Lifting and rotating device and 3D house printer

A technology of lifting, rotating, and rotating components, which is applied in construction, building construction, and building material processing. It can solve the problems of limited printing range and cumbersome operation, and achieve the effects of improving utilization, simplifying steps, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

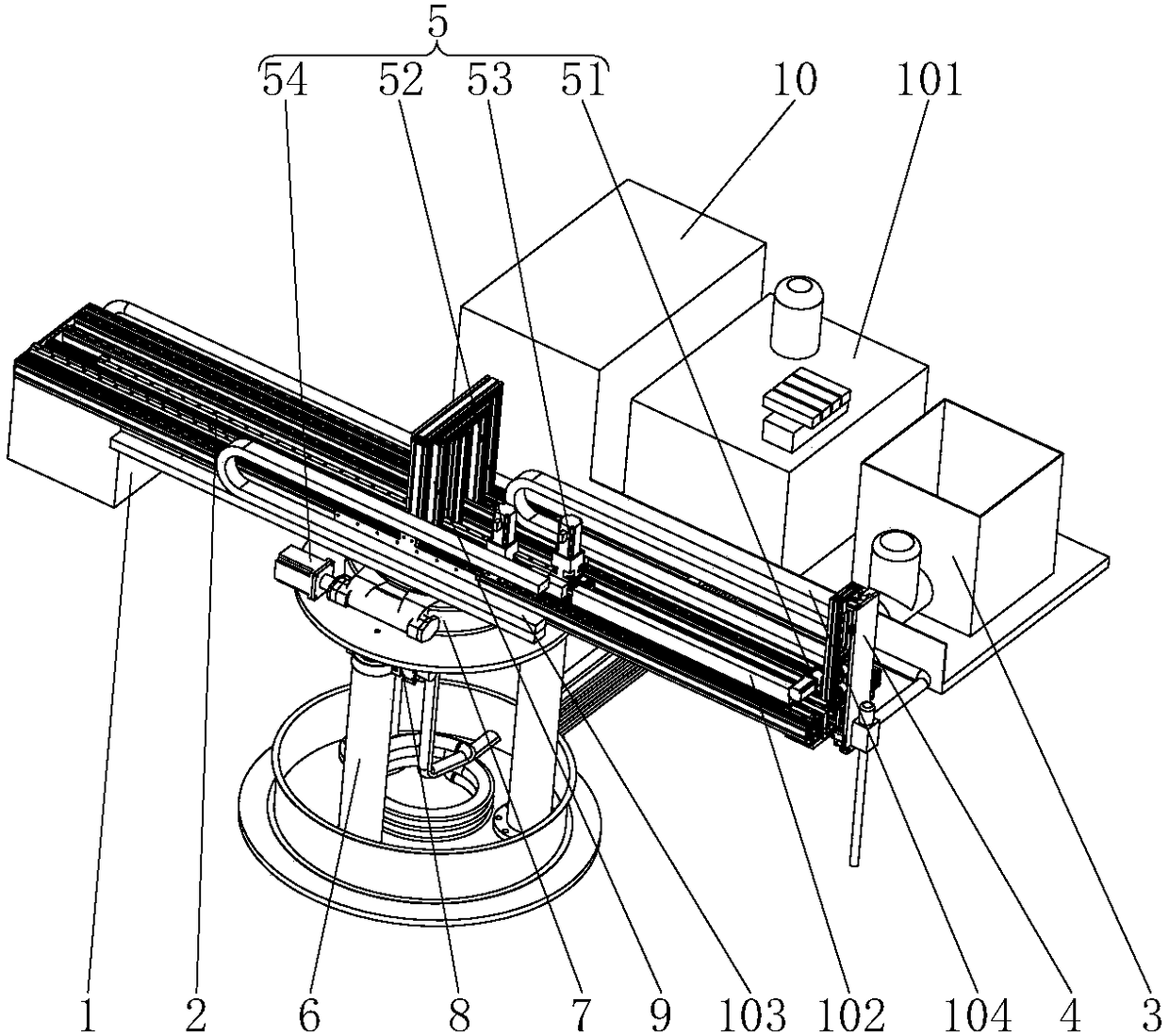

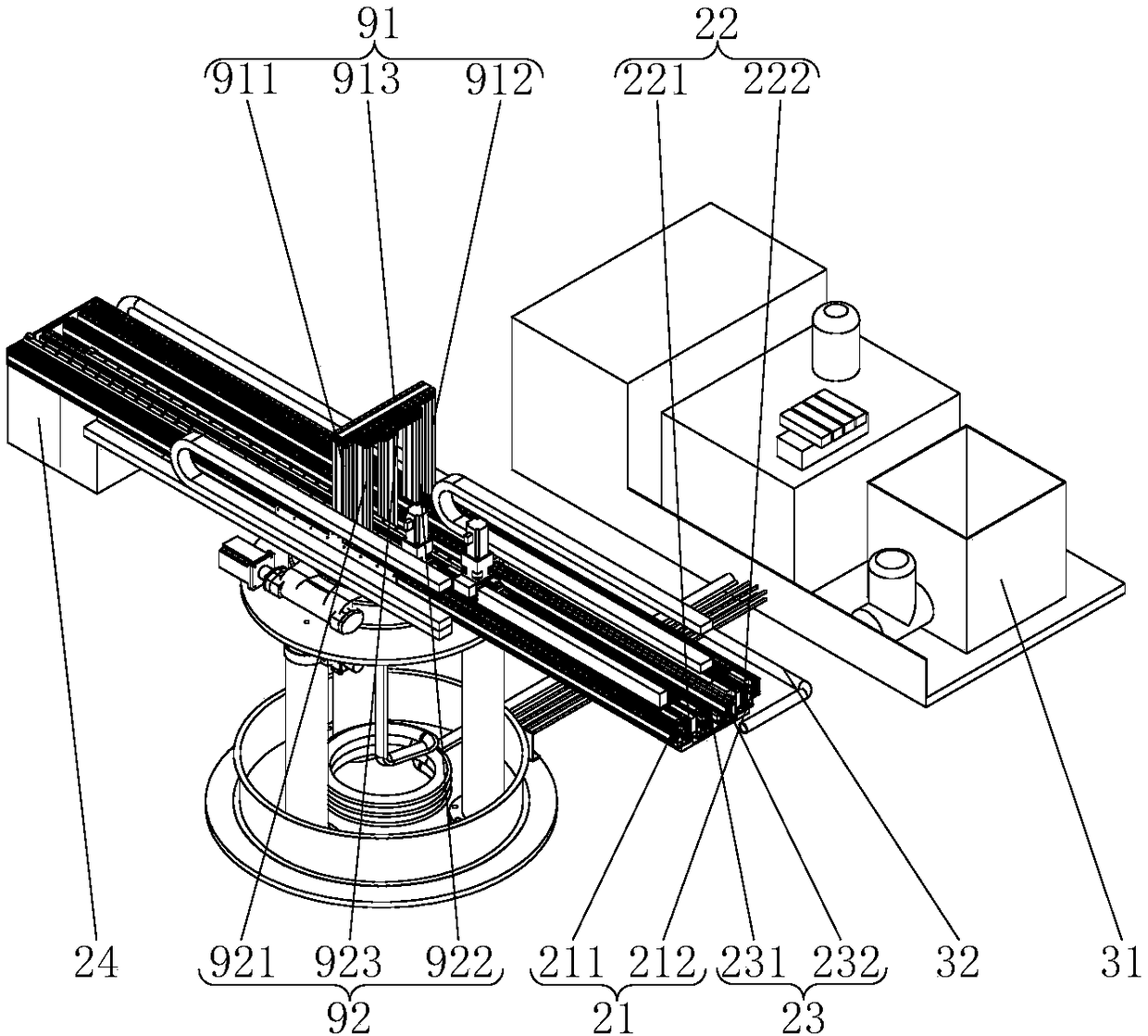

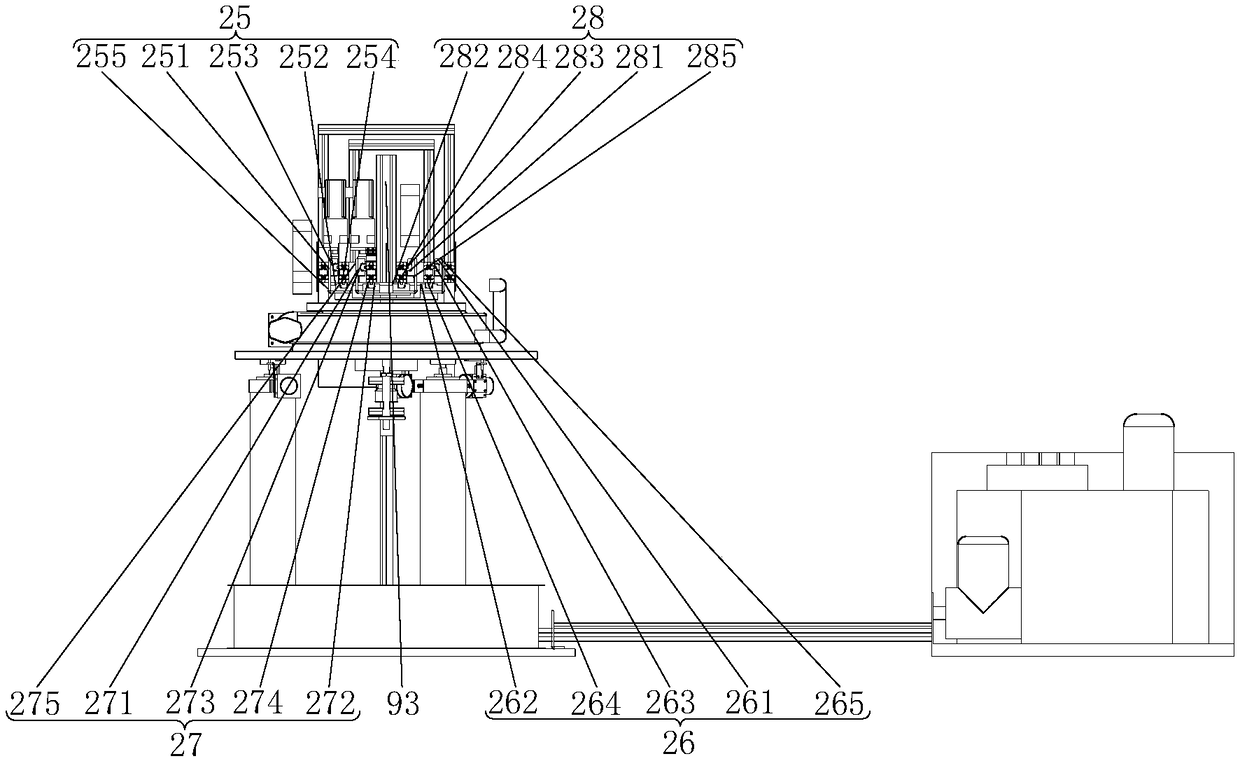

[0062] Such as Figure 1 to Figure 10 As shown, it includes a first driving member 54, a rotating assembly 7, a lifting assembly 6 and a walking assembly;

[0063] The first driving member 54 is connected with the rotating assembly 7;

[0064] The truss assembly 2 is arranged on the rotating assembly 7, and the rotating assembly 7 is used to drive the truss assembly 2 to rotate;

[0065] The lifting assembly 6 is arranged below the rotating assembly 7 for supporting the rotating assembly 7 and driving the rotating assembly 7 up and down;

