Totally-closed socket

A fully enclosed, socket technology, applied in the base/casing, contact parts, electrical components, etc., can solve problems such as fire hazards, insecurity, socket temperature rise, etc., to prevent spark flashovers, improve safety performance, and improve safety. The effect of increasing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The detailed structure of the present invention is described below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited to following embodiment, within the frame of design creativity of the present invention, various combinations are implemented, or single item is implemented all in the effective protection range Inside.

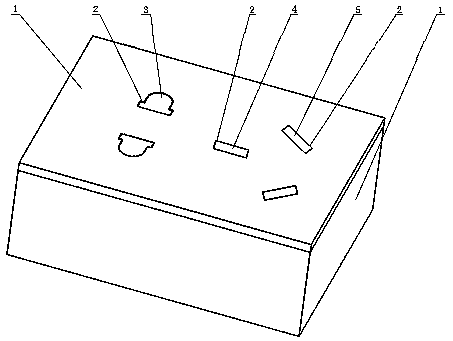

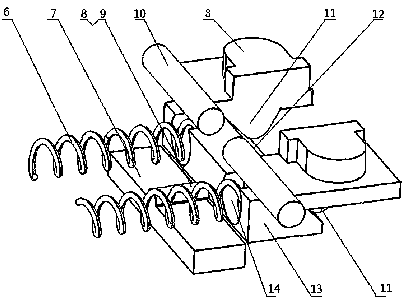

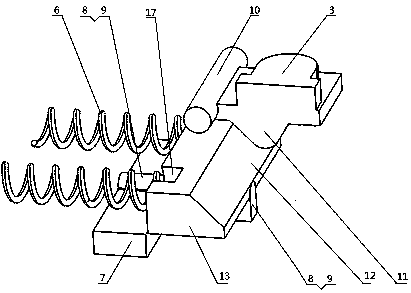

[0045] figure 1 A fully enclosed socket is described, and the present invention includes: a housing 1, a protective door device, and a movable seat device, and is characterized in that: the housing is composed of a socket cover 1 and a socket base 1; the movable seat device Including: movable seats 55, 66, 63 movable conductive sheet mounting frames 58, 68, movable seat push plates, 61, 69, springs, 54, 64, and the protective door device has bases, 7, 24, 32, 42 , 48, protection door 3, 4, 5, 15, 16, slider 13, 19, 31, base lever 11, 22, 38, spring, 6, 26, 36, 41, 52, of which: the first protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com