Wood strip saw outputting assembly for wood processing machine

A technology for processing machines and wood strips, which is applied in the field of wood blade saw output assemblies for wood processing machines, can solve the problems of reduced production efficiency, low efficiency, and large loss of servo motors, so as to reduce transmission speed, improve transmission efficiency, and ensure The effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

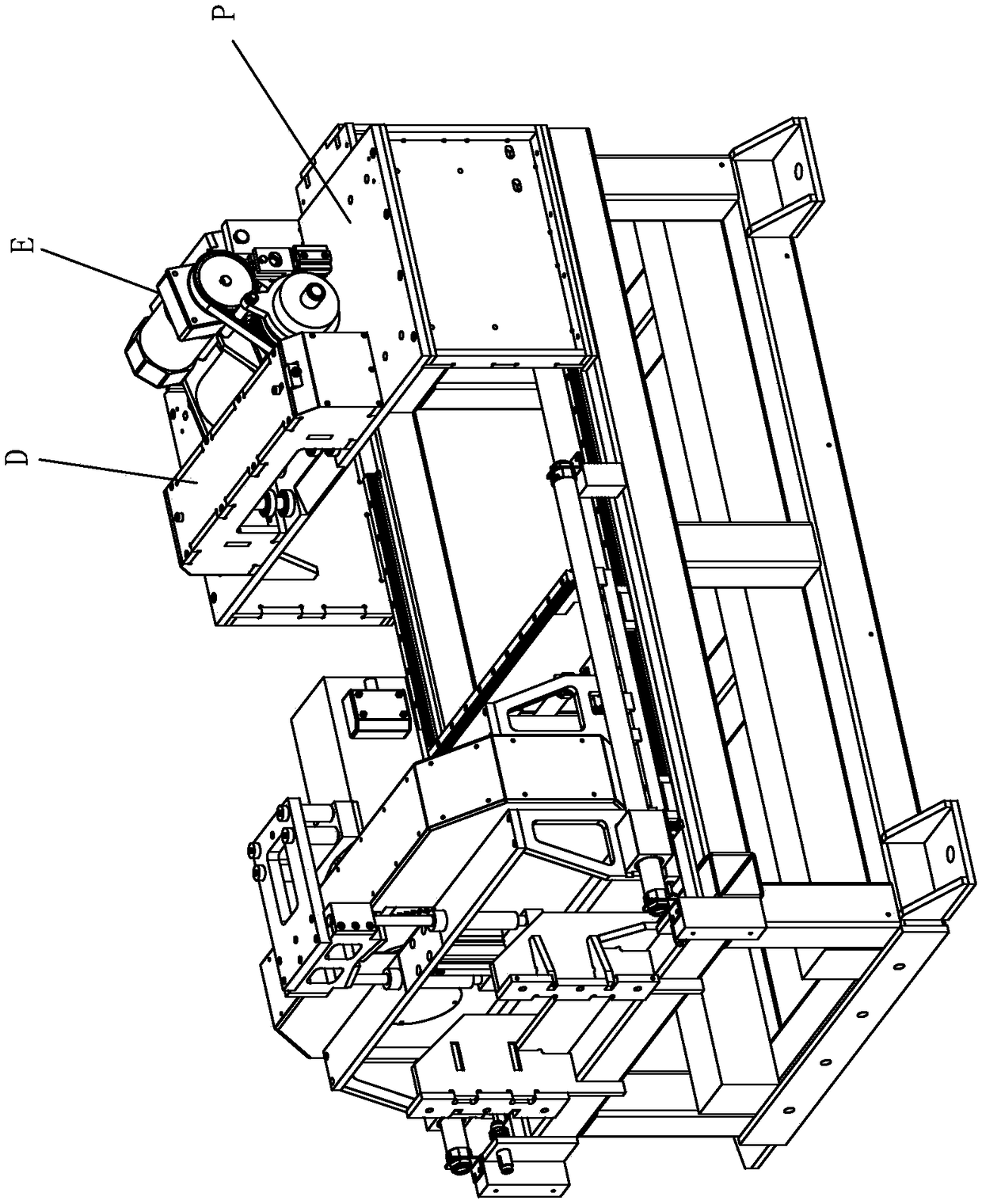

