Low-temperature deposition equipment provided with auxiliary positive pole

A technology of auxiliary anode and deposition equipment, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of substrate damage, substrate temperature rise, etc., to achieve low cost, low thermal effect, and great economy effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

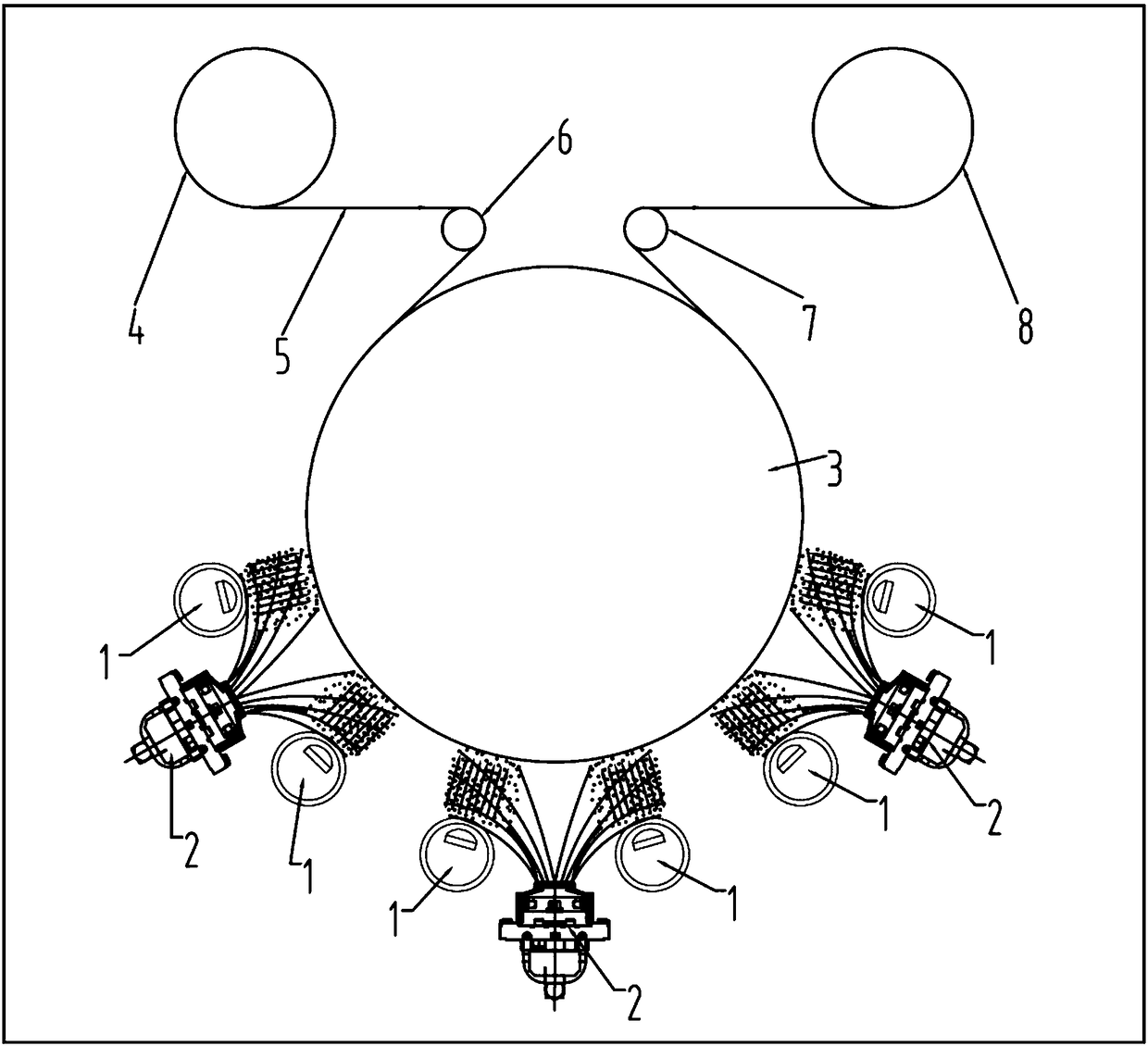

[0023] to combine figure 1 As shown, the low-temperature deposition equipment equipped with auxiliary anodes includes a vacuum chamber and flexible substrates placed in the vacuum chamber, unwinding rollers, first guide rollers, water-cooled drums, second guide rollers, winding rollers, and multiple pairs of magnetrons. target, multiple auxiliary anodes. The flexible base material goes around the unwinding roller, the first guide roller, the water cooling drum, the second guide roller and the winding roller in sequence; The running route of the flexible substrate is set in sequence. Multiple pairs of magnetron targets are arranged sequentially along the circumferential direction of the circumferential surface of the water-cooling drum, that is, each pair of magnetron targets is evenly arranged on an outer arc of the circumferential surface of the water-cooling drum. An auxiliary anode is arranged between each pair of magnetron targets, such as figure 1 As shown, two adjacen...

