Metallurgy mine vehicle wheel

A mining wheel and hub technology, applied in the direction of wheels, spoke wheels, rims, etc., can solve the problems of unreasonable structure, low mold preheating temperature, increased crack tendency, etc., and achieve beautiful appearance design and low production cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

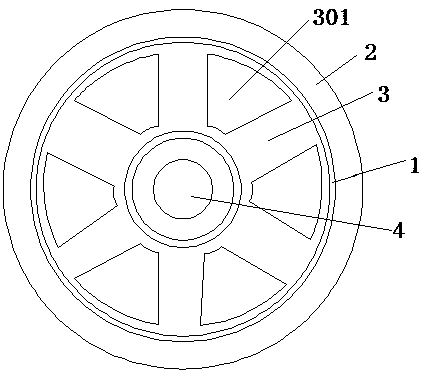

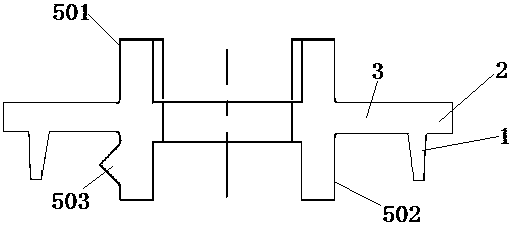

[0017] Example: such as Figure 1-2 As shown, the metallurgical mine wheel includes a tread 1 and a hub 3, the tread 1 and the hub 3 are integrally formed, the tread 1 is vertically connected to the hub 3; the tread 1 is connected to the hub 3 The hub 3 is provided with a rim 2 extending outward along the horizontal direction with the hub 3; the hub 3 is in a concave shape, and the center of the hub 3 is provided with a shaft hole 4; the hub 3 is provided with several through holes 301; the connection between the shaft hole 4 and the hub 3 is extended to both ends along the radial direction of the shaft hole 4, and an upper shaft surface and a lower shaft surface are respectively provided; the tread surface 1 is trapezoidal, and the bottom edge of the trapezoid is in line with the The rims 2 are connected, and the outer circumference of the rim 2 is arc-shaped; the upper axial surface is located at the end away from the tread 1, and the lower axial surface is parallel to the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com