Composite material for thermistor and its preparation method and application

A composite material and thermistor technology, applied in the field of composite materials of thermistors, can solve the problems of too fast attenuation of PTC strength and output power, changes in electrical properties of PTC materials, poor stability of PTC effect, etc., and achieve good repeatability. , Improve electrical conductivity, strengthen the effect of current resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

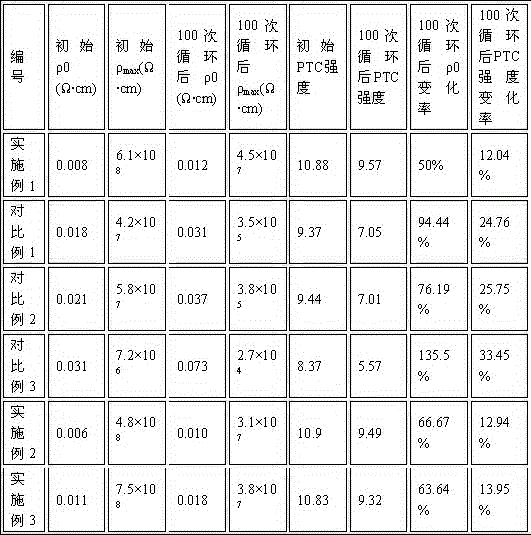

Examples

Embodiment 1

[0034] Add 80 parts by weight of high-density polyethylene and 20 parts by weight of ethylene-vinyl acetate copolymer into the internal mixer, stir and mix for 8 minutes at a speed of 30 rpm and a temperature of 175 ° C; then add 2.5 parts of crosslinking agent triene Propyl isocyanurate, 1.5 parts by weight of antioxidant and 2.5 parts by weight of lubricant continued to mix for 3 minutes to obtain a mixture; 4 parts by weight of carbon fibers and 4 parts by weight of multi-walled carbon nanotubes are subjected to surface treatment, then the treated conductive filler is added to the above mixture, the rotating speed is increased to 80rpm, and then the mixture is continued to be mixed for 3 minutes to obtain the mixture; the above mixture Extrude and granulate with a twin-screw extruder to obtain composite material pellets for thermistors; then mold the above pellets to obtain composite material sheets for thermistors; use 150KGy of electronic Beam radiation, so that the forme...

Embodiment 2

[0044] Add 70 parts by weight of high-density polyethylene and 30 parts by weight of ethylene-vinyl acetate copolymer into the internal mixer, and stir and mix for 6 minutes at a speed of 35 rpm and a temperature of 180 ° C; then add 2 crosslinking agents trihydroxy Methylpropane triacrylate, 1.5 parts by weight of antioxidant and 3 parts by weight of lubricant, continue to mix for 5 minutes to obtain a mixture; respectively use 5,0.5,0.5 parts by weight of coupling agent to 25 parts by weight of titanium diboride, 2.5 parts by weight Parts by weight of carbon fiber and 2.5 parts by weight of multi-walled carbon nanotubes are subjected to surface treatment, then the treated conductive filler is added to the above mixture, the rotating speed is increased to 70rpm, and then the mixture is continued for 3 minutes to obtain the mixture; the above mixture is used After twin-screw extruder extrusion and granulation, the composite material pellets for thermistors are obtained; then th...

Embodiment 3

[0046] Add 75 parts by weight of high-density polyethylene and 25 parts by weight of ethylene-vinyl acetate copolymer into the internal mixer, and stir and mix for 10 minutes at a speed of 40 rpm and a temperature of 170°C; then add 3 crosslinking agents trihydroxy Methylpropane triacrylate, 2 parts by weight of antioxidant and 2 parts by weight of lubricant, continue to mix for 5 minutes to obtain a mixture; respectively use 3.5, 0.6, 0.4 parts by weight of coupling agent to 15 parts by weight of titanium diboride, 3 parts by weight Parts by weight of carbon fibers and 2 parts by weight of multi-walled carbon nanotubes are subjected to surface treatment, then the treated conductive filler is added to the above mixture, the rotating speed is increased to 70rpm, and then the mixture is continued for 3 minutes to obtain the mixture; the above mixture is used After twin-screw extruder extrusion and granulation, the composite material pellets for thermistors are obtained; the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com