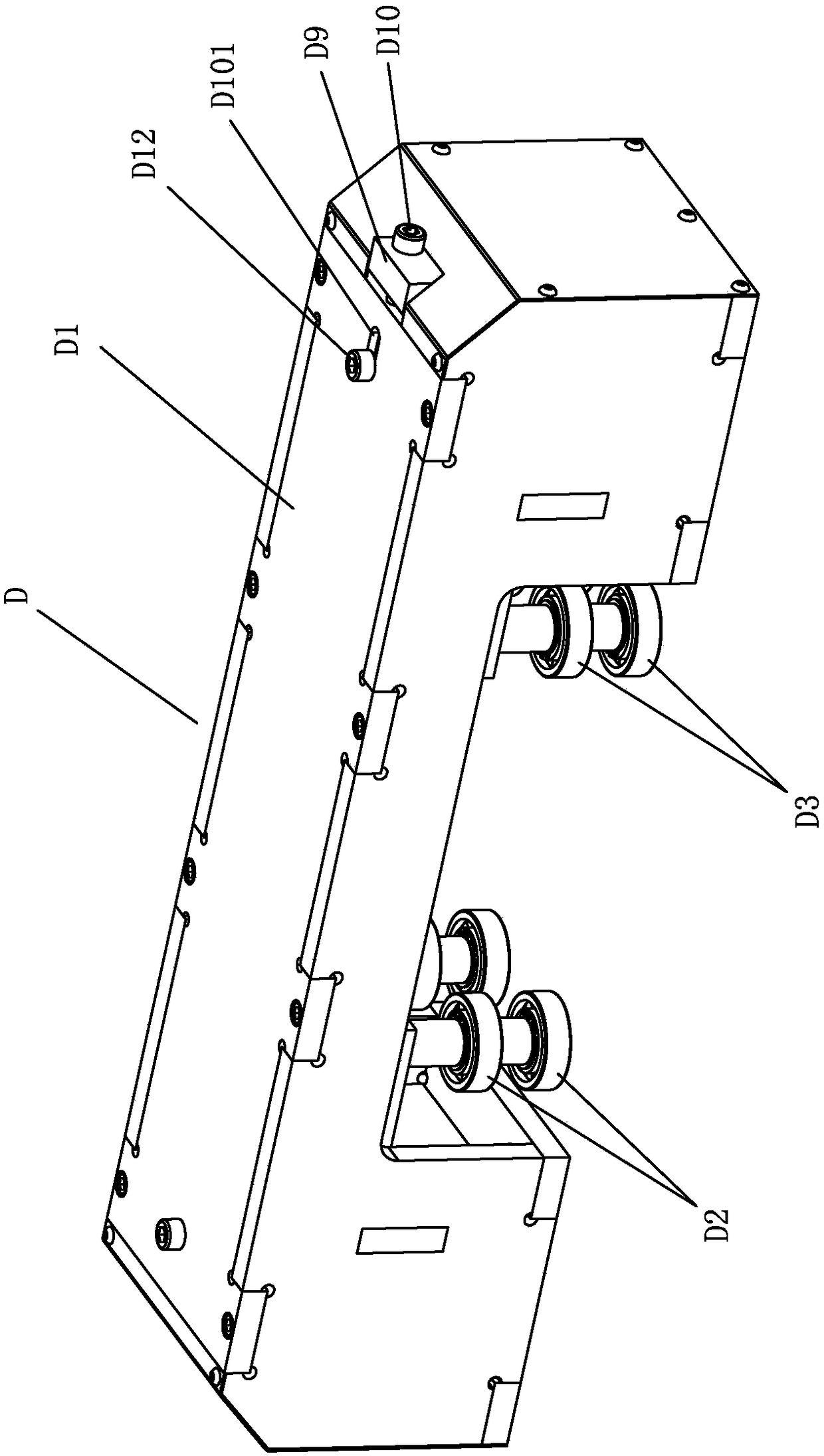

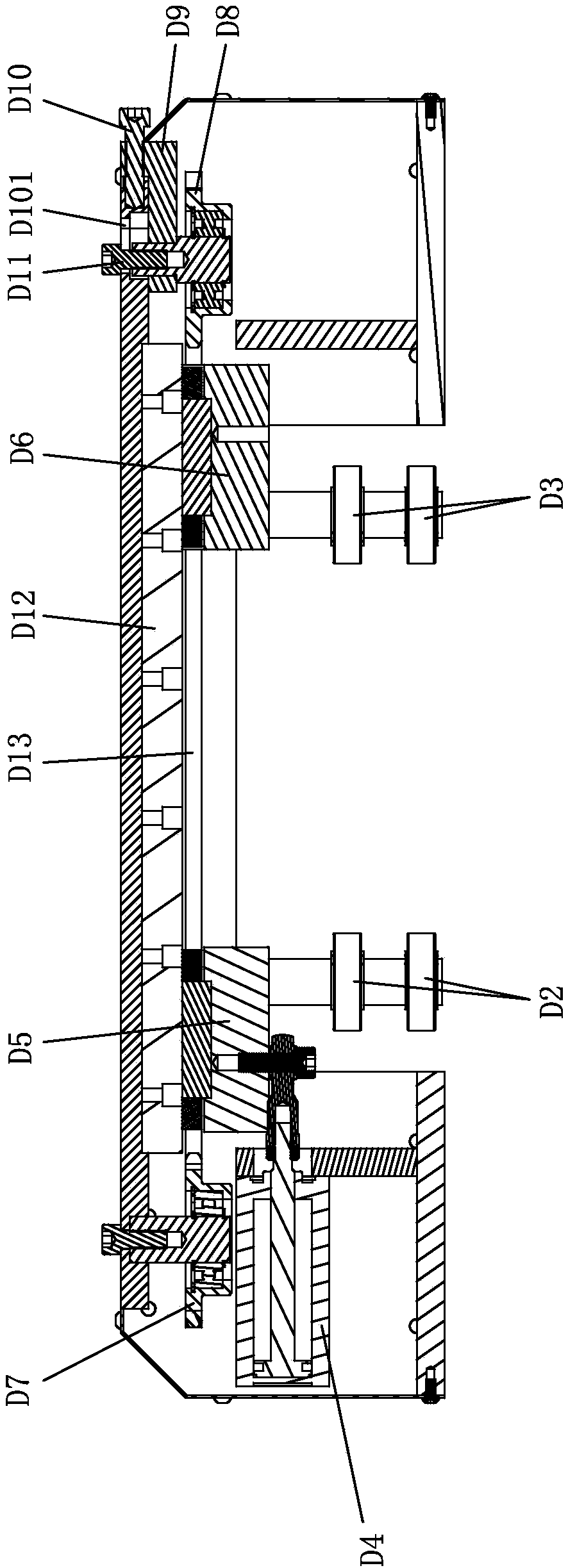

[0030] see Figure 1-Figure 8 , the wood saw output assembly for wood processing machine is applied to the saw and output all-in-one machine for wood strip transmission, connection and sawing, and is used for positioning and outputting the wood strips before and after cutting; The adaptive positioning mechanism D and the damping brake mechanism E on the platform P, the adaptive positioning mechanism D and the damping brake mechanism E are respectively located on the wooden strip transmission line, and the wooden strips pass through the adaptive positioning mechanism D and the damping braking mechanism E in sequence during transmission; The adaptive positioning mechanism D can effectively position the wooden strips to prevent the wooden strips from vibrating or swinging during cutting; the damping brake mechanism E can timely control the transmission spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com