Grain refining efficient forging method of high-alloy ultrahigh-strength steel large-scale die-forged parts

A technology for ultra-high-strength steel and die forgings, which is applied in the manufacture of large-scale die forgings, and in the field of fine-grained and efficient forging of large-scale die forgings of high-alloy ultra-high-strength steel. Problems such as small deformation, to achieve good promotion and application prospects, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Billet making

[0019] Raw materials: A-100 steel bars with a diameter of Φ300mm, see Table 1 for the chemical composition. The experiment takes 4 forgings as a batch.

[0020] Table 1 A-100 steel bar chemical composition (%wt)

[0021]

[0022] Processing equipment: the heating furnace adopts a box-type resistance furnace, and the forging equipment adopts a 3150-ton fast forging machine;

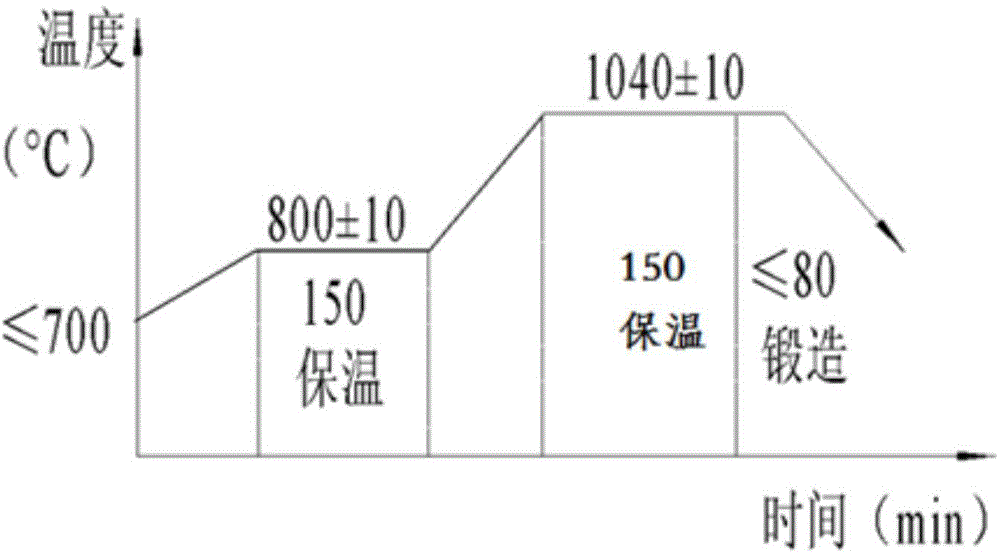

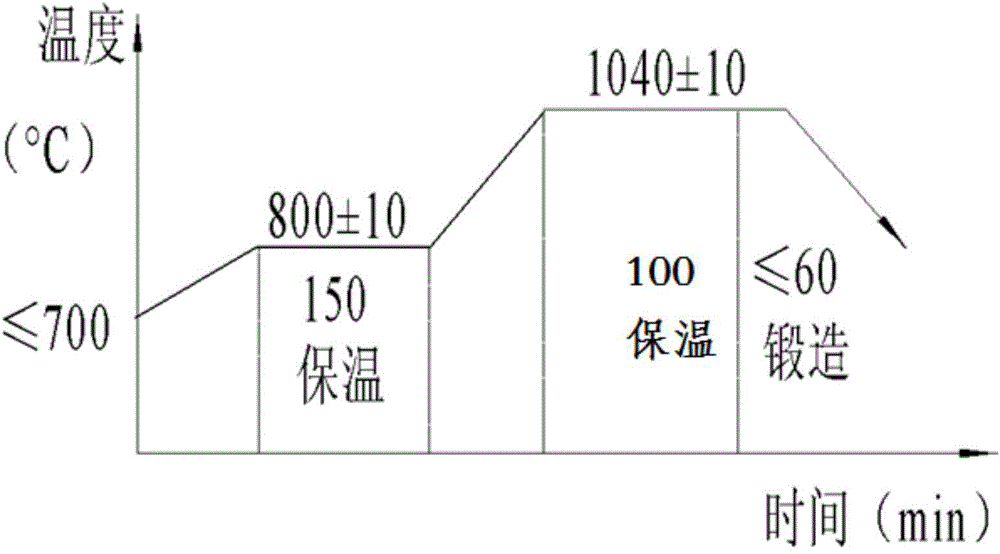

[0023] Heating system: 1045°C, holding time 135min, the specific system is as follows figure 1 As shown, set a temperature sensor on the billet and ensure that the temperature displayed by the sensor does not exceed 1050 °C;

[0024] Deformation system: the deformation amount of each part in a single firing time is more than 30%, but not more than 70%; the deformation speed is controlled at 20-40mm / s; the stop forging temperature: 820℃~850℃;

[0025] Cooling method: air cooling after forging;

[0026] Single billet making time: 14min~18min.

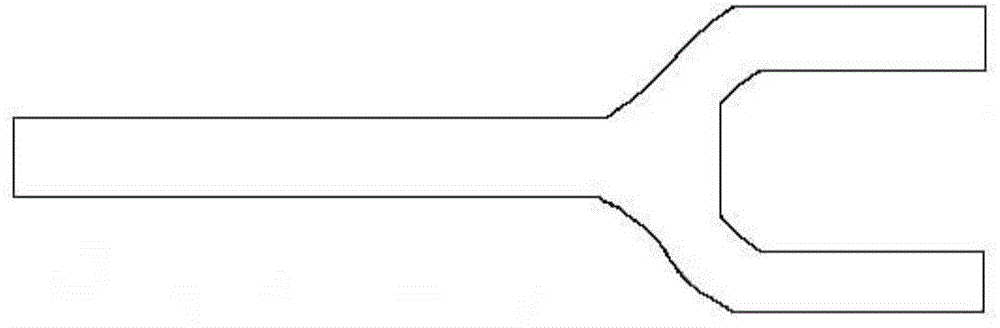

[0027] (2) die forging

[0...

Embodiment 2

[0045] (1) Billet making

[0046] Raw materials: High-alloy ultra-high-strength steel rods with a diameter of Φ200mm, the chemical composition is shown in Table 5. Three forgings were used as a batch in the experiment.

