Composite material for electric heating and overheat protection and preparation thereof

A technology of overheating protection and composite materials, applied in the direction of resistors with positive temperature coefficient and resistors with negative temperature coefficient, etc., can solve the problems of large addition amount, poor conductivity of carbon black, performance degradation, etc., and achieve good PTC performance , simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

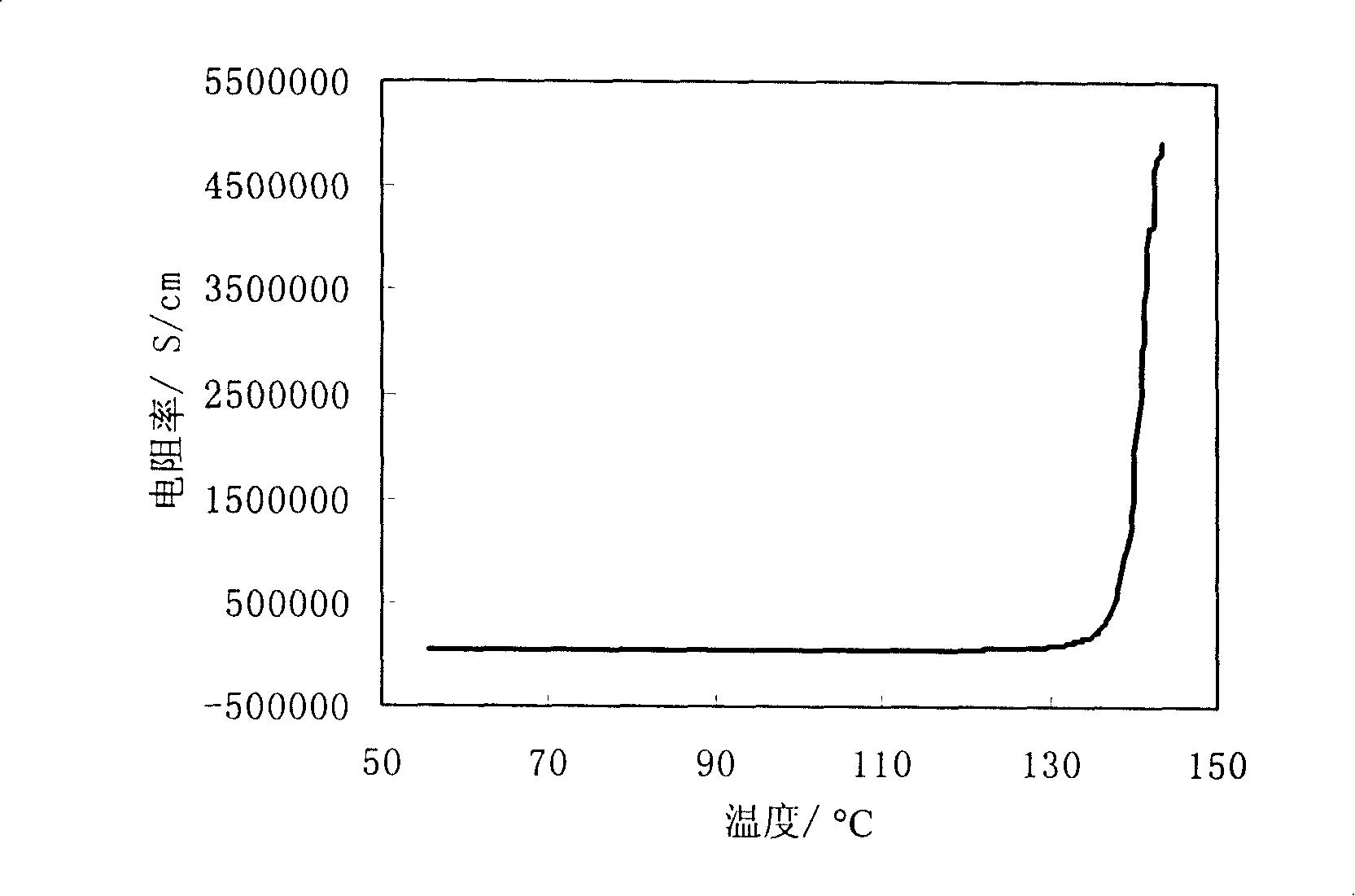

[0016] 2 grams of carbon nanotube powder and 98 grams of high-density polyethylene (molecular weight: 80,000) particles were uniformly mixed, and then put into a blender and blended at 150° C. for 10 minutes. Take out the uniformly mixed material and put it into a copper mold, preheat at 160°C for 5 minutes, then press at 5MPa for 5 minutes, and finally press at 10MPa for 10 minutes to obtain a composite material. figure 1 is the result of the resistivity of the composite material as a function of temperature. When the temperature is lower than 135°C, the composite material is a conductor, and the resistance of the material remains basically unchanged. When the temperature reaches above 140°C, the resistivity of the composite material increases sharply, changing from a conductor to an insulator. It can be seen that the composite material of the present invention has a good PTC effect and can be used as an electric heating and power-off protection material.

