Special-shaped isolation type high-temperature-resistant fireproof cable

A fireproof cable, high temperature resistance technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance, becoming ashes, circuit short circuit, etc., to improve the high temperature resistance, prolong the fireproof time, and maintain integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

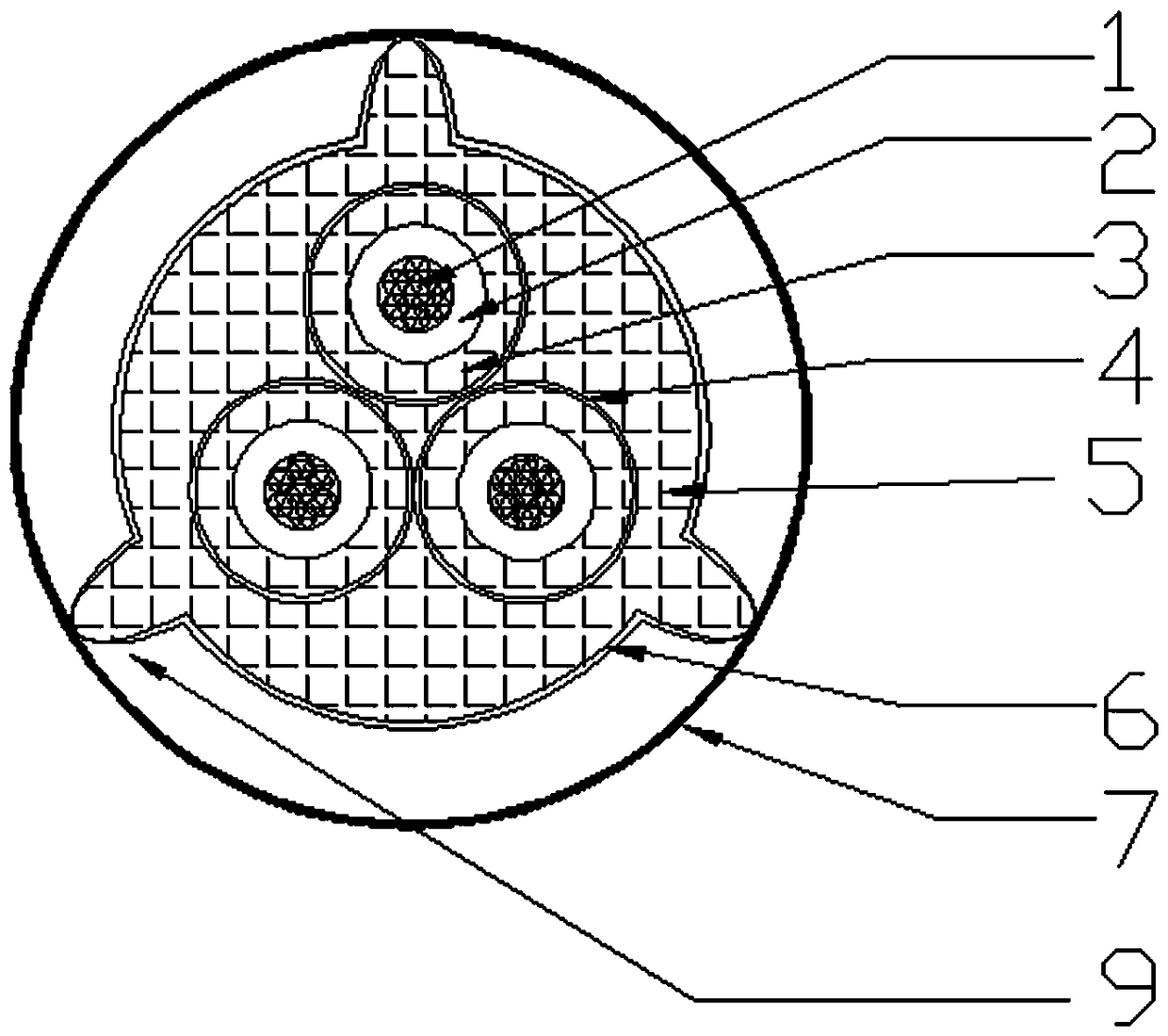

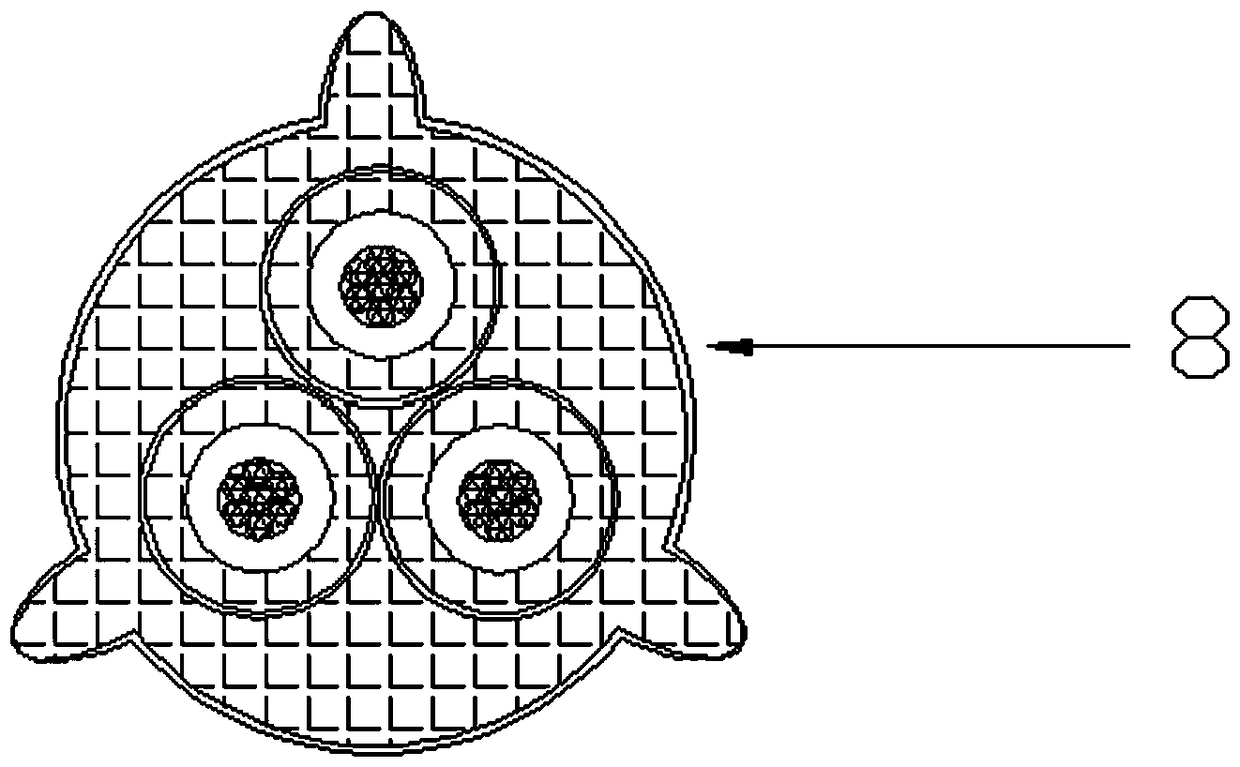

[0029] A special-shaped isolated high-temperature-resistant fireproof cable includes a cable core 8 and a sheath 7, and the sheath 7 covers the cable core 8. It is characterized in that there is a set gap between the cable core 8 and the sheath 7.

[0030] The cable core 8 includes one or more core wires, each core wire is wound with a single layer of high temperature resistant calcined mica tape wrapping layer 4, one or more core wires are extruded with an inner sheath 5, and the inner sheath A plurality of longitudinal ridges 9 are arranged on the layer 5, and the plurality of longitudinal ridges 9 and the inner sheath 5 are an integral structure of one-time extrusion molding, and the ends of the plurality of longitudinal ridges 9 are in contact with the inner wall of the sheath 7 , there is a gap between the non-protruding part and the inner wall of the sheath 7, and the inner sheath 5 is wound with an alkali-free glass fiber tape winding layer 6.

[0031] The core wire inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com