Movable sealed intelligent maintenance and construction method for cast-in-place beams constructed by cantilever method

A construction method and mobile technology, which is applied in the field of cantilever method construction cast-in-place beam mobile sealing intelligent maintenance construction, which can solve the problems of insufficient maintenance, inability to maintain, and unintelligent maintenance methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

[0027] Main principle and method of the present invention:

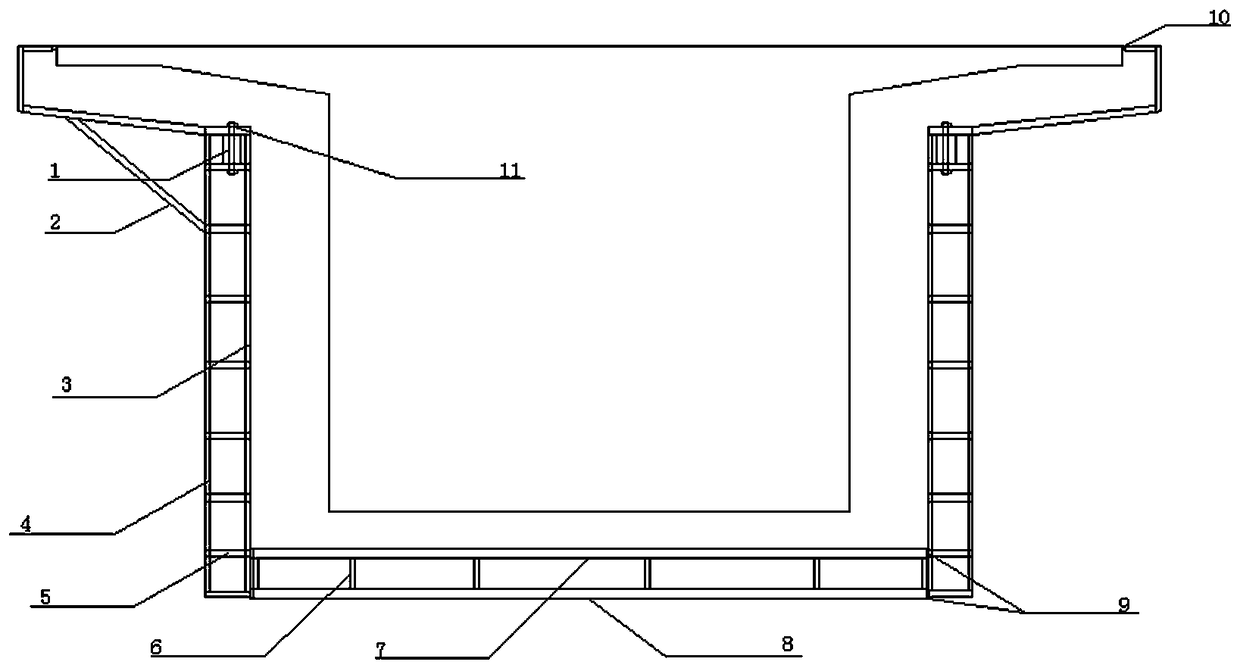

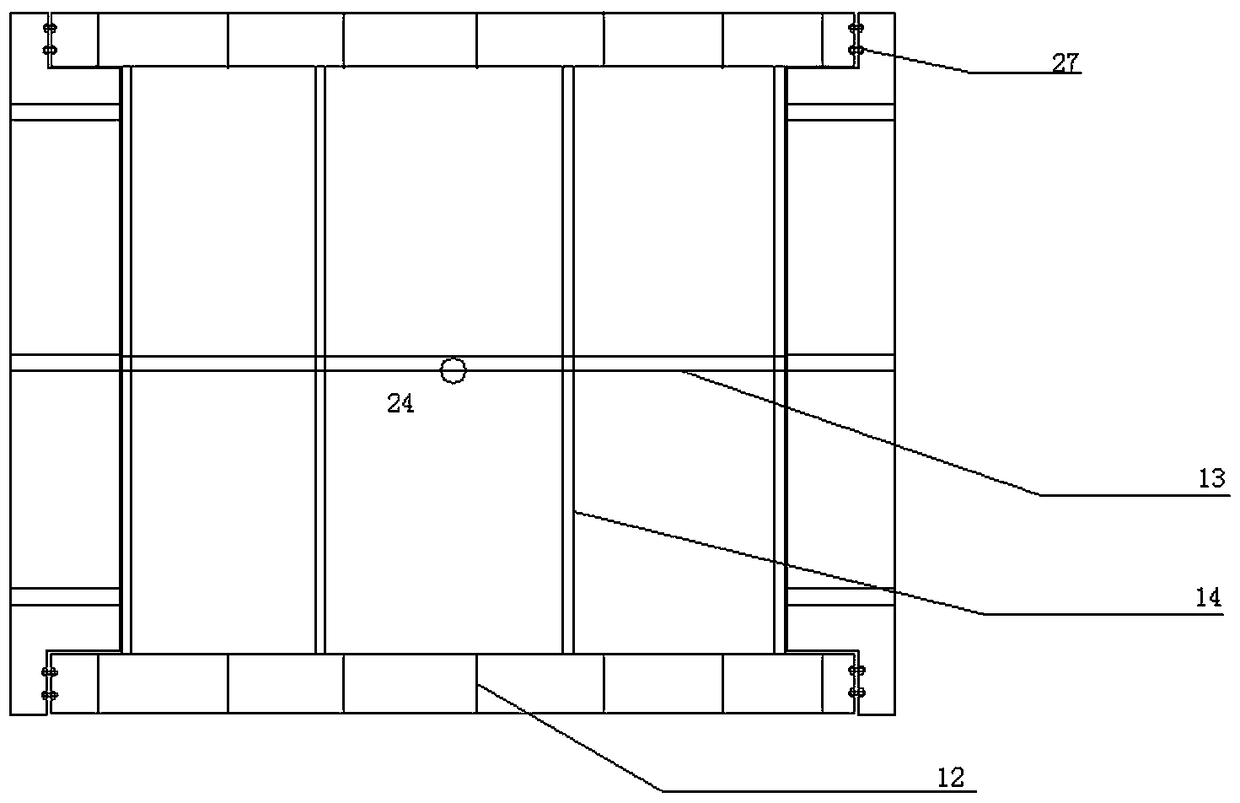

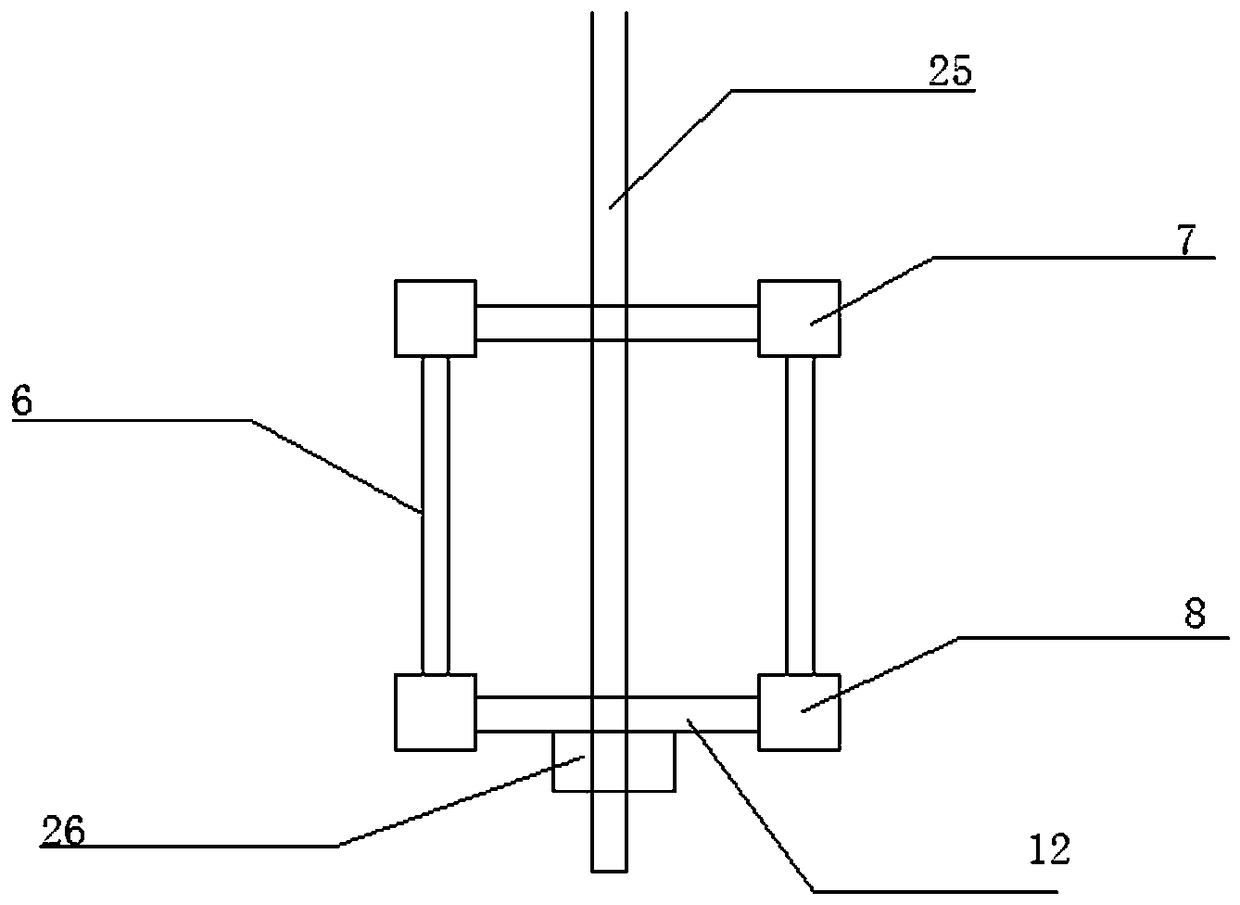

[0028] 1) The composition of the intelligent maintenance system mainly includes a sealed and movable maintenance device, a temperature, humidity and concrete hydration heat monitoring system, a water suction pump, a solenoid valve, a speed-adjusting frequency converter, PLC and a power distribution system; through the cooperation of various systems, Real-time monitoring of temperature, humidity and heat of hydration, timely adjustment of the water supply and spray volume of the sprinkler system, to realize intelligent maintenance of the bottom web of the cast-in-place beam; the combination of the mobile maintenance device and the hanging basket structure realizes that the maintenance device follows the construction progress shift.

[0029] 2) The structure of the sealed movable maintenance device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com