Exhaust pipe

A technology for exhaust pipes and sliding sleeves, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc., which can solve the problems of easy adhesion of impurities in exhaust pipes, and achieve the effects of avoiding excessive moisture and enhancing the scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

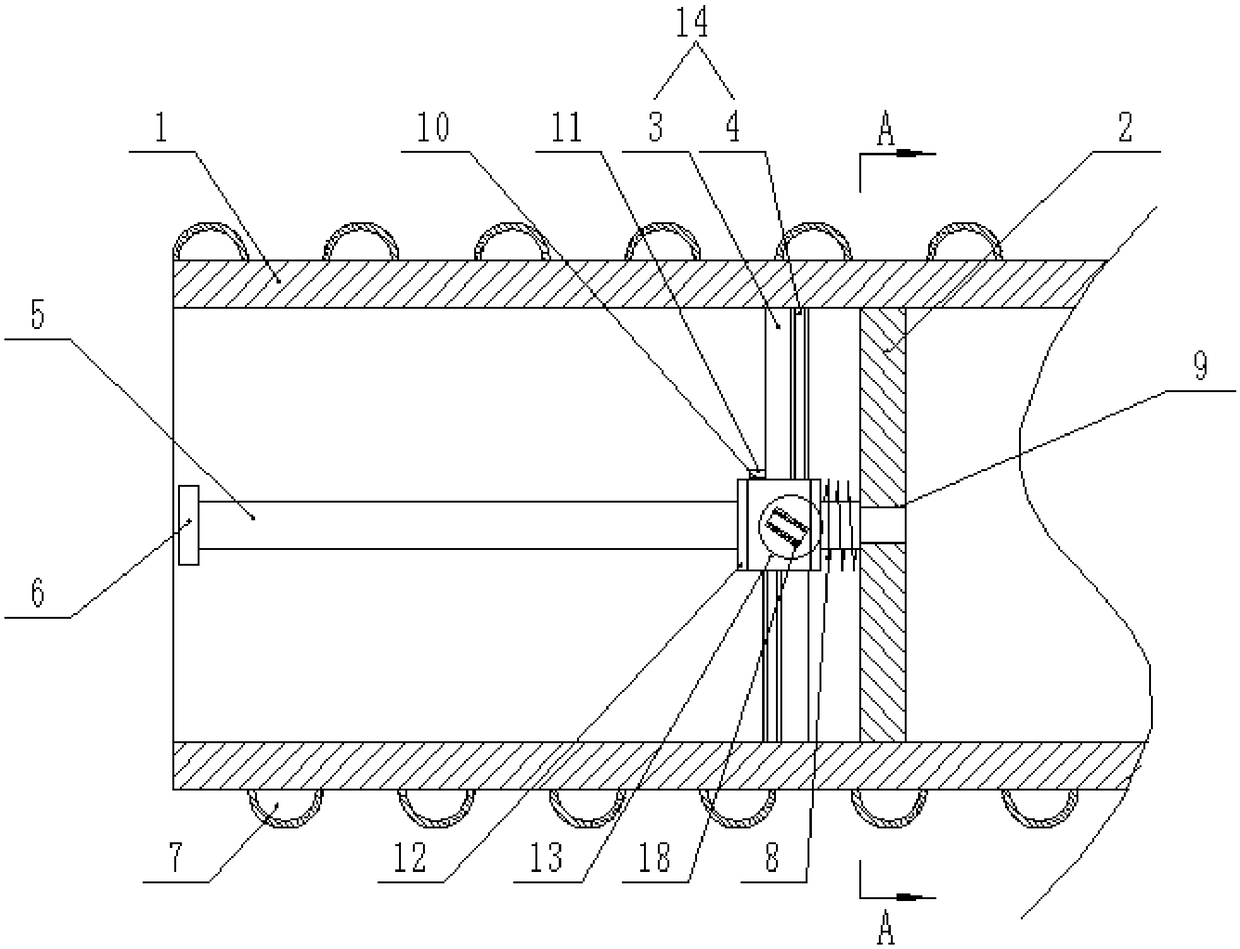

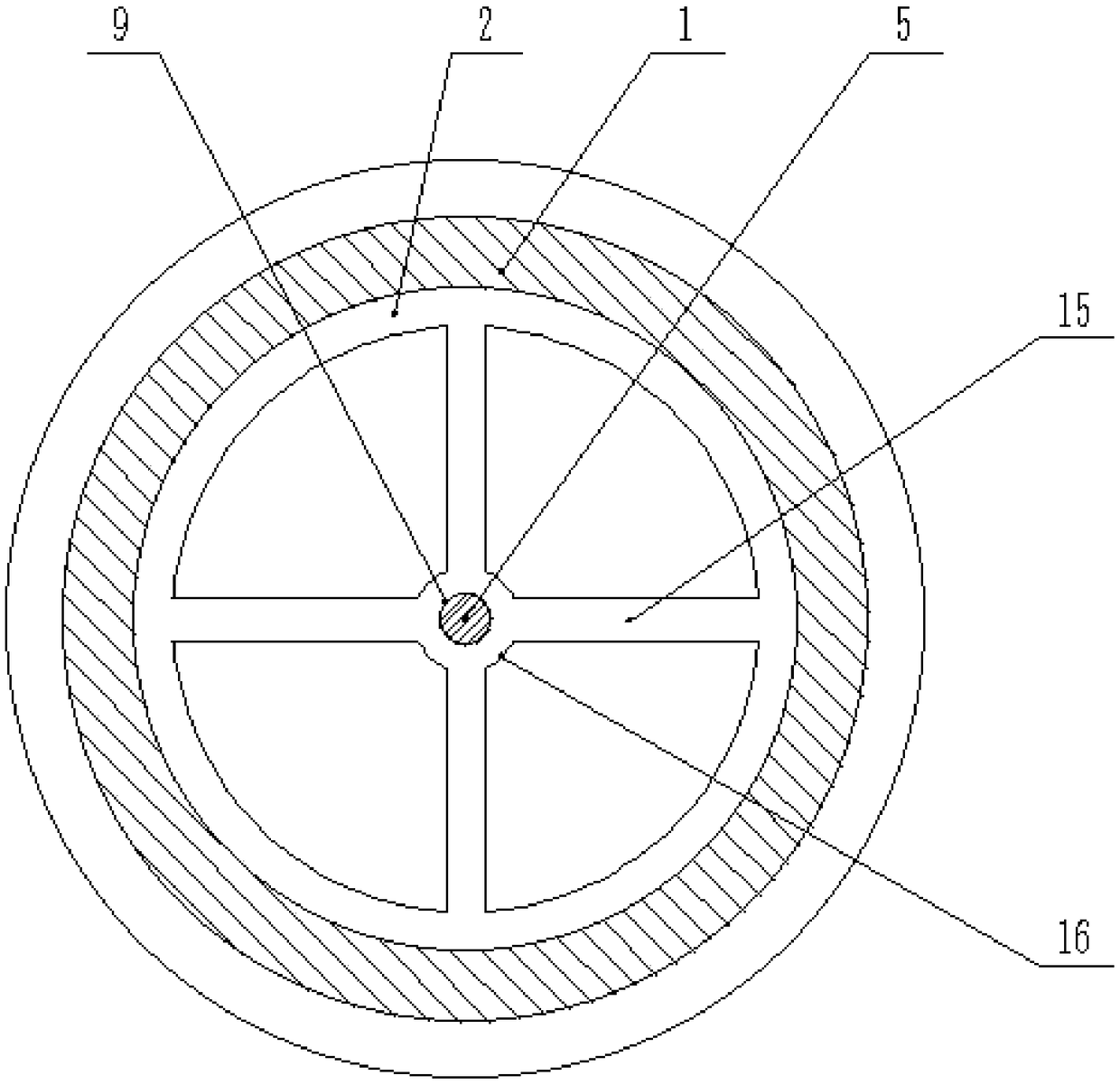

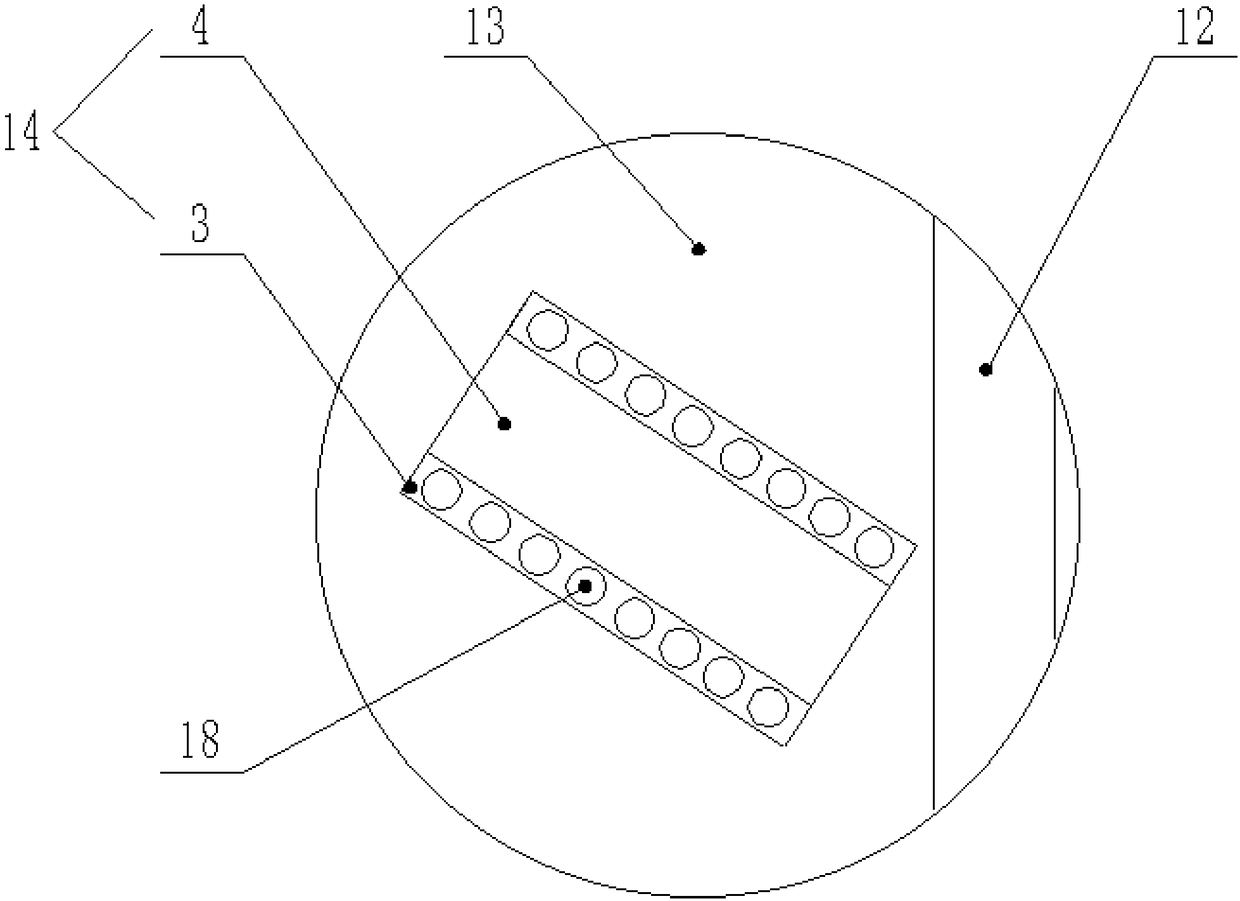

[0018] The reference signs in the drawings of the specification include: exhaust pipe 1, positioning bracket 2, splint 3, sponge layer 4, guide rod 5, limit boss 6, cooling pipe 7, tension spring 8, internal threaded hole 9, inlet Liquid port 10, sealing door 11, sliding sleeve 12, rotating sleeve 13, blade 14, positioning rod 15, positioning piece 16, liquid storage cavity 17, liquid outlet hole 18.

[0019] The embodiment is basically as figure 1 , figure 2 , image 3 and Figure 4 Shown: an exhaust pipe 1, including an exhaust pipe 1, an annular positioning bracket 2 is coaxially integrally formed in the exhaust pipe 1, and a positioning rod 15 in the shape of a "ten" is integrally formed on the inner wall of the positioning bracket 2 The intersection point of the positioning rod 15 is integrally formed with a circular positioning piece 16, the center of the positioning piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com