[0066] The walking assembly is arranged below the lifting assembly 6 for driving the lifting assembly 6 and the rotating assembly 7 to move.

[0067] The lifting and rotating device includes a first driving member 54, a rotating assembly 7, a lifting assembly 6 and a walking assembly, the first driving member 54 is connected with the rotating assembly 7, and the rotating assembly 7 is provided with a truss assembly 2, and the rotating asse...

Embodiment 2

[0089] Such as Figure 1 to Figure 10 As shown, a 3D house printer provided in this embodiment includes the lifting and rotating device provided in Embodiment 1, and also includes a control assembly 1 and a truss assembly 2 connected to the control assembly 1, a feeding assembly 3, and a discharging assembly 4 and drive assembly 5;

[0090] The feeding assembly 3 is connected with the discharging assembly 4 for conveying building materials to the discharging assembly 4;

[0091] The discharge assembly 4 is arranged at one end of the truss assembly 2 for unloading when printing a house;

[0092] The driving assembly 5 is respectively connected with the truss assembly 2, the discharging assembly 4, the lifting assembly 6 and the rotating assembly 7, and is used to respectively drive the movement of the truss assembly 2, the discharging assembly 4, the lifting assembly 6 and the rotating assembly 7;

[0093] The lifting assembly 6 is arranged below the truss assembly 2 for adjust...

Embodiment 3

[0205] Different from Embodiment 2, the lifting component 6 adopts a tower crane.

[0206] Further, the number of tower cranes may be one, which is set at the center of the base 64 and connected with the center of the rotating assembly 7 .

[0207] Further, there may be multiple tower cranes, which are evenly spaced at the center of the base 64 and connected with the rotating assembly 7 .

[0208] In this city, using a tower crane as the lifting component 6 of the device can complete the construction of houses with higher height requirements.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap