Telescopic control valve, multi-oil-cylinder sequential telescopic control mechanism and multi-oil-cylinder driving device

A telescopic control, oil cylinder technology, applied in fluid pressure actuating devices, mechanical equipment, transportation and packaging, etc., can solve the problems of high manufacturing cost of single-cylinder bolts, difficult structural arrangement, large boom section, etc., to reduce energy consumption , The effect of improving the processing difficulty and reducing the weight of the boom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

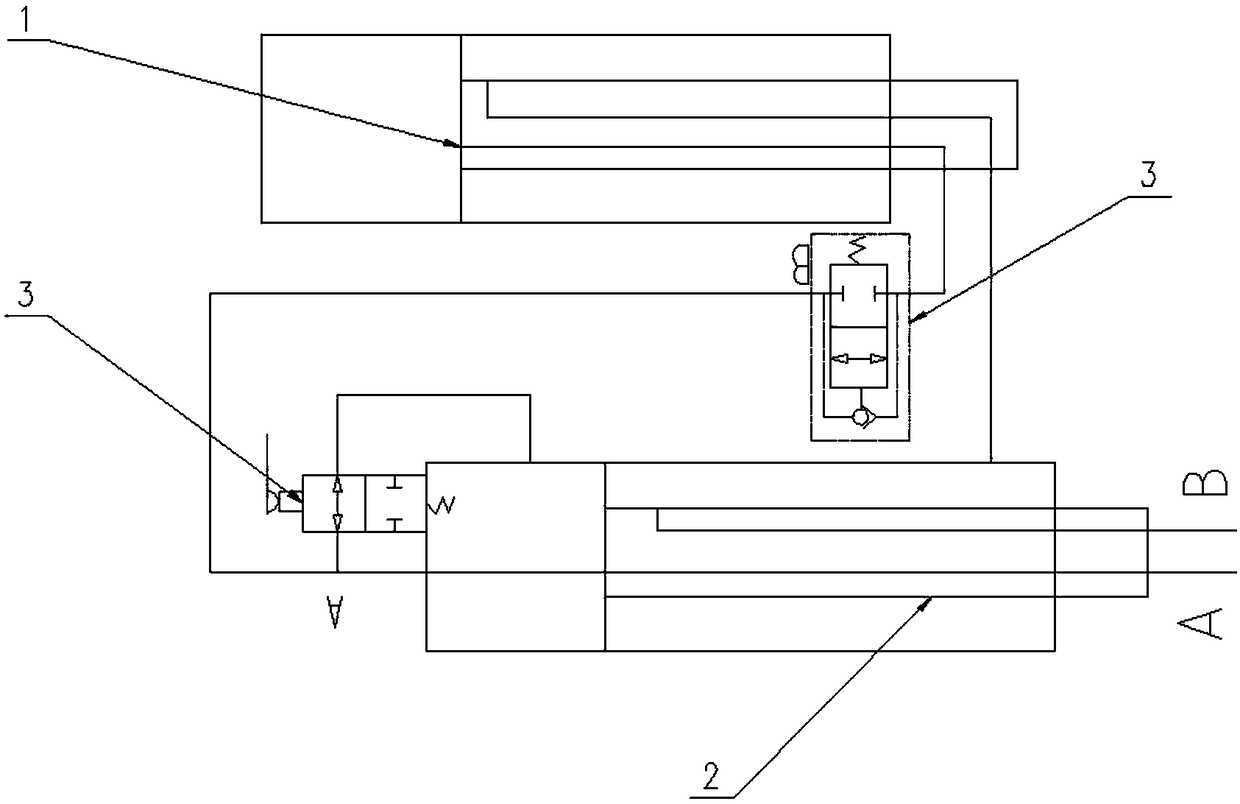

[0053] The present invention is described by taking the sequential expansion and contraction control mechanism of double oil cylinders as an example.

