Micro valve capable of controlling liquid flowing and micro flow control chip

A microfluidic chip and liquid flow technology, applied in the direction of fluid controllers, valve devices, engine components, etc., can solve the problems of difficult and precise control of fluid flow, pollution, built-in detection reagents, etc., to simplify steps and external hardware equipment, avoid mutual pollution, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In the following detailed description, reference texts accompanying the legends are a part hereof and are presented by way of illustration of certain embodiments in which the invention may be practiced. We do not exclude that the present invention can implement other specific solutions and change the structure of the present invention without departing from the scope of use of the present invention.

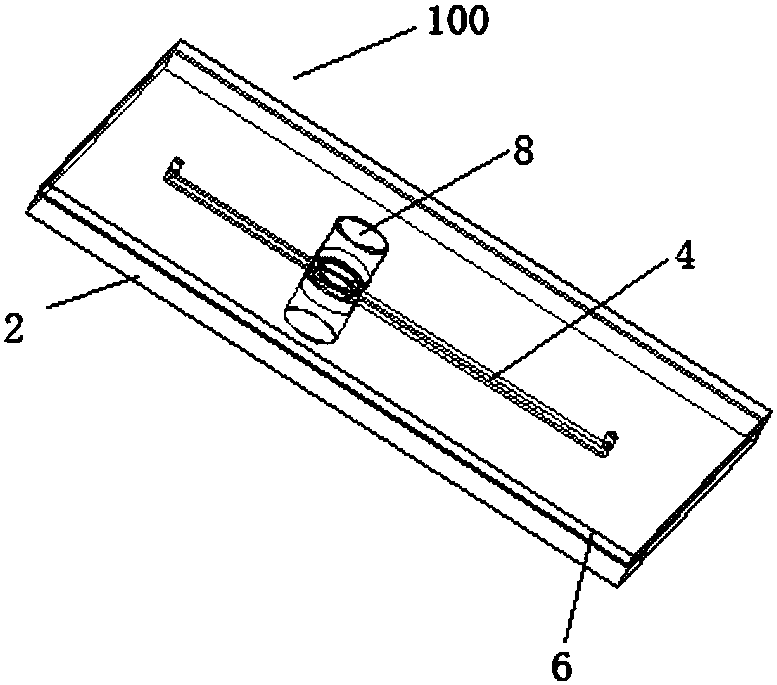

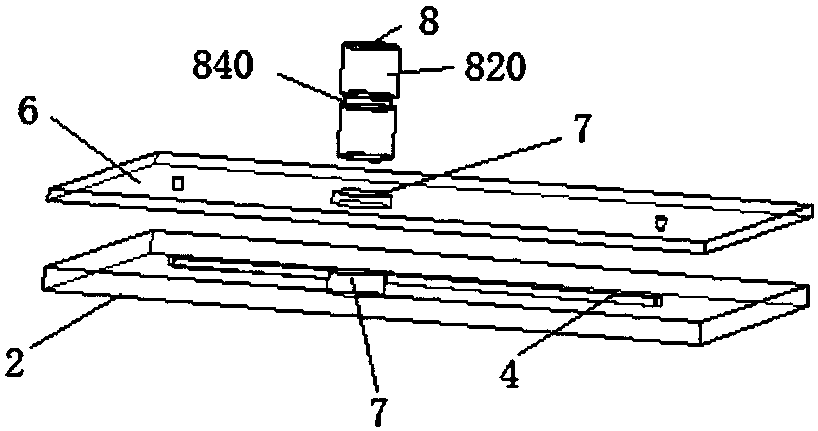

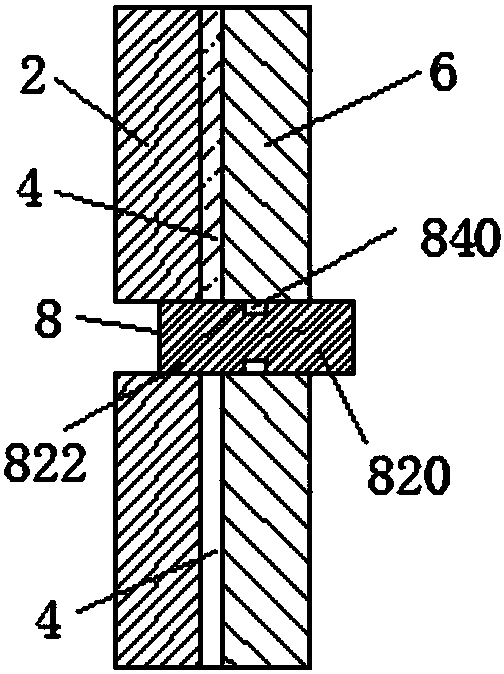

[0080] Such as figure 1 , figure 2 , image 3 with 4 The shown microfluidic chip 100 includes a substrate 2, a microchannel 4 arranged on the substrate, a cover sheet 6 covering the substrate, and a microvalve for controlling the on-off of the microchannel 4 is provided on the channel of the microchannel 4. 8. There is a microvalve socket 7 for installing a microvalve on the chip. The microvalve 8 includes a valve body 820 and a guide channel 840 arranged on the piston. in such as Figures 3 to 4 In the illustrated embodiment, the microvalve is a push-type microvalv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com