Microchannel gas discharging and water draining device for large-capacity heat storage sink

A technology for thermal storage pools and drainage devices, which is applied to thermal storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of damaging the barrier layer and the large span of the floating thermal insulation cover on the top, and achieve the effect of avoiding damage and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

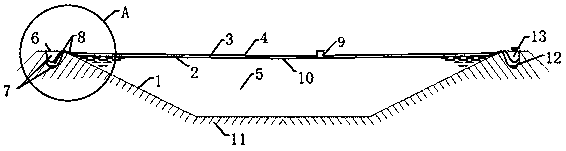

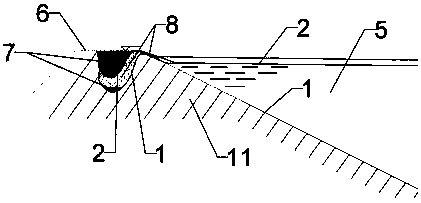

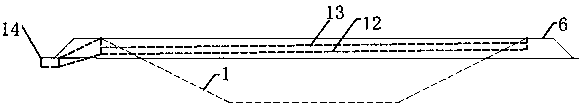

[0033] Such as Figure 1-2 As shown, a large-capacity hot water storage pool includes a hot water storage body 5, the liquid level of the hot water storage body 5 is lower than the level of the surrounding cofferdam 6, and the side surface of the hot water storage body 5 is arranged between the soil or other supporting materials 11 The side flexible barrier layer 1, the side flexible barrier layer 1 extends out of the water body 5, reaches or approaches the height of the cofferdam 6 and then descends to form a bottom groove 12 under the cofferdam 6, and the bottom of the bottom groove 12 is filled with a high-porosity porous medium 7. Such as but not limited to gravel; the top of the bottom groove 12 is filled with a low-porosity porous medium 8, such as tiny stones or sand. The top flexible barrier layer 2 is arranged between the liquid surface of the hot water storage body 5 and the top floating insulation layer 3, and the top flexible barrier layer 2 extends out of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com