Film forming device for producing plastic soft packaging films

A technology of flexible packaging film and film forming device, which is applied in the field of film forming device for producing plastic flexible packaging film, which can solve the problems of rapid cooling of plastic film, increase the work intensity of operators, and inconvenient movement, so as to save manpower and improve portability. Sex, the effect of improving the efficiency of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

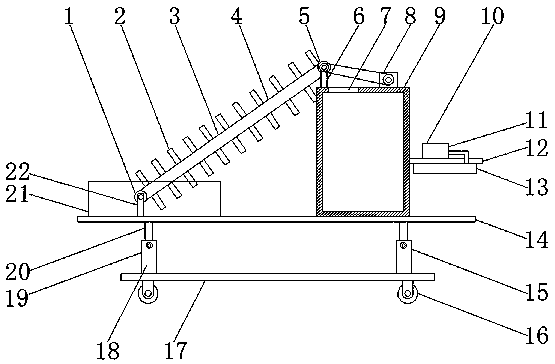

[0015] combine figure 1 , in an embodiment of the present invention, a film forming device for producing plastic flexible packaging films, comprising a feeding device 4, a feed port 7, a motor 8, a film forming machine main body 9, a cooling device 10, a horizontal plate 14, a first Height adjustment device 15, universal wheel 16, bottom plate 17, second height adjustment device 18 and receiving groove 21, said bottom plate 17 is provided with horizontal plate 14 directly above the top, and the bottom of horizontal plate 14 is symmetrically provided with first height adjustment device 15 And the second height adjustment device 18, the second height adjustment device 18 includes a cylinder 19 and a rod 20, the cylinder 19 is fixedly installed on the top of the bottom plate 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com