Lead acid accumulator transportation walking vehicle

A technology of lead-acid batteries and walking vehicles, which is applied in the directions of transportation and packaging, conveyors, storage devices, etc., and can solve the problems of large floor space, inconvenient height adjustment, inconvenient climbing up and down, etc., to achieve Good energy saving effect, improve production efficiency and economic benefits, use flexible and variable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

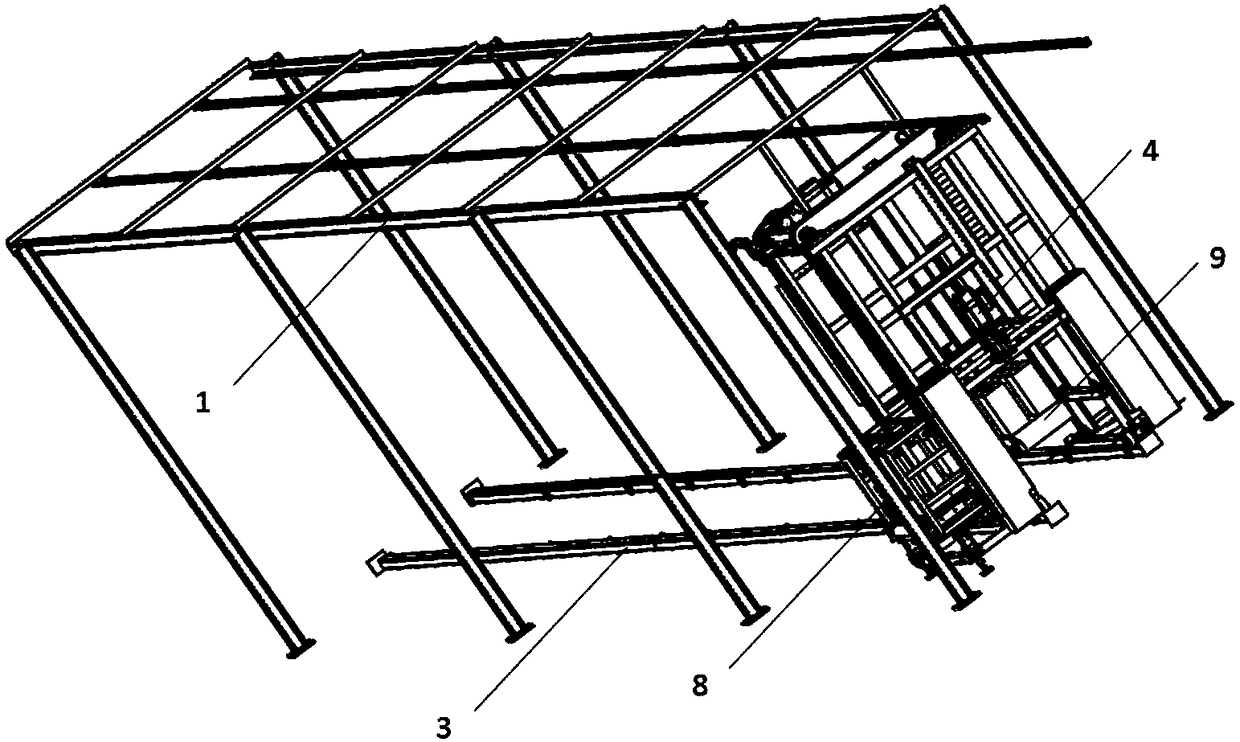