[0047] Table 5 Chemical composition of high-alloy ultra-high-strength steel bars (wt%)

[0048]

[0049] Processing equipment: the heating furnace adopts a box-type resistance furnace, and the forging equipment adopts a 3150-ton fast forging machine;

[0050] Heating system: 1040°C, holding time 110min, the specific system is as follows figure 1 As shown, set a temperature sensor on the billet and ensure that the temperature displayed by the sensor does not exceed 1045°C;

[0051] Deformation system: Deformation amount of each part in a single firing time: more than 30%, but not more than 70%; deformation speed is controlled at 30-50mm / s; stop forging temperature: 820℃~840℃;

[0052] Cooling method: air cooling after forging;

[0053] Single billet mak...

Embodiment 3

[0071] (1) Billet making

[0072] Raw materials: A-100 steel bars with a diameter of Φ300mm, see Table 9 for the chemical composition. The experiment takes 4 forgings as a batch.

[0073] Table 9 A-100 steel bar chemical composition (%wt)

[0074]

[0075] Processing equipment: the heating furnace adopts a box-type resistance furnace, and the forging equipment adopts a 1600-ton fast forging machine;

[0076] Heating system: 1045°C, holding time 135min, the specific system is as follows figure 1 As shown, set a temperature sensor on the billet and ensure that the temperature displayed by the sensor does not exceed 1050 °C;

[0077] Deformation system: Deformation amount of each part in a single firing time: more than 30%, but not more than 70%; deformation speed is controlled at 15-50mm / s; stop forging temperature: 820℃~840℃;

[0078] Cooling method: air cooling after forging;

[0079] Single billet making time: 14min~18min.

[0080] (2) die forging

[0081] Processin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com