Controller system for sensing clamping of machine clamp and control method thereof

A controller and micro-controller technology, applied in general control systems, control/regulation systems, computer control, etc., can solve problems that cannot meet the needs of the intelligent age, improve opening and closing speed and accuracy, and improve production volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

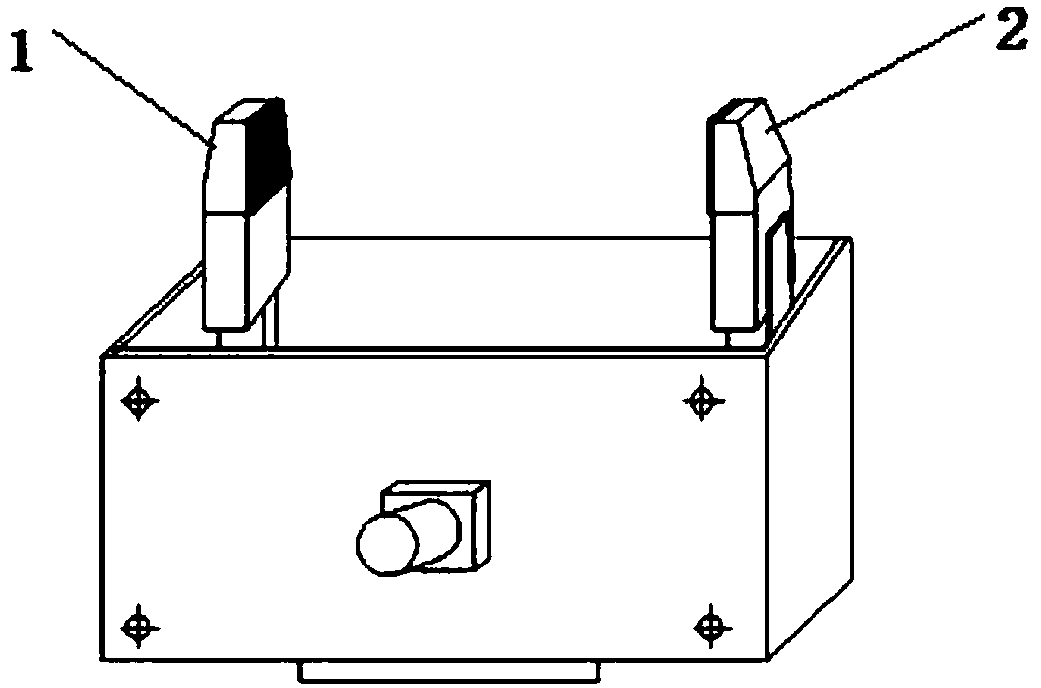

[0054] Such as figure 2 As shown, it is a kind of experimental machine clamp clamping device provided in this embodiment, including clamping machine clamp 1 and machine clamp 2, the clamping transmission is gear transmission, and the clamping drive motor is a DC brushed motor . The photoelectric switch is set inside the machine clamp A or machine clamp B, and can measure the distance between the two machine clamps.