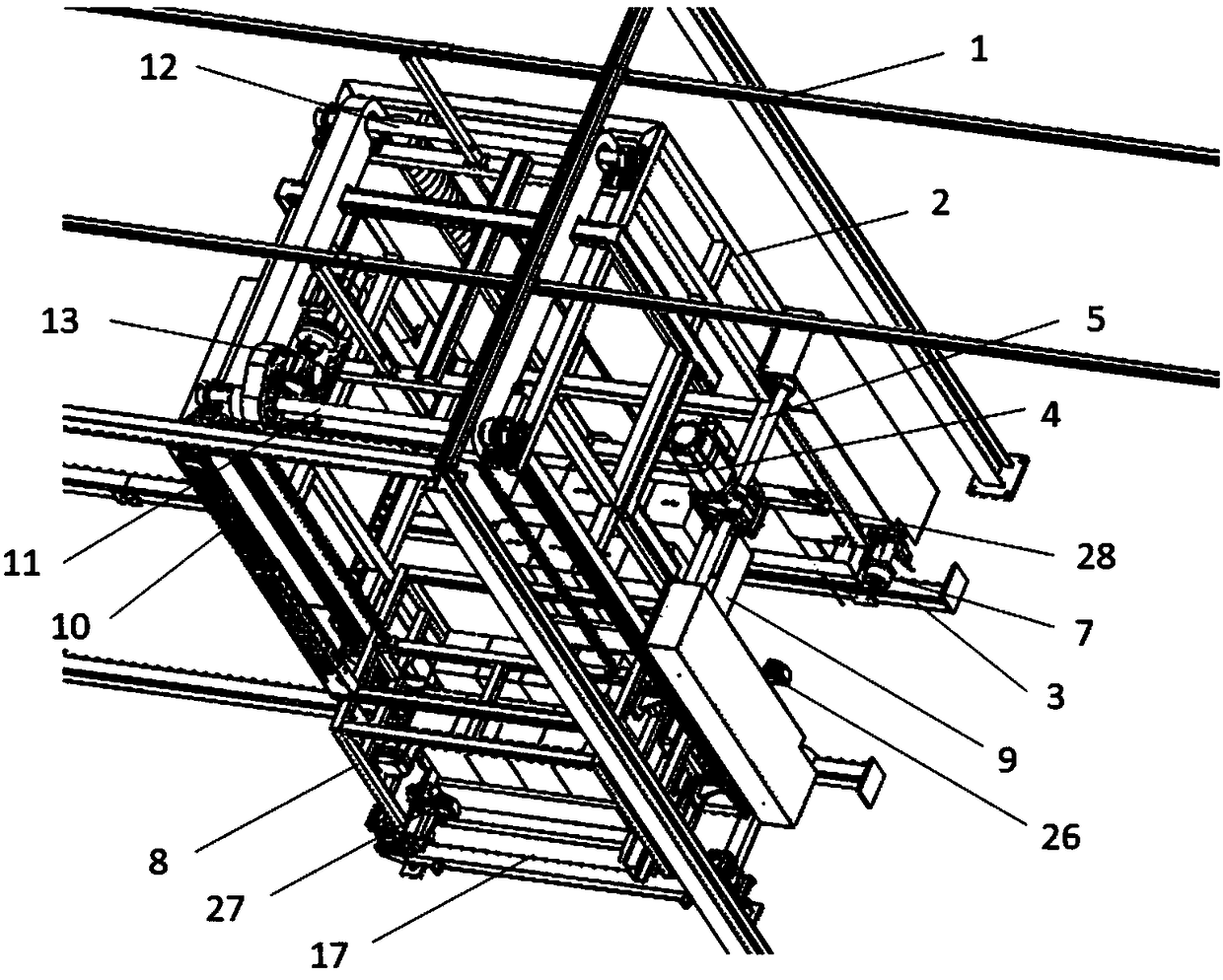

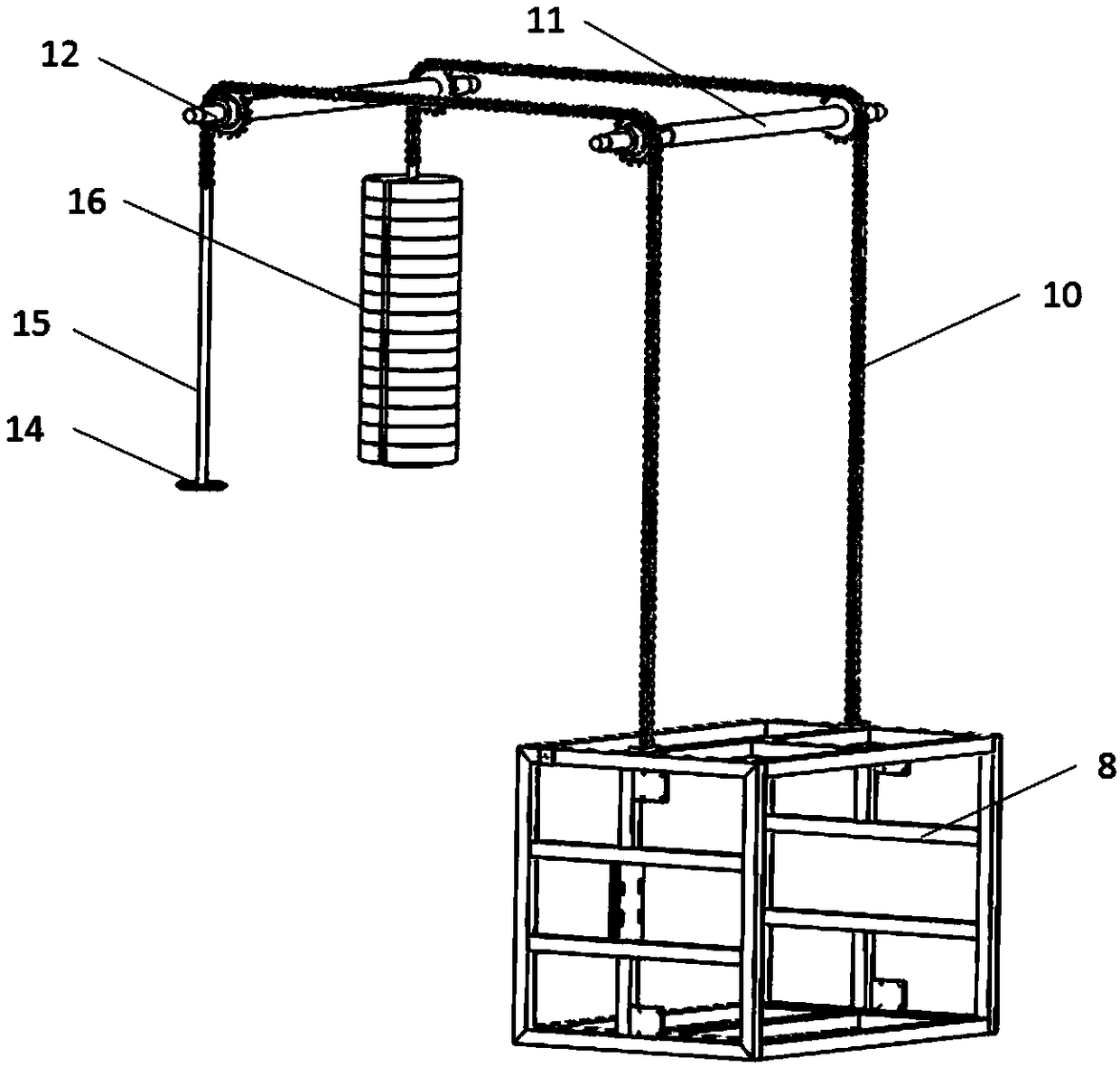

[0025] A lead-acid battery transporting trolley, comprising a bracket 1, a traveling frame 2, the traveling frame 2 moves along the guide rail 3 at the bottom of the support 1, and a roller conveyor belt is arranged between the guide rails 3 for transporting the battery tray 9, the trolley It also includes a traveling device, a lifting device, a jacking device, a counterweight device, a first reading and writing device, and a second reading and writing device; At the end of the walking frame 2, perpendicular to the guide rail 3, the traveling motor 4 is arranged on the horizontal axis 5, and the two ends of the horizontal axis 5 are respectively connected with the vertical axis 6 through gears, and the other ends of the vertical axis 6 are connected with the walking frame 2 respectively. The walking wheels 7 below are connected by gears; the lifting device includes a lifting frame 8 arranged on the side of the guide rail 3 and a lifting drive mechanism that controls the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com