Integrated machine for machining of FC-3 aluminum rails

A FC-3, all-in-one machine technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low efficiency, poor position accuracy, etc., and achieve the effect of accurate position and good fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

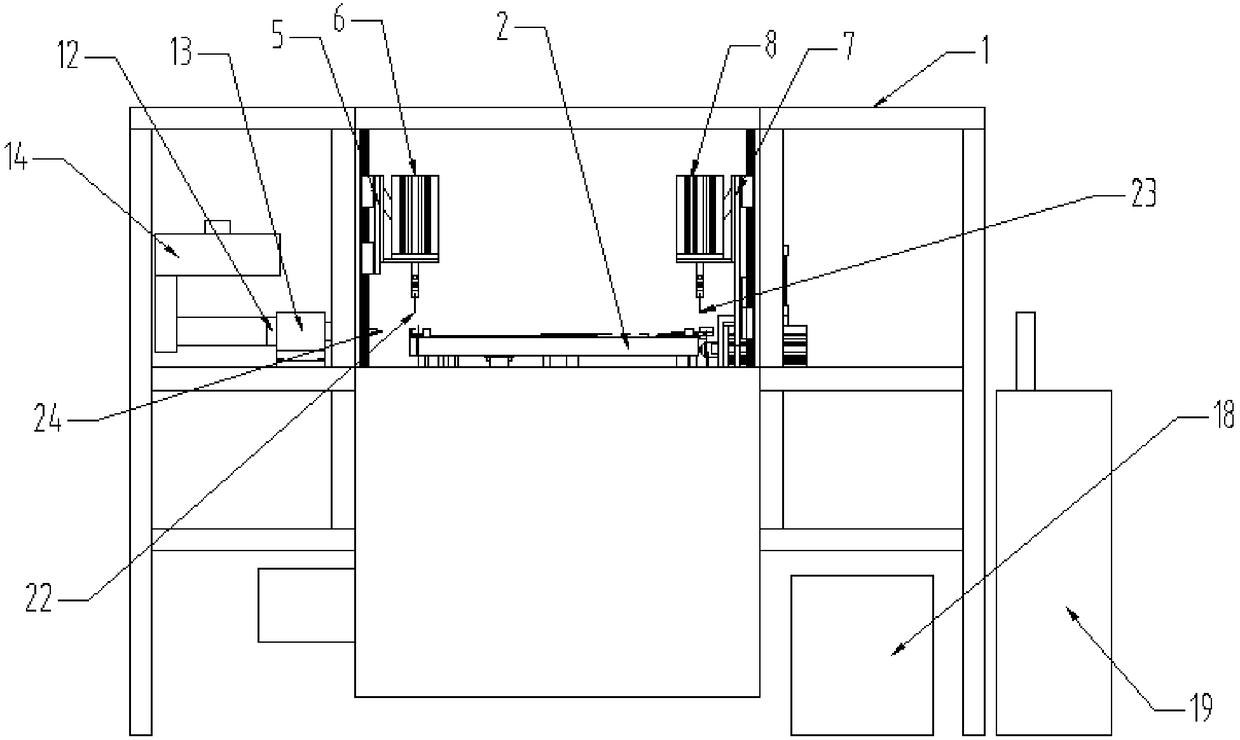

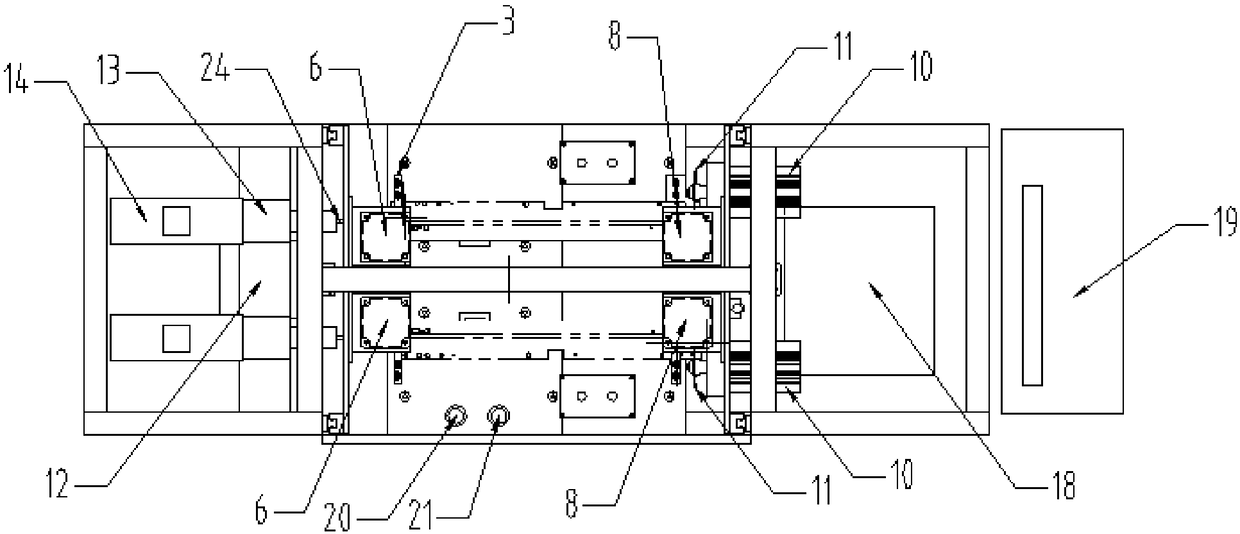

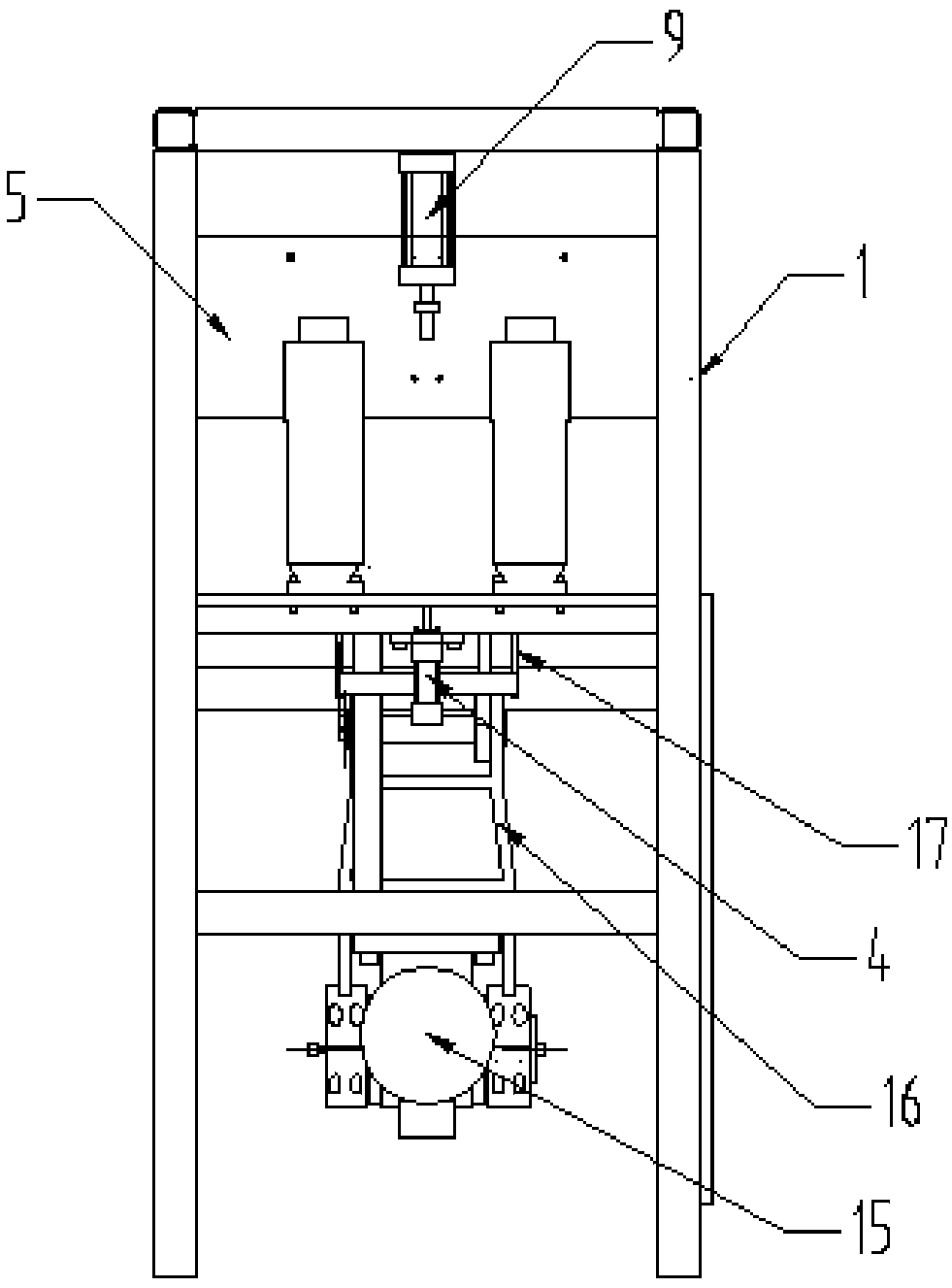

[0024] Such as figure 1 , 2 As shown in and 3, one of the specific embodiments of an FC-3 aluminum rail processing integrated machine includes a stand 1, and two clamps 2 are installed on the front and back of the stand 1. When in use, it will be divided into A pair of aluminum rails of the left aluminum rail and the right aluminum rail are respectively fixed on two fixtures. A clamping device 3 for clamping the left aluminum rail and the right aluminum rail is installed on the two clamps 2. Specifically, the clamps and the clamping device can adopt existing devices to realize a pair of left aluminum rail and the right aluminum rail. The fixing of the right aluminum rail, the structure of the FC-3 aluminum rail is as follows Figure 4 shown. A clamping cylinder 4 is installed on the platform 1, and the clamping cylinder 4 drives the clamping device 3 to clamp two clamps 2. When in use, put the left aluminum rail and the right aluminum rail on the clamps Finally, start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com