Preparation method of high-gradient zinc oxide piezoresistor high-resistance layer with high through-flow capacity

A varistor and high-resistance layer technology, applied in the field of high-gradient zinc oxide varistor high-resistance layer preparation, to achieve the effects of preventing cracks and flashover, increasing mechanical strength, and increasing insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In the high-resistance layer composed of only Bi, Sb, and Si elements, Sb and Si elements react with ZnO in the varistor body to form a spinel with high insulating properties. This spinel is only in contact with the body. The binding site is created, and the high resistance component inhibits the current flow through the edge of the varistor. In addition to the composition of the high-resistance layer, in the process of coating the high-resistance layer on the green body, the thickness of the high-resistance layer needs to be strictly controlled. Since the layer composition does not fully react with ZnO, it will fall off, and the performance of the high resistance layer cannot be fully exerted. In the high-resistance layer composed of Bi, Sb, and Si elements, moderately adding ZnO can make Si and Sb in the high-resistance layer react with ZnO, and after co-sintering with the varistor green body, a dense high-resistance layer is formed and adhered to The side of the var...

Embodiment 2

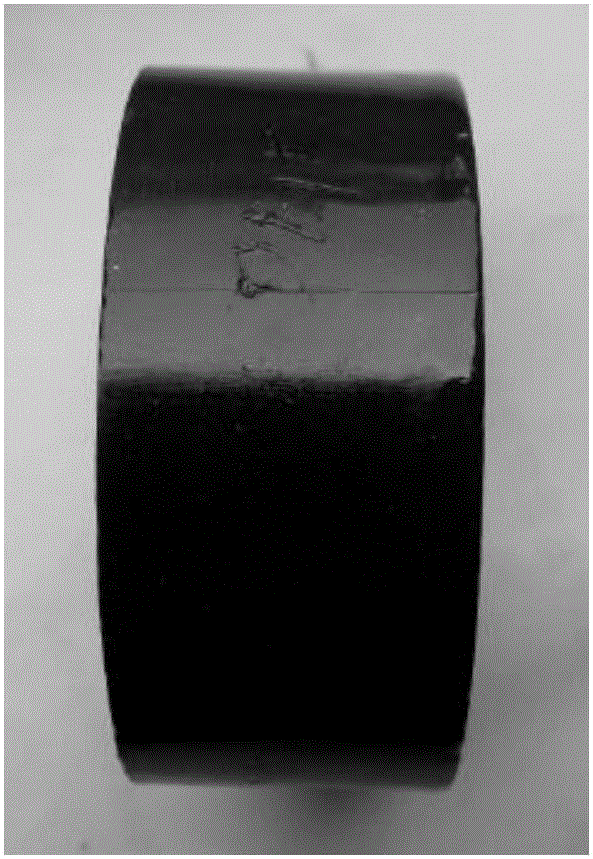

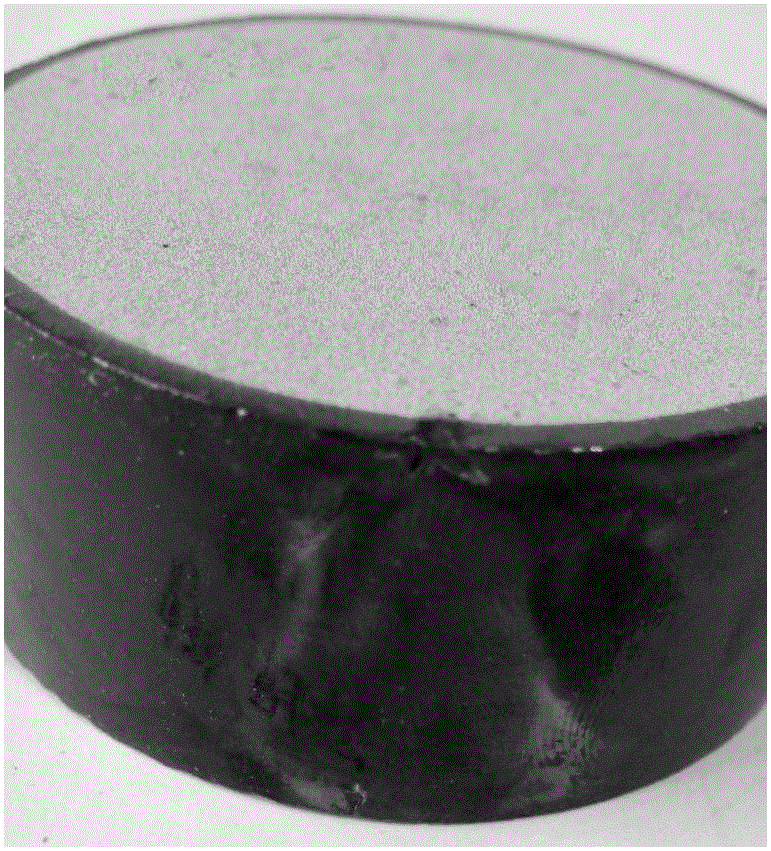

[0057] figure 1 It is Li-containing described in the present invention + Ionic high resistance layer formula table, such as figure 1 As shown, the raw materials are figure 1 Mix as shown, pour into a ball mill jar, add deionized water that is one-tenth of the weight of the powder, and