Baijiu distillation temperature and alcohol by volume control method

A control technology and alcohol content technology, applied in the field of liquor brewing production equipment, can solve problems such as high technical level requirements and unstable product quality, and achieve the effects of reducing production costs, stable and controllable product quality, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

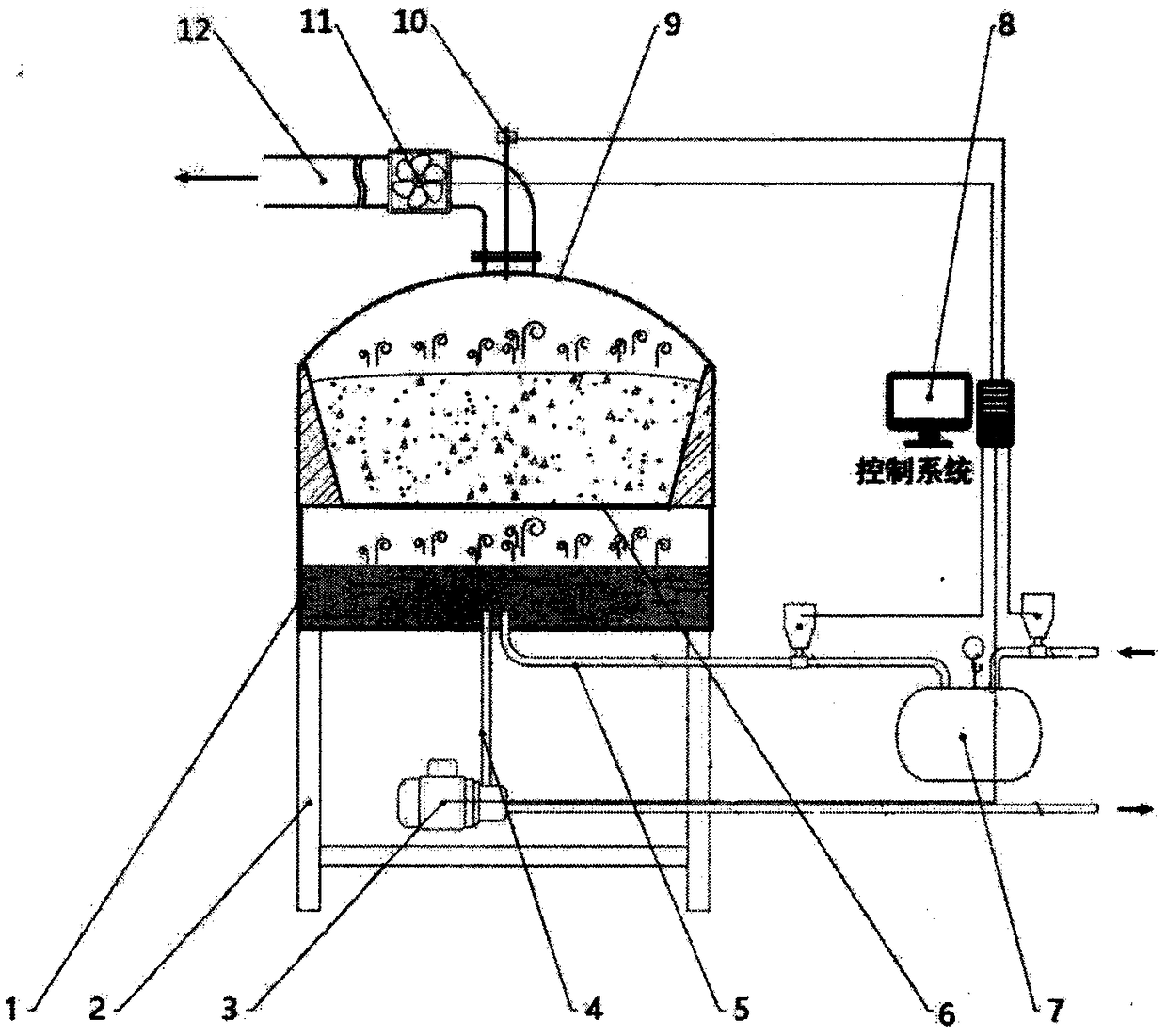

[0014] Depend on figure 1 It can be seen that the present invention includes a frame body, a steam surge tank, a steam pipe, a steam heating tank, a transmission plate chain, an air guide pipe and a control system. The transmission plate chain divides the steam pressure tank into upper and lower parts. The lower part of the transmission plate chain is the water layer, and the upper part of the transmission plate chain is the wine unstrained spirits. A temperature sensor is installed on the air outlet at the center; the temperature sensor sends real-time temperature data to the control system, and the control system controls the control valve on the steam pipe to control the amount of steam entering according to the data.

[0015] The bottom of the steam heating tank is connected with a drainpipe, and a sewage suction pump is arranged on the drainpipe.

[0016] The top of the steam heating tank is a sealed cover.

[0017] An induced draft fan is arranged on the air duct.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com