Prefabricated assembled type upright post connecting structure and construction method thereof

A prefabricated assembly and column technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of large size, poor structural seismic performance, and poor cooperative mechanical performance, so as to reduce weakening and stress Influence, improve seismic performance, save material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

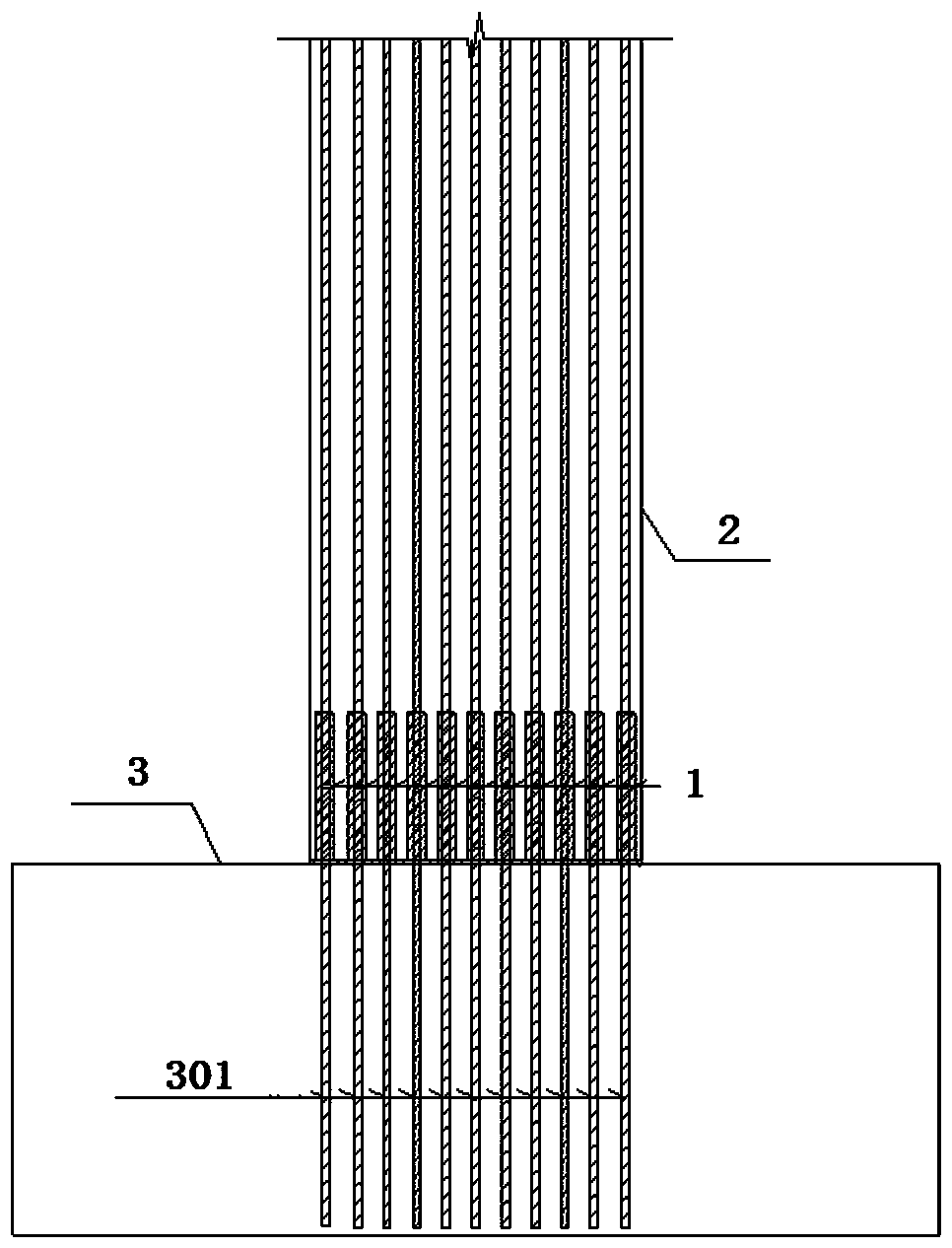

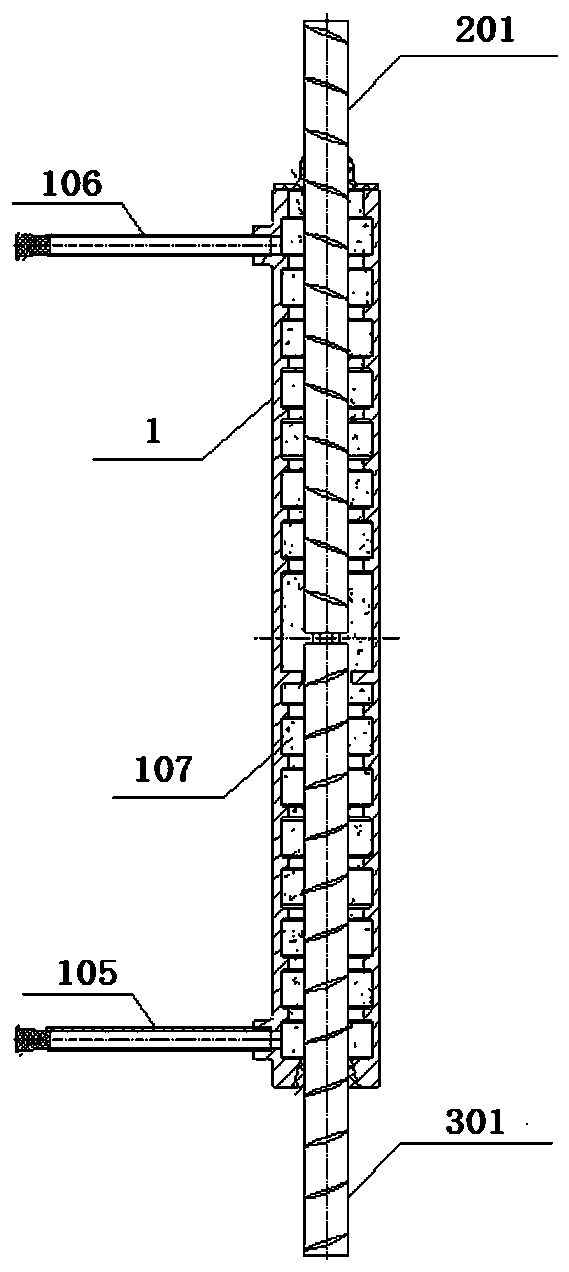

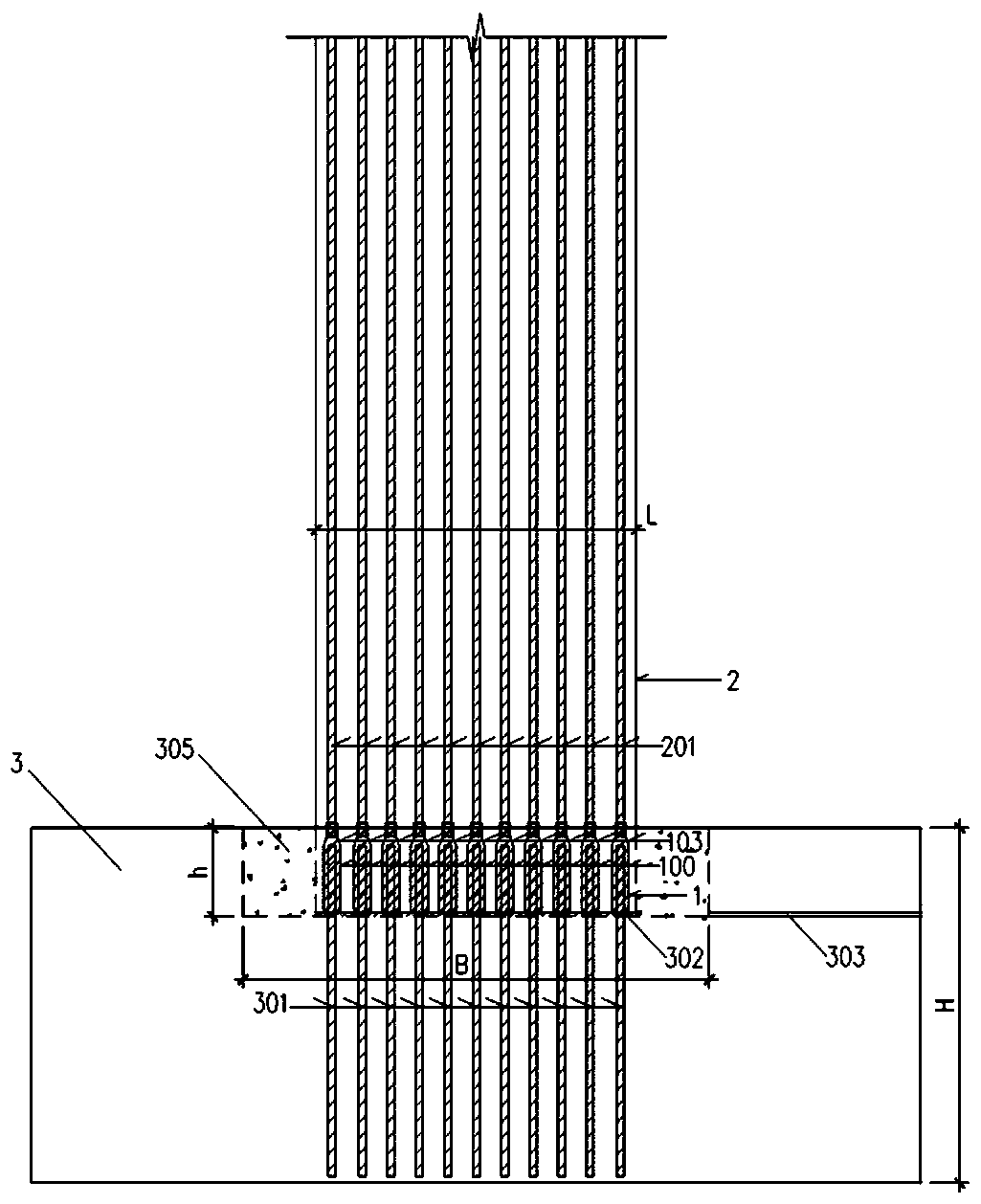

[0040] The figure includes: steel bar connection sleeve 1, prefabricated column 2, cap 3, columnar body 100, internal thread section 101, grouting sleeve section 102, conical transition section 103, inner cavity 104, grouting hole 105, grouting Hole 106, high-strength non-shrinkage cement-based grouting material 107, column reinforcement 201, cap groove 300, column connection reinforcement 301, drain hole 303, structural short reinforcement 304, post-cast concrete 305.

[0041] Such as Figure 3-Figure 6 A prefabricated assembly column connection structure is shown, including: a steel bar connection sleeve 1 , a prefabricated column 2 , and a cap 3 .

[0042] The steel bar connection sleeve 1 includes a columnar body 100, which is made of cast steel or high-quality ductile iron, and is divided into three section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com