Embodiment 2

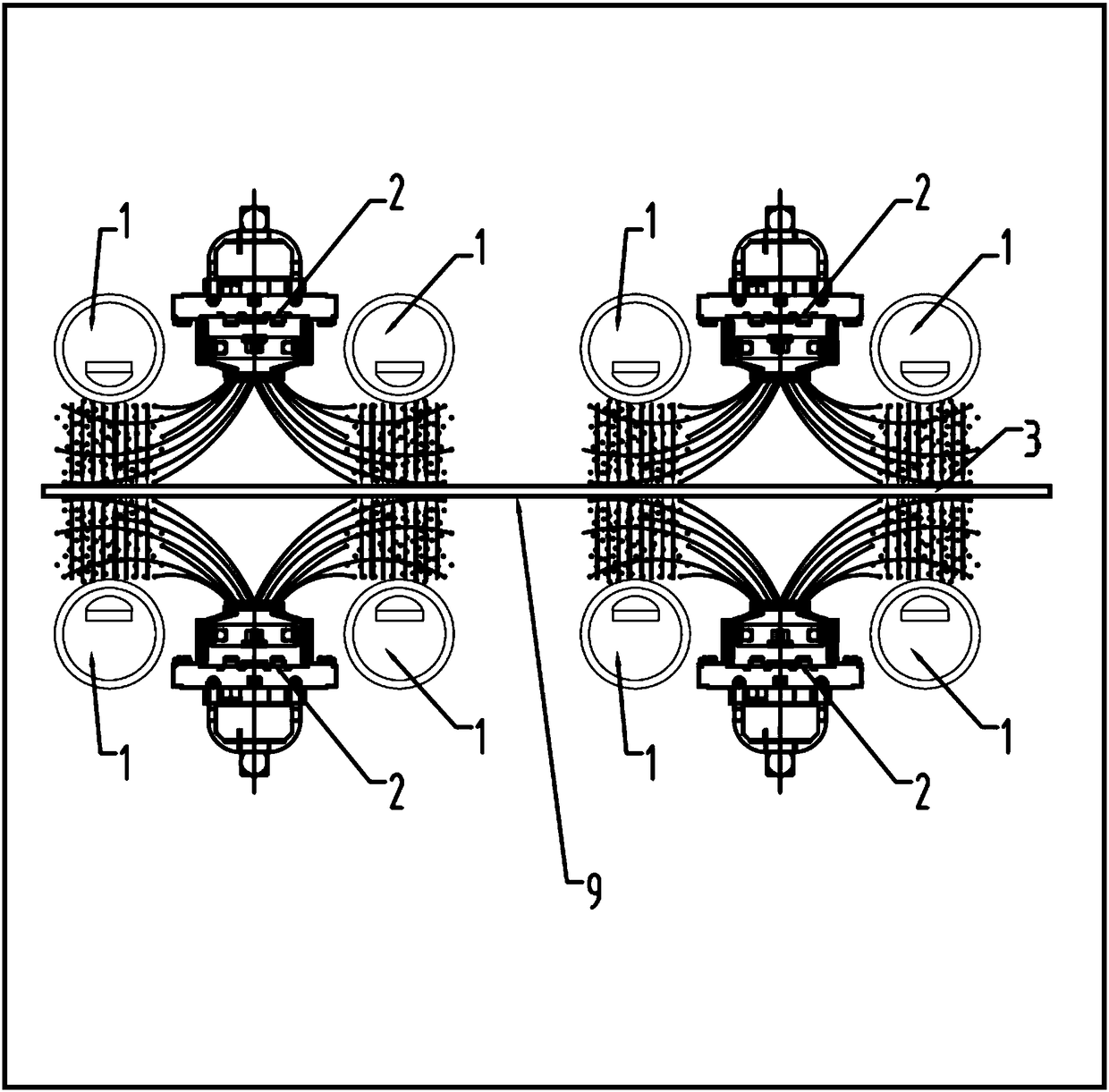

[0031] to combine figure 2 As shown, the low-temperature deposition equipment equipped with auxiliary anodes includes a vacuum chamber and a sheet substrate all arranged in the vacuum chamber, a conveying mechanism, multiple pairs of magnetron targets, and multiple auxiliary anodes. The sheet substrate is placed on the conveying mechanism, and the conveying mechanism conveys the sheet substrate. There are multiple pairs of magnetron targets above and below the sheet substrate. The multiple pairs of magnetron targets above the sheet substrate and the multiple pairs of magnetron targets below The magnetron targets are arranged sequentially along the conveying direction of the conveying mechanism, and an auxiliary anode is arranged between each pair of magnetron targets. Such as figure 2 As shown, two adjacent magnetron targets are called a pair of magnetron targets, and an auxiliary anode is arranged between the two magnetron targets. Each pair of magnetron target and auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com