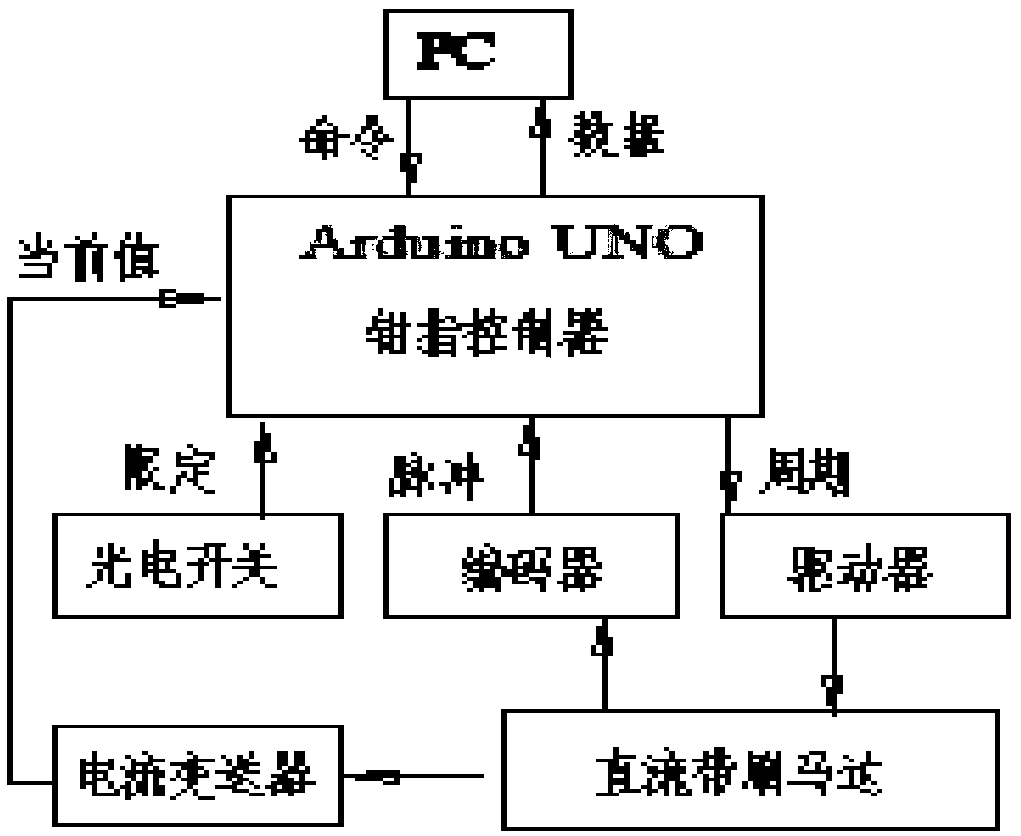

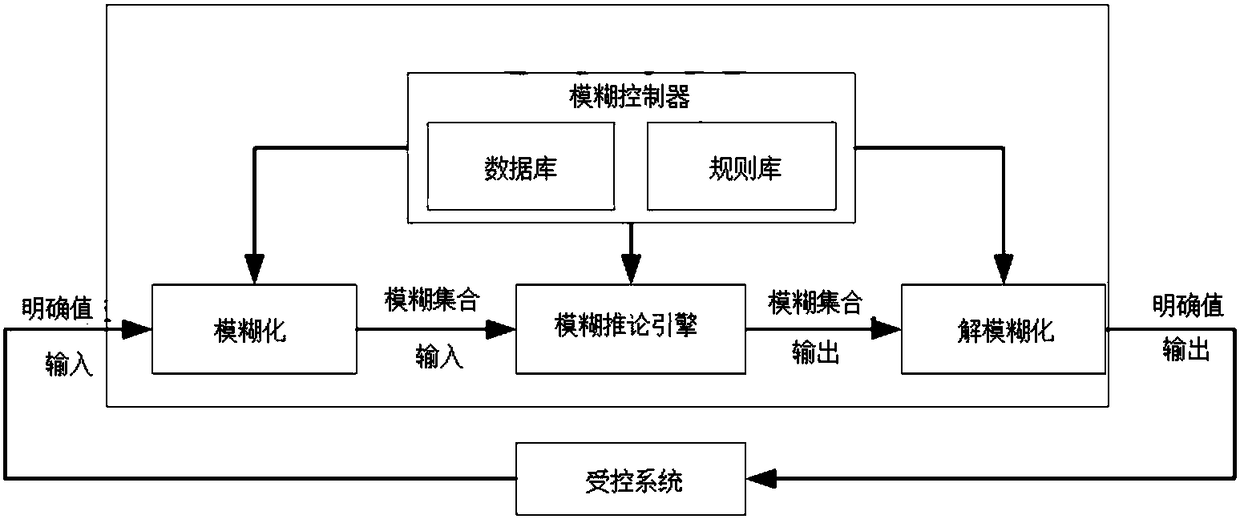

[0055] The system control process starts from the Arduino control board. The Arduino control board reads the information of the DC motor encoder and measures the current position of the DC motor. The photoelectric switch senses whether the clamp finger of the induction machine driven by the DC motor will collide with other mechanisms, and then DC motor position zero correction. The fixture control system software is set in the Arduino control board, which is converted into the moving distance of the DC motor according to the fixture command sent by the computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com