V-shaped seam forming device and technology thereof

A molding process and molding device technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of unfavorable construction cost, time-consuming and labor-consuming, etc., and achieve the effect of shortening operation time and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

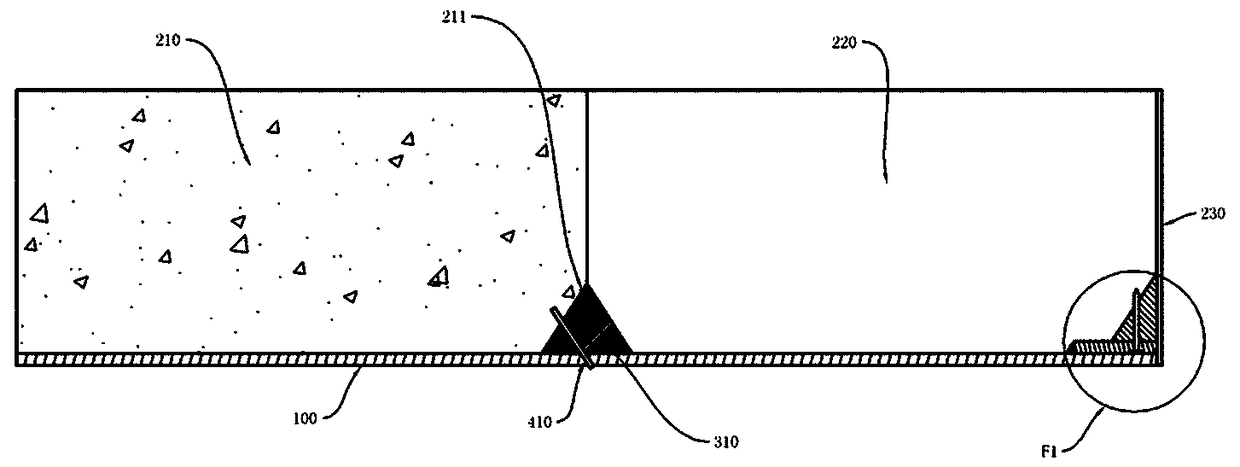

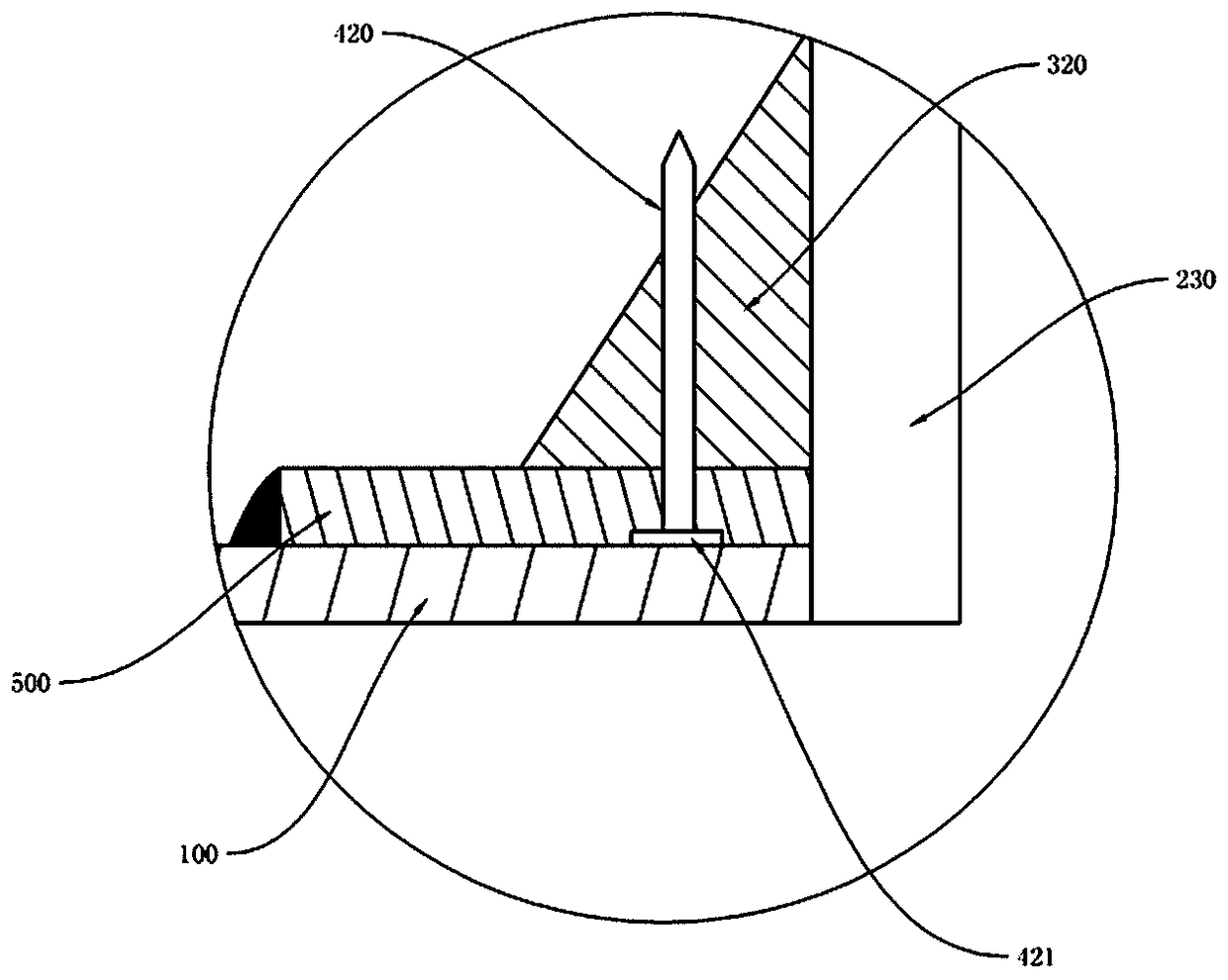

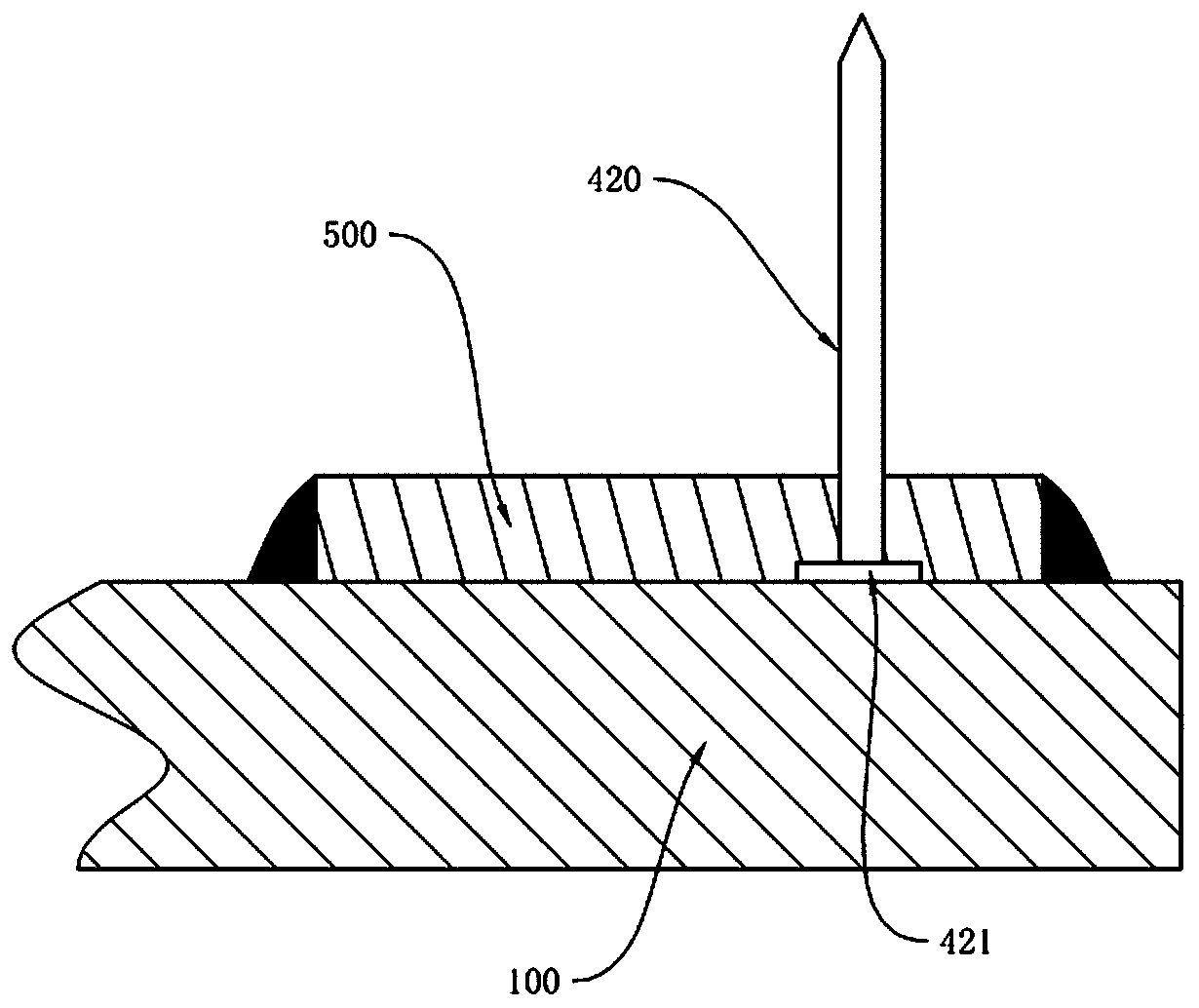

[0024] see Figure 1-Figure 3 , a V-shaped seam forming device, including a first rubber strip 310 and a second rubber strip 320, the end faces of the first rubber strip 310 and the second rubber strip 320 are triangular, preferably, the first The end surface of the rubber strip 310 is an isosceles triangle, and the end surface of the second rubber strip 320 is a right triangle;

[0025] After the tip of the second rivet 420 passes through the steel plate 500, the second rubber strip 320 is fixed on the steel plate 500. The large end 421 of the second rivet 420 is closely fixed to the panel 100 of the initial construction trolley, and the steel plate 500 and the initial construction The trolley panel 100 is welded and fixed.

[0026] A V-shaped seam forming process based on the above-mentioned V-shaped seam forming device, comprising the steps of:

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com