A z-pin connection method for carbon fiber composite transmission shaft and metal flange

A composite material and z-pin technology, applied in the direction of rigid shaft couplings, couplings, mechanical equipment, etc., can solve the problems of complex process and inability to fully exert the excellent performance of carbon fiber, and achieve simple winding process and low manufacturing cost Low, the effect of improving the load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

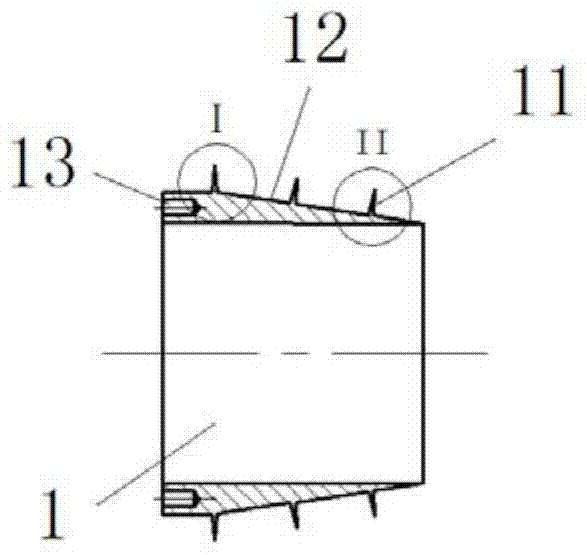

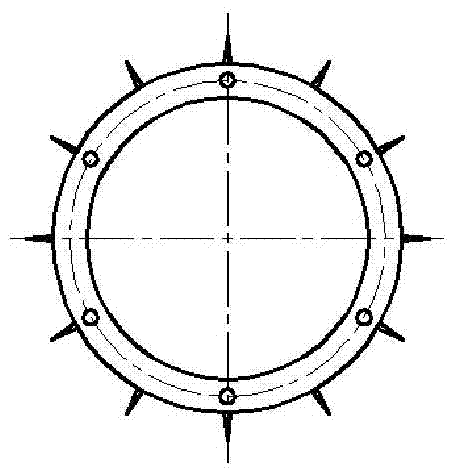

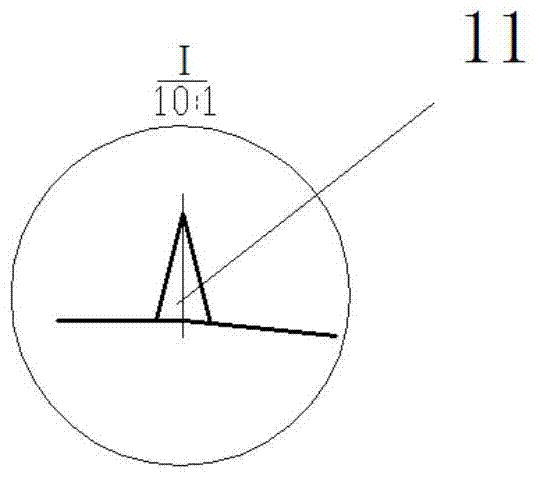

[0037] The technical solution of the present invention is: the carbon fiber composite transmission shaft and the metal flange are not in direct contact, but a tapered Z-pin sleeve transition part is added at the joint, wherein the mandrel transition head enables the Z-pin sleeve to be positioned at The mandrel end is then wrapped with carbon fiber, cured together, cut, de-moulded, and finally the metal flange is pinned to the de-moulded assembly. The method can use the existing fiber winding process and equipment, and the manufacturing cost is low. The invention relates to a Z-pin connection method for a carbon fiber composite transmission shaft and a metal flange, which adds two parts, a Z-pin sleeve and a mandrel transition head, in the process. The Z-pin sleeve is implanted with a needle-shaped metal Z-pin on its tapered surface, which can not only make the carbon fiber transition from the mandrel to the Z-pin sleeve better, but also transmit greater load, and simplify the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com