High-frequency current heating and maintaining method for reinforced concrete component production

A reinforced concrete, high-frequency current technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of serious boiler combustion pollution, large maintenance bin area, large steam water consumption, etc., to shorten the concrete solidification cycle, improve Concrete setting speed and the effect of improving concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] For reinforced concrete members that meet the condition of "both ends have steel bar ends that pass through the concrete", based on the above-mentioned inventive concept, the method of this embodiment 1 can be used for concrete maintenance:

[0033] The two output terminals of the high-frequency current generating device are electrically connected to the ends of the steel bars at both ends of the reinforced concrete member, so that the high-frequency current output by the high-frequency current generating device flows through the steel bars in the reinforced concrete member, so that the steel bars in the reinforced concrete member Heat is generated on the steel bars, causing the heat to act on the concrete of the reinforced concrete member.

[0034] Therefore, by loading the high-frequency current on the steel bar of the reinforced concrete member, the high-frequency current is used to generate heat through the distributed resistance of the steel bar, and the converted h...

Embodiment 2

[0036] For all types of reinforced concrete members, including reinforced concrete members that meet the condition of "both ends have steel bar ends that penetrate the concrete" and reinforced concrete members that do not meet this condition, based on the above-mentioned inventive concept, this implementation method can be adopted. Carry out concrete curing in the way of Example 2:

[0037] The high-frequency current generated by the high-frequency current generator is converted into heat through the heating coil, that is, the two output terminals of the high-frequency current generator are electrically connected to the two ends of the heating coil, and the heating coil is installed inside a tubular curing body The tubular curing body can be a square tube or a round tube. The outer wall of the tubular curing body is covered with an insulating layer. A circulating fan is also installed inside, and when the two insulation doors of the tubular curing body are closed, the circulat...

Embodiment approach

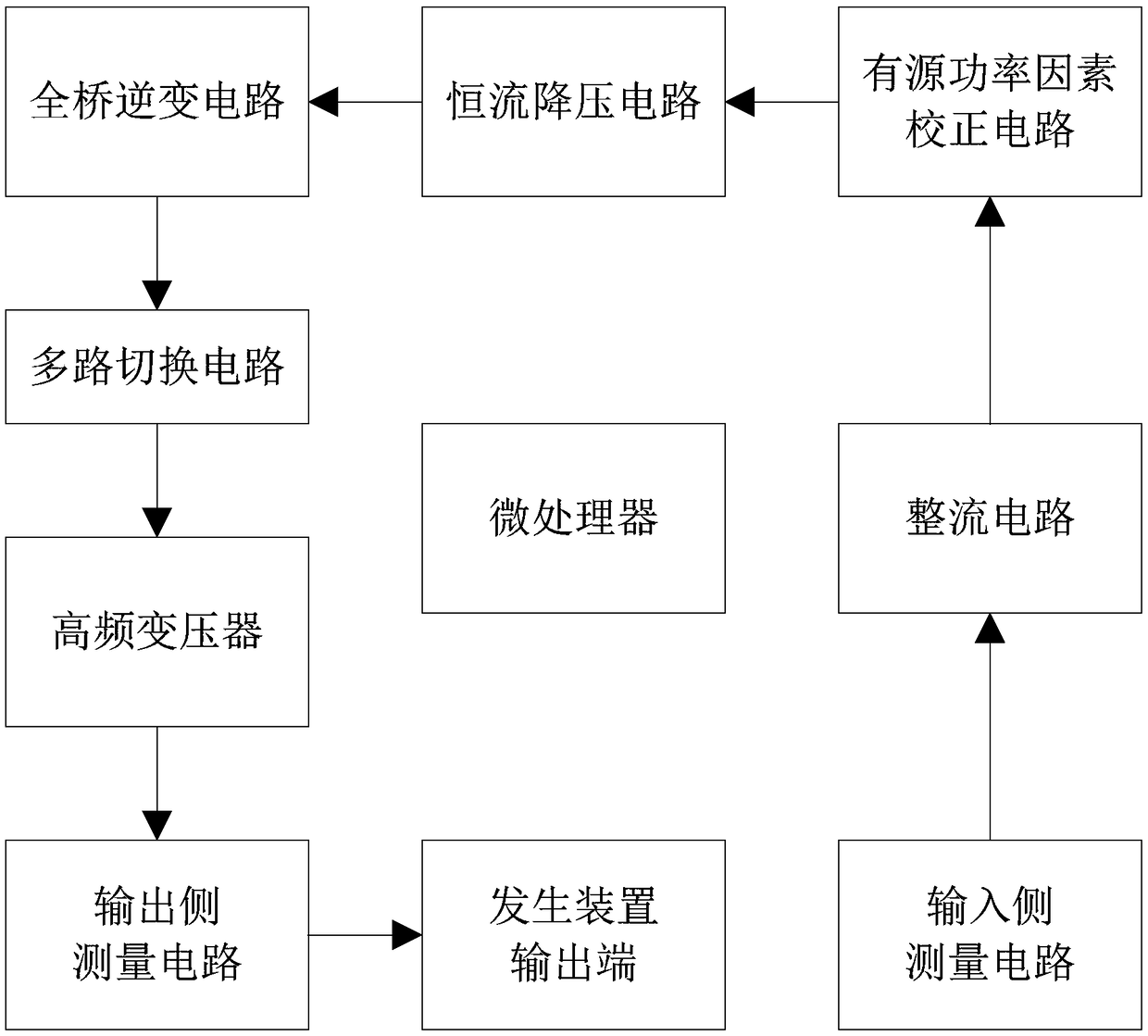

[0041] As a preferred embodiment of the present invention: as figure 1 As shown, the high-frequency current generator is equipped with a rectifier circuit, a full-bridge inverter circuit, a multi-channel switching circuit, a high-frequency transformer, a microprocessor, and an output terminal of the generator; the rectifier circuit converts the AC input from the external power supply into DC, and the The direct current is input into the full-bridge inverter circuit, and the full-bridge inverter circuit converts the input direct current into high-frequency alternating current, and the microprocessor can control the frequency of the high-frequency alternating current output by the full-bridge inverter circuit, wherein the microprocessor preferably passes PWM The signal controls the frequency of the high-frequency alternating current output by the full-bridge inverter circuit, and the multi-way switching circuit has one input terminal and multiple output terminals, and the high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com