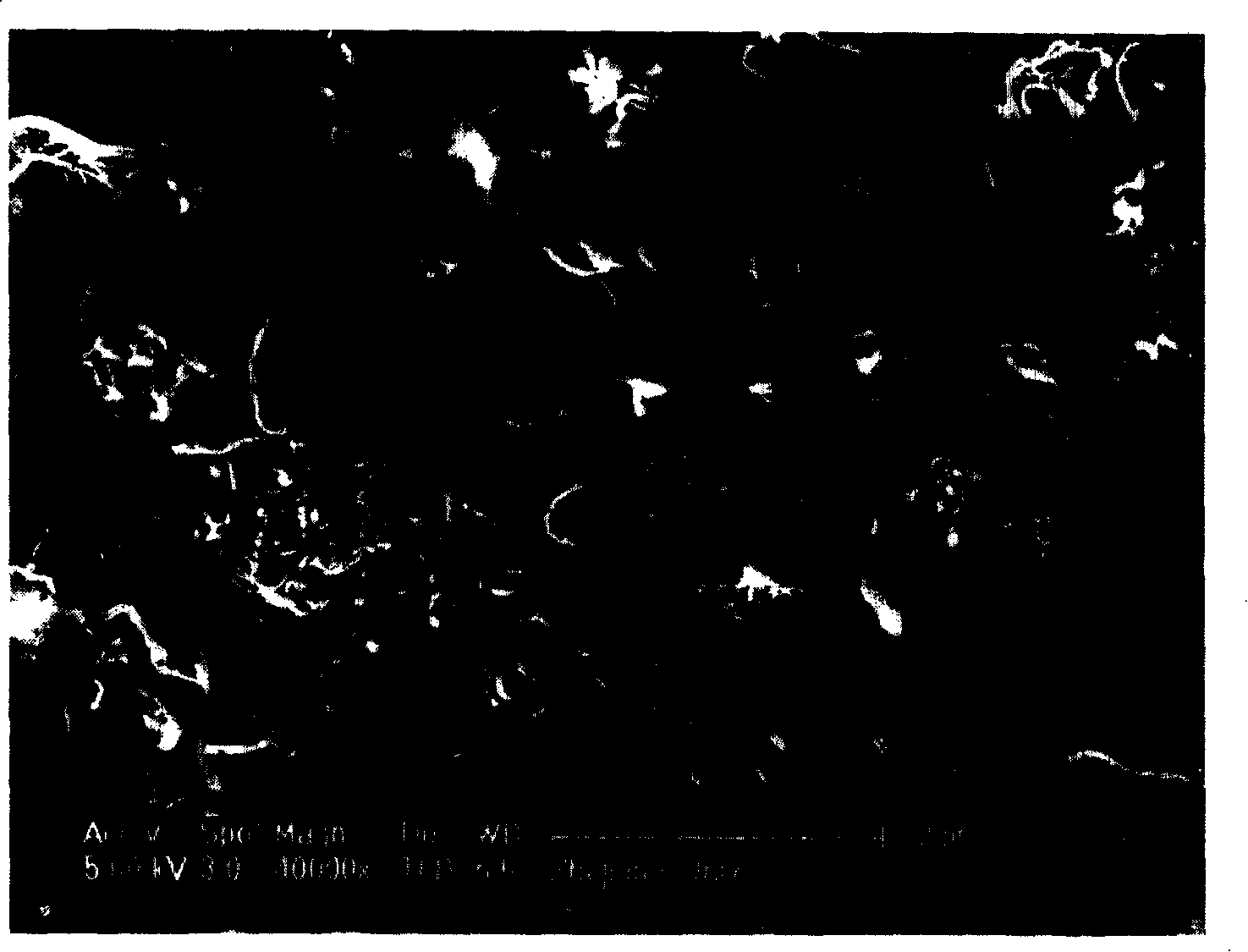

[0017] figure 2...

Embodiment 2

[0019] 3 g of carbon nanotube powder and 97 g of high-density polyethylene (molecular weight: 80,000) particles were evenly mixed, and then put into a blender for blending at 160° C. for 15 minutes. Take out the homogeneously mixed material and put it into a copper mold to preheat at 170°C for 10 minutes, then press at 5MPa for 5 minutes, and finally press at 10MPa for 10 minutes to obtain a composite material.

Embodiment 3

[0021] After 5 grams of carbon nanotube powder and 95 grams of high-density polyethylene (molecular weight: 100,000) particles were evenly mixed, they were put into a blender and blended at 165° C. for 10 minutes. Take out the uniformly mixed material and put it into a copper mold to preheat at 180°C for 5 minutes, then press at 5MPa for 10 minutes, and finally press at 10MPa for 10 minutes to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com