating section is surrounded by the isolation assembly; an adhesive inlet hole is formed in the isolation assembly; one end of the adhesive pouring cylinder is connected with the cable fixing board through a second flange; and the adhesive pouring cylinder is full of liquid sealant for sealing and blocking slot leakage among cables and the internal slot leakage of cable external conductors. According to the coaxial radio frequency cable run-through sealing part, the problem existing in sealing multiple cables led out of the sealed container is solved; meanwhile, the cable inner sealing and cable outer sealing are realized; and therefore, the coaxial radio frequency cable run-through sealing part has the advantages of no extra attenuation in signal transmission, simple structure, and reliable sealing performance.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

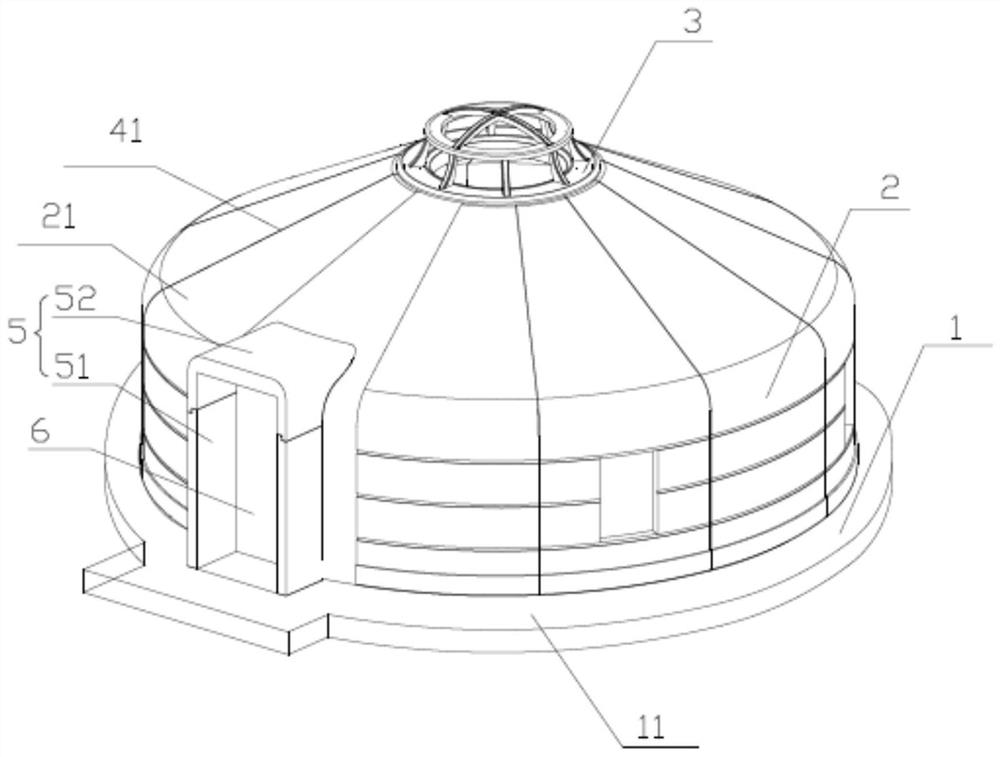

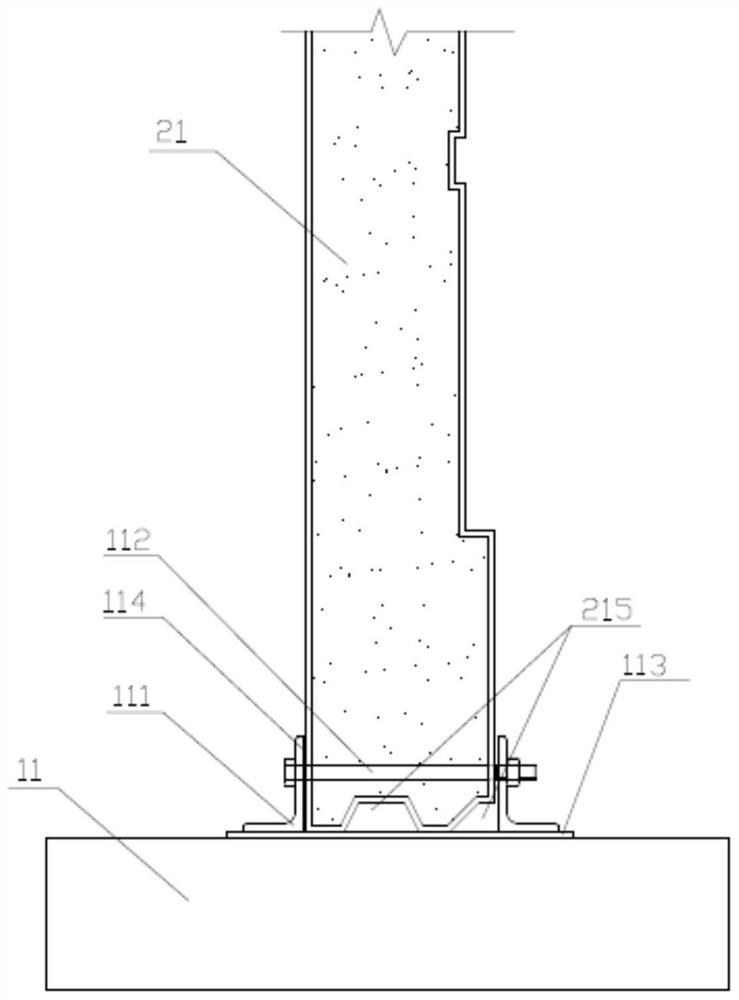

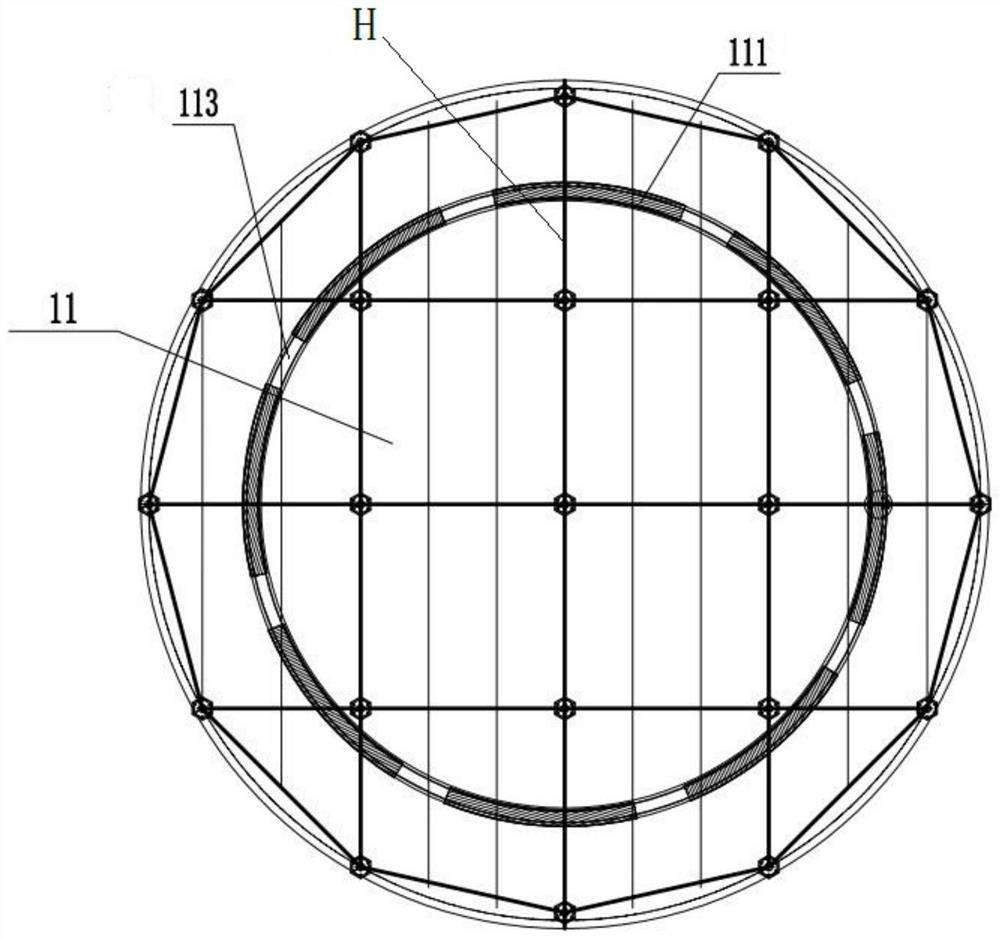

Fabricated yurt structure and construction method thereof

PendingCN114775836AReduce labor intensityNo pollution in the processBuilding roofsWallsMechanical engineeringIndustrial engineering

The invention provides a fabricated yurt structure and a construction method thereof. The fabricated Mongolian yurt structure comprises a foundation, a wall body and a ceramic head, and the wall body is defined by a plurality of wall plates to form a Mongolian yurt main body; the wall body is mounted on the foundation, the ceramic head is mounted at the top of the wall body, a plurality of mounting grooves are formed in the foundation, a circle is defined by the mounting grooves, and every two mounting grooves are arranged at intervals; a lower end connecting point is arranged at the bottom of the wall plate, and the lower end connecting point is mounted in the mounting groove; and the lower end connecting point is provided with a vertical concave tongue-and-groove, so that the contact end area of the lower end connecting point and the mounting groove is reduced. The connecting joints between the wallboards are optimized, the connecting joints between the wallboards and the foundation are optimized, and assembly is more convenient and simpler.

Owner:HOHHOT ZHONGDUO XINGTAI YUANDA CONSTR IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com