mill for 8 hours, then add PVA with a concentration equal to the weight of the powder, and continue to mill for 2 hours, adding an appropriate amount of Antifoaming agent, remove the air bubbles mixed with PVA during the ball milling process, the ball milled high resistance layer slurry has no agglomeration phenomenon, and finally the powder can be fully and evenly dispersed in the binder, after the ball milling, filter out the prepared The slurry is stored in a container for use. The ball-milled high-resistance layer slurry is coated by hand, and evenly applied to the side circumference of the piezoresistor body after degluing with a row brush, and dried, and the body coated with the high-res...

Embodiment 3

[0059] In Example 2, the sintered ZnO varistor valve plate was subjected to grinding, drying, aluminum electrode spraying and polyester insulating varnish roller coating, and then the electrical performance test of the valve plate was performed.

[0060] figure 2 Is the Li described in the present invention + Recipe high resistance layer electrical parameter table, such as figure 2 As shown, the varistor voltage E1mA, leakage current IL and residual voltage ratio K before and after heat treatment are listed in figure 2 Among them, the varistor voltage did not change significantly before and after heat treatment, the leakage current increased significantly by 3.66 times, and the residual voltage ratio decreased significantly from 1.75 before heat treatment to 1.62.

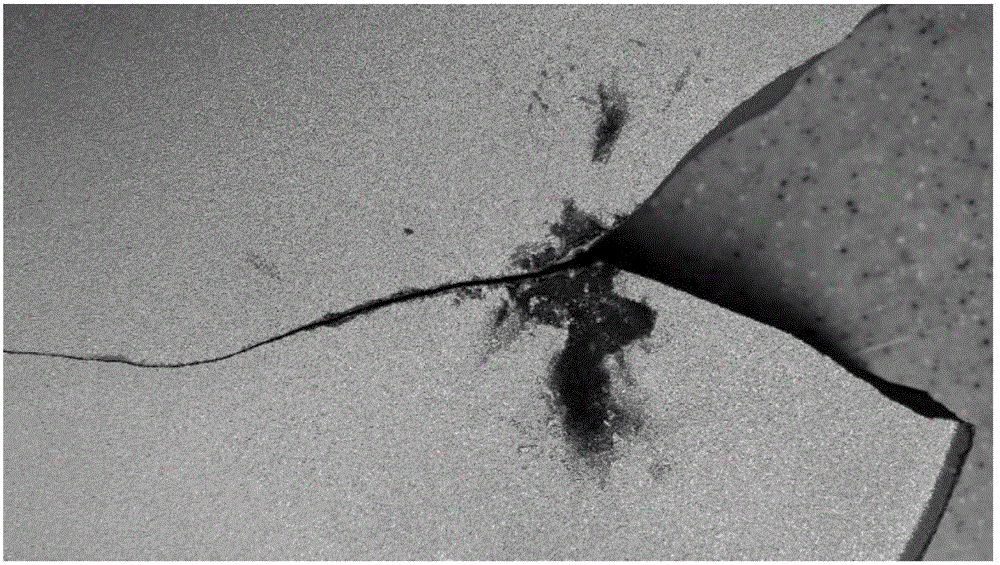

[0061] When the current exceeds 300A, cracks and ruptures will appear in the test sample, indicating that the lithium-containing + The high-resistance layer formula of the ionic formula and the high-resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com