Auxiliary framework for fork of fork truck used for loading operation of containers

A technology of auxiliary frame and container, applied in the direction of lifting device, etc., can solve the problems such as the inability to meet the packing requirements and the inconvenient length of the fork of the forklift, and achieve the effects of saving transportation costs, increasing the effective working distance, and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

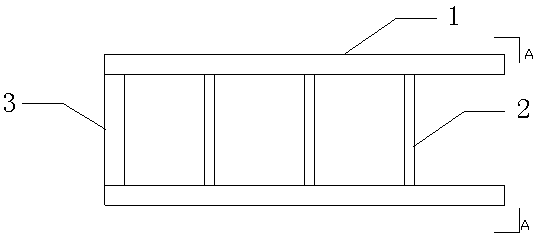

[0026] The forklift fork auxiliary frame for container packing operation of the present invention, one end of the auxiliary frame is used to connect with the packaging pallet, and the other end is connected with the fork of the forklift, including two first square steel pipes 1 and three second square steel pipes 2 And a 3rd party steel pipe 3.

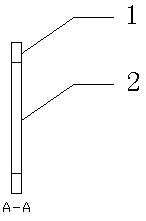

[0027] see now figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the forklift auxiliary frame of the forklift according to the embodiment of the present invention, figure 2 for figure 1 Sectional view of A-A in Fig. As shown in the figure, the lengths of the two first square steel pipes 1 are equal, arranged parallel to each other, and the distance between them is 1100mm; Q345B.

[0028] The length of the third square steel pipe 3 is 1100mm, and it is welded and fixed between the ends of the two first square steel pipes 1. The second pallet fork of the forklift is inserted into two first-party steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com