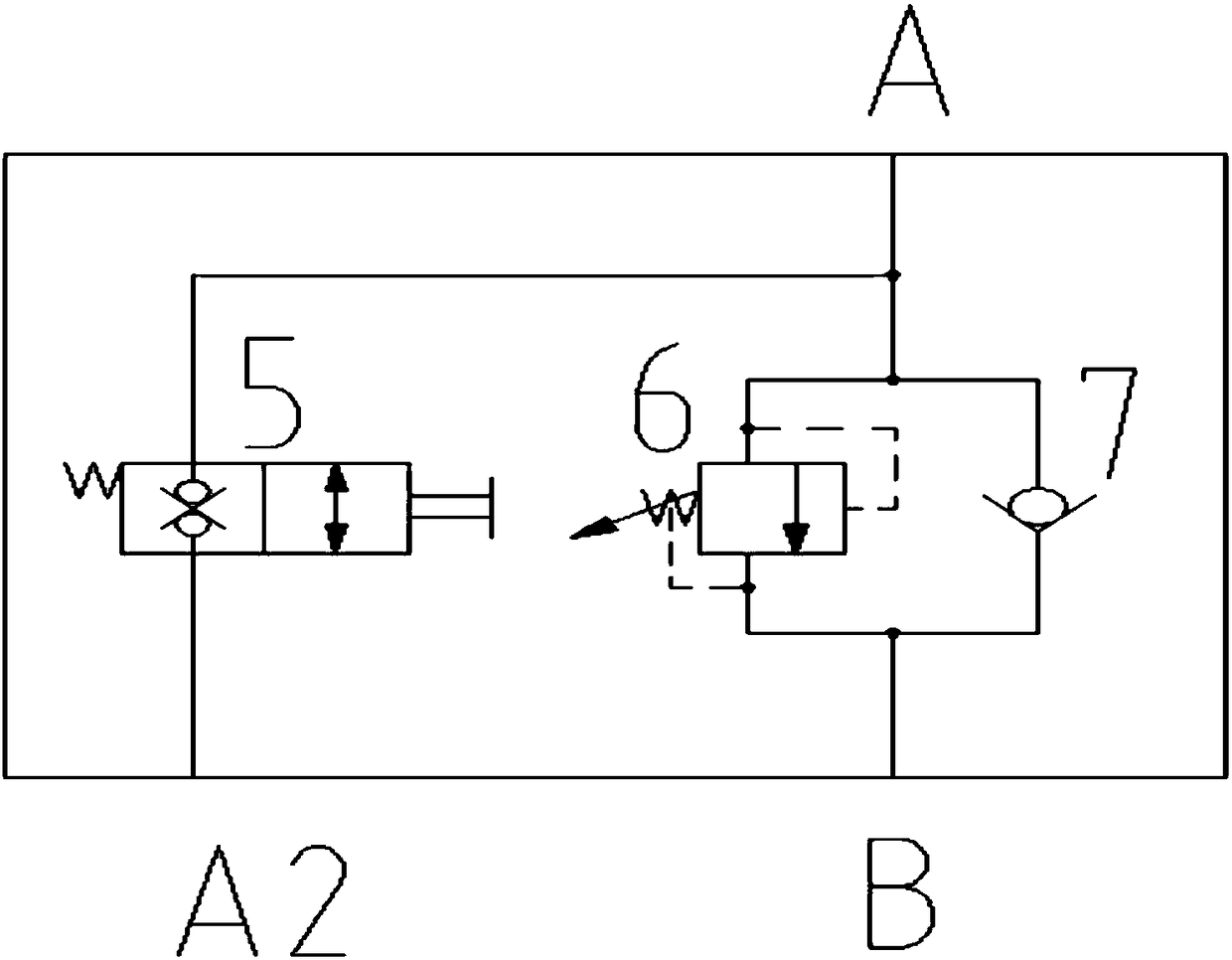

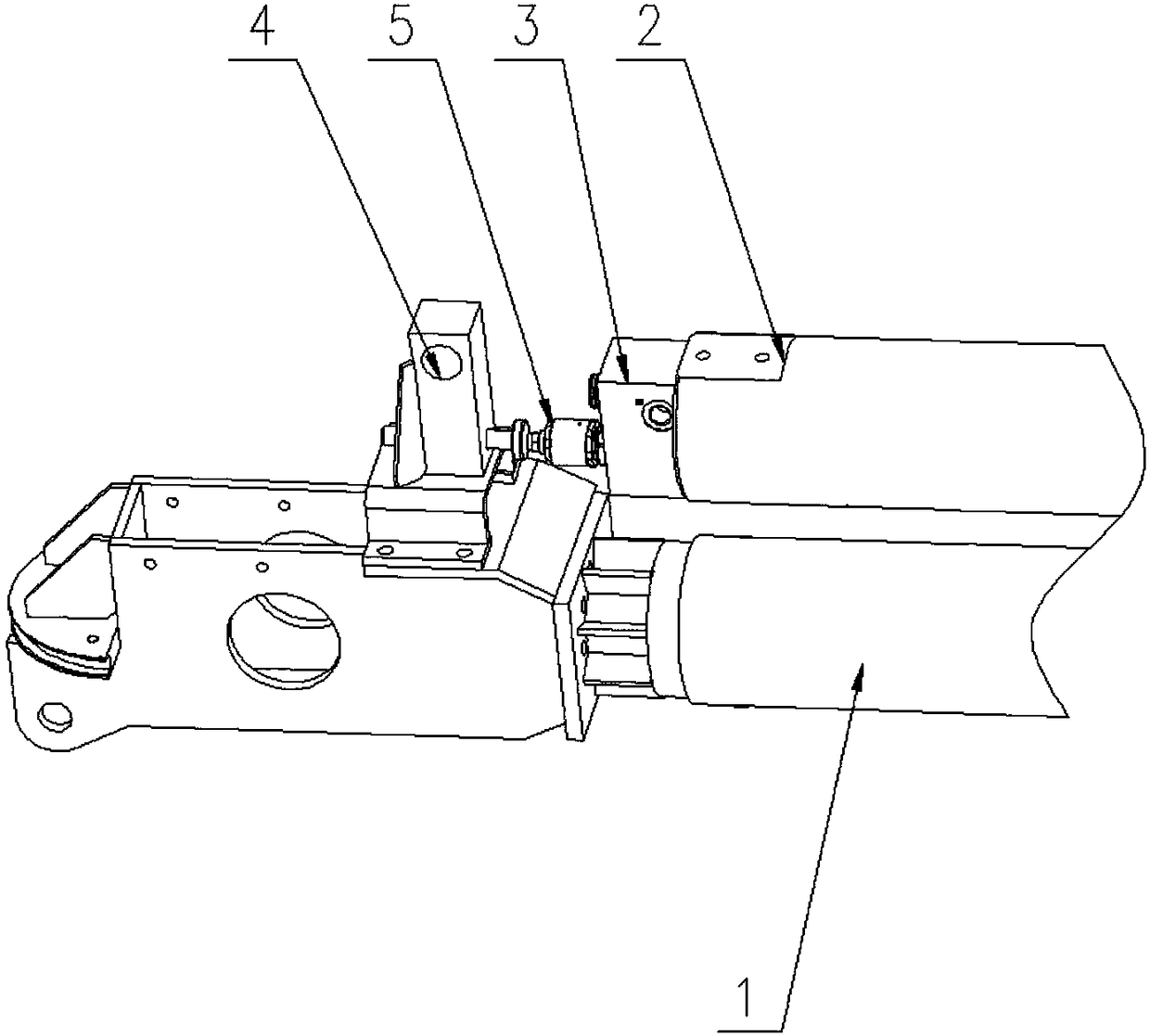

[0054]The telescopic control valve includes a valve body 8 and a mechanical touch switch 5, an overflow valve 6 and a one-way valve 7 arranged in the valve body 8, and the mechanical touch switch 5, the overflow valve 6 and the one-way valve 7 are connected in parallel, the mechanical touch switch 5 controls the hydraulic oil inlet and outlet channels of the first oil cylinder, and the overflow valve 6 and the one-way valve 7 control the hydraulic oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com