Composite kiln

A kiln and forehearth technology, which is applied in the field of stale waste management, can solve problems such as the difficulty of stale waste management, and achieve the effects of solving management difficulties and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

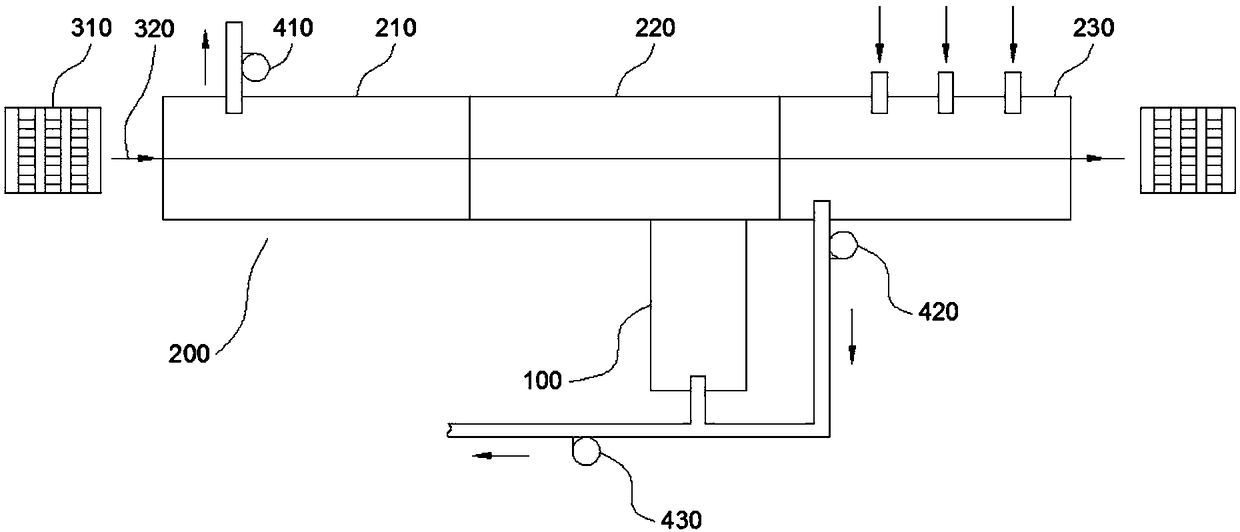

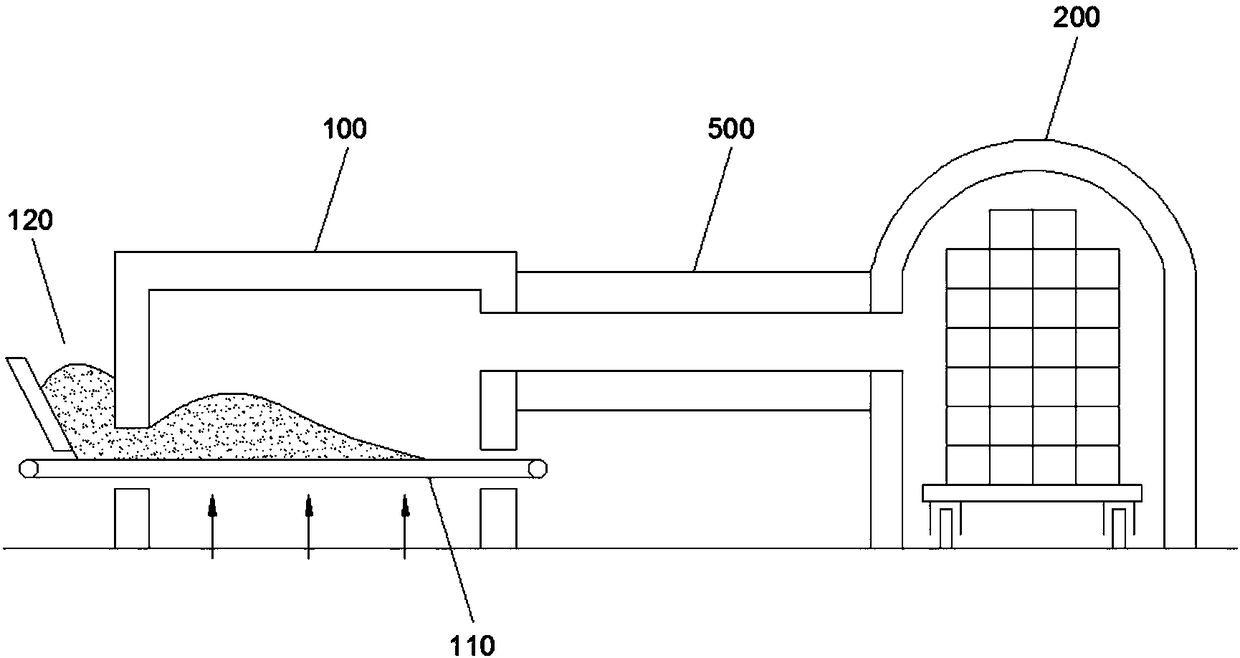

[0043] In the optional scheme of this embodiment, such as figure 1 As shown, a kind of compound furnace kiln provided in this embodiment comprises a forehearth 100 and a tunnel kiln 200; It is used for firing finished bricks with humus as raw material; the tunnel kiln 200 includes a preheating section 210 , a calcination section 220 and a cooling section 230 connected in sequence; the forehearth 100 communicates with the calcination section 220 .

[0044] In this embodiment, the setting of the forehearth 100 ensures the effective combustion of the RDF fuel made of mineralized waste light combustibles, and the concentrated leachate is sprayed and burnt through the forehearth 100 to provide the refractory leachate The heat generated by fuel combustion in the forehearth 100 is directly introduced into the tunnel kiln 200 as supplementary heat for brick calcination. The combination of the tunnel kiln 200 and the forehearth 100 ensures that the heat generated by fuel combustion can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com