Graphene-filled polypropylene composite material, and preparation method thereof

A technology of composite material and polypropylene, which is applied in the field of graphene-filled polypropylene composite material and its preparation, can solve the problems of reducing the continuity of polymer collective materials, the conductivity is not as good as graphene, and the strength is destroyed, so as to achieve easy processing and operation The effect of convenience and good PTC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

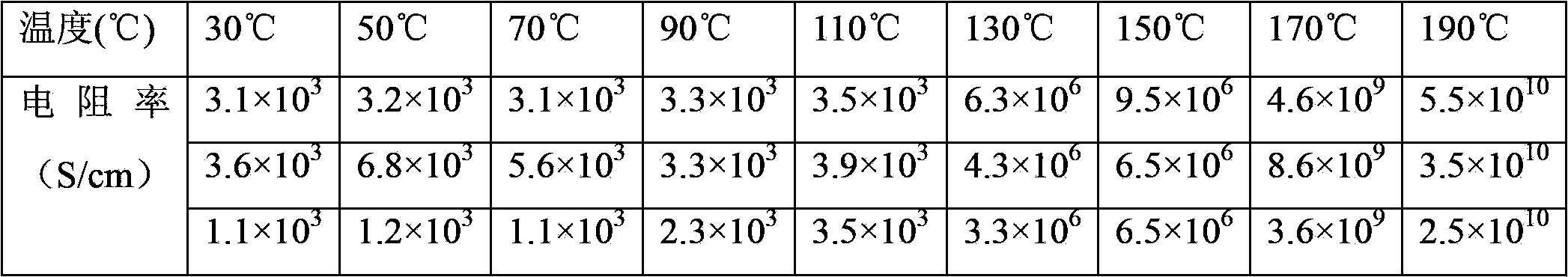

Embodiment 1

[0021] (1) After uniformly mixing 0.5 parts by weight of graphene powder and 99.5 parts by weight of polypropylene (molecular weight: 200,000) masterbatch, put it into a blender and blend at 170°C for 10 minutes;

[0022] (2) Take out the uniformly mixed material and put it into an iron mold, preheat at 185°C for 5 minutes, then press at 5MPa for 5min, and finally press at 10MPa for 10min to obtain a composite material.

Embodiment 2

[0024] (1) Evenly mix 1 part by weight of graphene powder with 99 parts by weight of polypropylene (molecular weight: 200,000) masterbatch, and then blend them in a blender at 180°C for 15 minutes;

[0025] (2) Take out the uniformly mixed material and put it into an iron mold to preheat at 195°C for 10 minutes, then press it at 10MPa for 10 minutes, and finally press it at 20MPa for 15 minutes to obtain a composite material.

Embodiment 3

[0027] (1) After uniformly mixing 2 parts by weight of graphene powder and 98 parts by weight of polypropylene (molecular weight: 300,000) masterbatch, put it into a blender and blend at 190°C for 10 minutes;

[0028] (2) Take out the uniformly mixed material and put it into an iron mold, preheat at 200°C for 5 minutes, then press at 20MPa for 20min, and finally press at 30MPa for 20min to obtain a composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com